Knife head

A cutter head (also called milling head ) is a milling tool in which indexable inserts are used and is mainly suitable for face milling . A shoulder milling head is also suitable for face milling because the angle between the two outer cutting edges (the tool setting angle ) is 90 °. Otherwise it assumes values between 45 ° and 80 °.

construction

On the cylindrical or plate-shaped base body of a cutter head, depending on the design, there are larger recesses all around on the face and / or side surface, which are used for chip removal. In the inner surfaces of these large recesses there are even smaller recesses, corresponding to the working direction of rotation, into which exchangeable indexable inserts or displaceable holders for the same, so-called cassettes, are inserted and clamped or screwed. There is usually a slight increase in height and / or side difference between the individual indexable inserts, so that all the inserts on the cutter head can always remove material simultaneously and evenly. In the case of a design with cassettes, a correspondingly adjustable height and / or lateral adjustment of the individual indexable inserts to one another or to the base body of the cutter head is also possible. To vary the cutting edge geometry , various inserts can be clamped under the indexable inserts.

Subdivision

Depending on the cutter geometry, a distinction is made between different types of construction for the cutter heads. Common types of cutter heads are face cutter heads, corner cutter heads, form cutters and so-called hedgehog cutters. However, all other types of milling cutters and drills based on the construction principle of a cutter head are also being used more and more frequently. A further distinction is made between different divisions according to the number of “knives” that can be used and according to the need for chip evacuation space, depending on the requirements for short or long-chipping material. Uneven pitches are common, as this has an advantage in terms of vibration sensitivity. However, divisions are also used regularly.

advantages

The decisive advantages of the cutter heads compared to conventional one-piece milling cutters are the standardized indexable inserts and the very high cutting performance that can be achieved with the appropriate cutting materials .

Cutter heads offer great advantages through:

- The indexable insert can be changed very quickly, even on the clamped tool.

- Time savings by maintaining the tool geometry and cutting data when changing the indexable insert.

- Considerable reduction in operating costs thanks to the ability to restore usability as quickly as possible after the service life has expired due to wear or damage to individual cutting edges / indexable inserts.

- Possibility to switch to specialized indexable inserts for different materials and processes.

- Considerable reduction in operating costs through the optimization of cutting performance that is possible.

- Reduction of the milling tools required because of the universal applicability.

- Significant reduction in operating costs thanks to unlimited reusability compared to conventional milling tools.

disadvantage

The acquisition costs are many times higher compared to a simple milling cutter of the same design. There are only limited repair and reworking options for damaged cutter heads - these are also more expensive in line with the acquisition costs.

photos

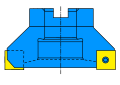

Plan cutter head in section

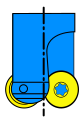

Older cutter head with cutting steels instead of indexable inserts made of carbide