Cast iron with vermicular graphite

|

|

DIN EN 16079 |

|---|---|

| Area | Materials |

| title | Foundry - cast iron with vermicular graphite |

| Latest edition | 2012-02 |

| ISO | 16112 |

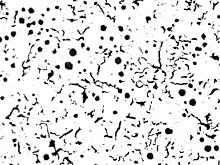

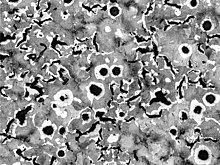

Cast iron with vermicular graphite, also called worm graphite (abbreviated GJV ), is a cast iron whose graphite is predominantly in vermicular form (vermiculus = worm). In English usage the material is called Compacted Graphite Iron (abbreviated CGI ).

General

Cast iron with vermicular graphite has been used since the 1930s; it is characterized above all by a favorable combination of tensile strength , toughness , damping , thermal conductivity, thermal shock resistance, machinability and castability. For these reasons, it is used to a large extent in thermally stressed components of internal combustion engines , but other areas of application are also known.

Classification

Cast iron with vermicular graphite is standardized according to EN 16079, which is also available as a DIN standard , and ISO 16112.

There is also a generally recognized VDG leaflet in Germany. The material types are then classified according to the minimum tensile strength of 300, 350, 400, 450 and 500 N / mm². GJV-300 (300 N / mm²), which is the only pure ferritic grade, is used most frequently.

properties

In general, cast iron with vermicular graphite is used if at least 80% are vermicular, the rest may be spherical but not lamellar. However, higher nodular graphite proportions are absolutely permissible. The mechanical properties of cast iron with vermicular graphite lie between the properties of lamellar and spheroidal graphite .

strength

Cast iron with vermicular graphite has a pronounced 0.2% yield strength . The strength is on average at least 50% higher than that of cast iron with lamellar graphite, but it depends on both the wall thickness and the silicon content.

Machinability

See machinability of cast iron

Properties at elevated temperatures

Important areas of application for cast iron with vermicular graphite are components that are stressed by increased temperatures and, above all, by temperature changes. These fail, for example, due to internal and external oxidation , waxing, cracks and / or warpage . Cast iron with vermicular graphite represents a favorable compromise between contradicting requirements. The fatigue strength and its ductility give the material almost the same crack resistance as cast iron with spheroidal graphite , while it warps less thanks to the lower modulus of elasticity and higher thermal conductivity .

use

Compacted graphite cast iron is used in several areas. The main area of application is diesel engine construction : There it is used in ships , large engines, yachts, commercial vehicles and heavily motorized passenger cars . The weight savings compared to gray cast iron can be up to 15% through thinner wall thicknesses.