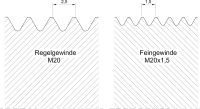

Fine thread

A screw (or nut ) with a fine thread has a narrower thread profile compared to a regular thread. To distinguish it, it is marked in addition to the outer diameter with the dimension of its - also smaller - pitch . For example, the standard thread M 20 has a pitch of 2.5 mm. Fine threads with the same outside diameter of 20 mm are M 20 × 2; M 20 × 1.5 (see picture); M 20 × 1 or with an even smaller pitch (all standardized pitch dimensions are possible).

Fine threads can be found in the metric ISO thread and the Whitworth thread , as well as in the American Unified Thread Standard .

use cases

Applications for fine threads are:

- Adjusting screws , e.g. B. of measuring devices , as they allow a more precise setting because of the smaller stroke (they are more sensitive).

- if there is little space available for the thread in the radial direction, e.g. B. if the thread has to be attached to a hollow component with a small wall thickness, so that the threads of a standard thread would cut too deep.

- To increase the load-bearing capacity of the screw. A screw fine thread leads to a larger core diameter (load-bearing cross-section of the bolt).

Because of the lower pitch, the self-locking is better than with standard thread. Under certain circumstances you can do without a screw lock.

The sensitivity and self-locking of threads are explained using two further illustrations. Just imagine the thread unwound.

Extract from DIN 13-2

Size in mm.

| designation | Flank ø | Thread depth | Core-ø nut |

Core hole drilling |

|

|---|---|---|---|---|---|

| bolt | mother | ||||

| M 5 x 0.25 | 4.84 | 0.15 | 0.14 | 4.73 | 4.75 |

| M 5 x 0.5 | 4.68 | 0.31 | 0.27 | 4.46 | 4.50 |

| M 6 x 0.75 | 5.51 | 0.46 | 0.41 | 5.19 | 5.25 |

| M 8 × 1 | 7.35 | 0.61 | 0.54 | 6.92 | 7.00 |

| M 10 × 1.25 | 9.51 | 0.46 | 0.41 | 9.19 | 9.25 |

| M 12 × 1.50 | 11.51 | 0.46 | 0.41 | 11.19 | 11.25 |

| M 20 × 1.5 | 19.35 | 0.61 | 0.54 | 18.92 | 19.00 |

| M 20 × 1.5 | 19.03 | 0.92 | 0.81 | 18.38 | 18.50 |

Difference to standard thread

The standards (for metric threads ISO 261) specify not only the standard threads but also so-called fine threads, which are characterized by a lower pitch (height of one thread revolution):

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

literature

- Ulrich Fischer: Metal table book. 44th edition. Verl. Europa-Lehrmittel Nourney, Vollmer, 2008, ISBN 978-3-8085-1078-0

- Metal technology learning fields. Basic knowledge. 3. Edition. Bildungsverlag Eins, February 19, 2007, ISBN 978-3427550303