Flamecon

The Flamecon technology is a process developed by the international automotive supplier Leoni since around 2000 for the automated application of metallic structures such as conductor tracks to different carrier materials, such as B. plastic , metal oxides, wood and ceramics. Flamecon is used, among other things, in MID technology (Molded Interconnect Devices). One advantage lies in the chemical and mask-free production. In addition, the required tools can be mounted on software -controlled industrial robots , which results in a high degree of flexibility in production (batch size 1). In 2008 the technology was awarded the CNA Innovation Prize.

In 2017 it became known that there were disputes between Leoni and several former employees about the remuneration of the patents.

The procedure

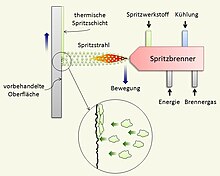

According to the publications, the surface is structured and metallized according to the structure using a thermal-kinetic process . Various structuring processes are used here, and the thermal-kinetic application process itself can take on the structuring function.

The metal to be applied is generally melted and sprayed onto the surface by pressure. The basic idea has long been known and is used e.g. B. used in flame spraying in coating technology. However, the surface is structured locally, for example by means of a laser , in order to ensure different levels of adhesion. Depending on the cross-section and metallurgical composition, the applied cables can be used for signal and power lines as well as for heating purposes. Due to the process, there is a certain porosity . This reduces the conductance compared to the solid material, but improves the properties in high-frequency applications (surface effect). The conductance loss is generally below 10%, which can either be compensated for by increasing the layer thickness or is not relevant in the case of only briefly high currents due to the better heat dissipation. Only with copper can there be an overall reduction of up to 50% IACS compared to solid material if the process parameters are unfavorable. As a result, this corresponds to the same conductivity class as the electroplated layer of a PCB or FPCB , but Flamecon can more easily create thicker layers and thus compensate for the loss. The reason for the increased IACS loss is that mechanical stresses, such as those caused by excessive particle speeds, have the same effect as oxides.

Targeted process management neither damages the plastic nor does metal deposits arise in undesired places.

classification

Procedure

- Metallization process

- PCB structuring

- Rapid prototyping

- Rapid Manufacturing / Digital Manufacturing

The process bridges the boundary between the classic MID processes such as TwoShotMolding, LDS and the like. a. and the wired or leadframe-bound metallization process.

Substrate materials: PS, ABS, PA, ... PEEK, ceramic, glass, metal oxide

Procedure and process window (exemplary)

- The substrate is roughened in a structured manner by laser, sandblasting, metal powder blasting or similar. In the simplest case, a felt pen works. Usually one works positively, i. That is, the structure applied in this way corresponds to the positive of the circuit diagram. Glazed ceramics usually have a negative structure. This creates a germ layer.

- A thermal-kinetic jet of metal powder, droplets, plasma, etc. is directed onto the substrate. This does not have to be focused on the structure, but can be applied globally. However, the application only takes place on the germ layer.

The two steps can be integrated into one another. The front of a particle beam can be sufficient as a nucleating agent. The patent describes the same.

commitment

Flamecon products are seen as a way of potentially replacing classic printed circuit boards (PCB such as FPCB), lead frames and cables. Since they integrate electrical structures, they can be used as antennas (Brose), heating elements e.g. B. from Dräxlmaier, sensors up to cameras (Magna), solenoid valves (Bosch), door switches or the like can be used as well as a carrier for LEDs such as in daytime running lights (Sylumis, Osram).

swell

- "Injection of conductor tracks on plastics" G. Reichinger Dr. K. Götz, Leoni AG, article published in VDI-Z 1 / 2–2005, Springer-Verlag

- Image material LEONI, test facility Makro-MID

- Flamecon at the IAA, LEONI stand

- Report on materialsgate

- EFFICIENCY IN 3-D

- Leoni Flamecon® - a new metallization process introduces itself

- Application video using the example of a Porsche rear light

- Dispensing and loading of Flamecon carriers, Häcker Automation .

- “Intelligence for traffic and logistics ”, http://www.drahtmagazin.de

Individual evidence

- ↑ Knuth GÖTZ, Gerhard Reichinger, Franz Zahradnik: Process for producing a molded part with an integrated conductor track and molded part . EP1517597 A2, March 23, 2005 ( google.com [accessed April 21, 2017]).

- ↑ a b Christian Fischer, Jörg Franke, Klaus Feldmann: Two Approaches for the Design of Molded Interconnect Devices (3D-MID) . In: Proceedings of the 6th CIRP-Sponsored International Conference on Digital Enterprise Technology . Springer, Berlin, Heidelberg, January 1, 2010, p. 67-78 , doi : 10.1007 / 978-3-642-10430-5_6 ( springer.com [accessed April 21, 2017]).

- ↑ a b "Intelligence for Transport and Logistics" . ( Drahtmagazin.de [accessed on April 6, 2018]).

- ↑ 3-D MID, manufacturing process: Flamecon , accessed on April 6, 2018.

- ^ CNA - Center for Transportations & Logistics Neuer Adler eV: Innovation Award - Prize Winners 2008 to 2014. Accessed on April 21, 2017 .

- ↑ Leoni: A breakdown series that does not stop. Retrieved April 12, 2018 .

- ↑ A method for producing a molded motor vehicle component with an integrated conductor track and molded motor vehicle component . ( google.com [accessed April 21, 2017]).

- ^ Di Su: Direct Structuring in Action. January 30, 2014, accessed April 21, 2017 .

- ↑ Götz, K., Reichinger, G., Ott, M., Süß-Wolf, R .: LEONI FLAMECON ® - structured metallization for higher performance . In: 3D-MID eV (Ed.): 6th international MID-Congress 2004 Erlangen . Erlangen 2004.

- ↑ A method for producing a molded motor vehicle component with an integrated conductor track and molded motor vehicle component . ( google.com [accessed April 21, 2017]).

- ↑ Marius Fedler: Alternatives to metallic lead frames . In: Kunststoff Institut Lüdenscheid (ed.): Euromold 2008 .

- ↑ VEHICLE PART FOR THE OUTSIDE AREA OF A MOTOR VEHICLE AND MOTOR VEHICLE . ( google.com [accessed April 21, 2017]).

- ↑ Vehicle camera housing with tolerance compensating connector . ( google.com [accessed April 21, 2017]).

- ↑ Juergen Graner, Martin Maier, Anselm Berg: Method for producing a solenoid valve . EP2644879 A1, October 2, 2013 ( google.com [accessed April 21, 2017]).

- ↑ Door handle unit for a vehicle . ( google.com [accessed April 21, 2017]).

- ↑ http://plasma-innovations.com/fileadmin/Loesungen/slider-loesungen.jpg

- ↑ LED module with a heat sink . ( google.com [accessed April 21, 2017]).