Rotary vane pump

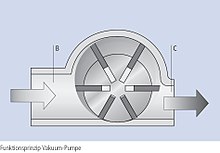

A rotary vane pump or vane pump is a positive displacement pump for gases and liquids for suction or pressure tasks. It consists of a hollow cylinder (stator) in which another cylinder (rotor) rotates. The axis of rotation of the rotor is arranged eccentrically to the stator, the rotor touches the inner wall of the stator between the inlet and outlet openings. This point is the dividing point between the suction and pressure chamber. Vacuum pumps based on this principle are often called oil pumps in chemical laboratories because they usually require large quantities of lubricating oil.

Working method

One or more guides , usually arranged radially , are incorporated into the rotor (2) . The rotary valve (3) sit in these guides . These slides divide the space between the stator and rotor into several chambers. In order to compensate for the change in distance between rotor (2) and stator (1) during one revolution, the rotary valve can move in the guides. They are usually pressed against the inner wall of the stator by a spring (4) attached to the bottom of the slot. To ensure lubrication , a small pool of lubricating oil is usually created inside the pump through which the rotary vanes run. The pump therefore always delivers a small part of the lubricant . This is usually separated in the outlet tract and fed back to the lubricant reservoir. Lubricant-free rotary vane pumps are also available.

The name oil pump , which is often used in chemical laboratories for vacuum pumps of this type, is derived from the lubricant .

A housing with an elliptical cross-section serves to equalize the pressure of the rotor in chamber (4).

Constructive and functional details

Simple vacuum pumps are actually built practically exactly as shown in the principle drawing. There is a variable volume that has no connection to either the inlet or outlet, the so-called conveyor tract . During pumping, the pumped medium is diluted and recompressed in the closed conveyor tract . When used as a vacuum pump, however, a gas is conveyed that is usually very dilute. The work required for diluting or compressing the medium in the delivery tract is therefore small, so that it can be accepted in favor of a simple construction of the vacuum pump. For other applications, especially the pumping of incompressible media such as liquids, remedial measures must be taken through design measures - usually by enlarging the inlet and outlet openings:

- Inlet opening approx. Up to the 90 ° mark

- Outlet opening approx. From the mark 270 °

With the control times adjusted by the enlarged openings , the conveyor tract and with it the problem disappear .

Gas ballast

When operating with gas ballast, air is let into the pump chamber through a small leak valve before the gas is compressed. This lowers the compression ratio so that the gas is expelled before the condensation point is reached.

The achievable minimum pressure of the system is slightly increased, at the same time volatile substances are expelled from the pump oil by the greater flow, or tend to be less likely to separate in it (see above). The valve can often be closed manually so that the user can choose between the operating modes. The oil mist, which is increasingly emitted during operation with gas ballast, is captured in the separator and fed back, which temporarily clouds the pump oil.

advantages

- low volume flow pulsation

- medium noise emission

- can work in both directions of flow

- Adjustable volume

- inexpensive

- very efficient

disadvantage

- high wear

- only suitable for medium pressures (up to a maximum of approx. 300 bar )

Applications

- Vacuum pump for the rough and fine vacuum range (1,000 - 0.001 mbar, with a delivery rate of approx. 20–500 m³ / h)

- Hydraulic pump (e.g. power steering, active seats in automobiles)

- Steam engine (some modern steam engines work like an inverted vane pump)

- Compressors in air conditioning systems

See also

Web links

swell

- ↑ Gas ballast opening of an oil pump. In: bcp.fu-berlin.de