Steam engine

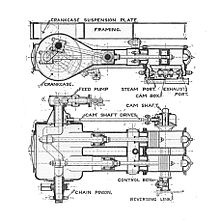

A steam engine is a single or double-acting piston steam engine , running fast with up to 1500 revolutions / min. In contrast to the classic steam engine, a steam engine and all its components are housed in a compact housing very similar to that of a diesel engine. With a steam engine, a modern, clutch and gearless vehicle drive can be implemented. Today it is used primarily as an industrial steam power plant in the lower power range (approx. 100 to 1,000 kW) for applications below the typical power range of steam turbines.

Building principles

Boilers for steam engines can be operated with all common liquid and solid fuels, including wood and biogas, depending on their design. With a pore burner , very low pollutant emissions and an almost free choice of (liquid or vaporizable) fuel can be combined with a relatively high degree of efficiency . In this respect, such systems are comparable to a modern diesel engine . This is accomplished by steam pressures up to 80 bar , and steam temperatures of about 450 to 500 ° C achieved.

Due to the high steam temperatures, there were initially problems due to the necessarily oil-free operation. Thanks to special materials made of carbon and ceramic, this seems to have been resolved in the meantime, but the service life of the chemically and physically heavily loaded pore burner (a ceramic or metal sponge in which combustion takes place without an open flame) is still too short (previously max. currently prevents a broad introduction on the market . Several companies and institutes are working intensively on a solution in cooperation.

In new types of steam engines, instead of a reciprocating piston, a vane pump that has been converted into a rotary piston expansion machine is used. The water circulates in a closed circuit (heating by means of a flow heater - relaxation and thus cooling of the steam in the steam engine - liquefaction of the steam in a condenser - re-feeding the water with the help of a pump ). This design can be used as a small block-type thermal power station, especially in single-family houses .

Concrete applications

Steam buses have been around since 1826 . Over time, the nominal speed of the drives has increased continuously. Manufacturers of steam cars ( cars like the “ Stanley Steamer ” or White ) were important competitors to electric or gasoline-powered vehicles at the turn of the 19th and 20th centuries. Steam-powered trucks (see Sentinel ) were successfully built in the 1920s . In 1941, Henschel-Werke built the test locomotive 19 1001 for the use of steam engines in rail vehicles . However, there was no longer any series production. In England, the Midland Railway had already tried steam engines with locomotive 2299 between 1908 and 1919, with two steam engines working on the first and third axle and four steam engines on the middle one. In 1927 the Swiss SLM tested a high- pressure locomotive with a boiler pressure of 60 bar and steam engines. Here, however, the main problems were with the high-pressure boiler, and the increasing electrification of Swiss railways also reduced the need for steam locomotives .

In 1933 the brothers George D. and William J. Besler built a light steam engine into a modified Travel Air 2000 double-decker and carried out the first public flights on April 20, 1933. The double-acting two-cylinder V- compound steam engine made 150 bhp at 1625 revolutions per minute. Due to the possibility of direct reversal of the steam engine's direction of rotation, only 30 m runway length were required for the landing.

Web links

- IAV steam engine ( Memento from April 16, 2006 in the Internet Archive )

- Stanley Steamers

- Spilling Technologies GmbH *

- The Lübeck-Büchener Steam-Motor Locomotive

swell

- ^ The Besler Steam-Driven Airplane . flyingkettle.com. Retrieved June 14, 2009.

- ↑ With high pressure to heaven . The mirror. Retrieved June 14, 2009.