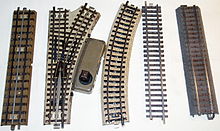

Track systems of the H0 gauge

Track systems for the H0 gauge with 16.5 mm gauge (or for the previous 16.0 mm gauge) have been produced since the 1920s. In 1922, the Nuremberg company Bing first presented a table track with a clockwork drive; An electric version followed two years later.

The slope body and rails were initially pressed from sheet metal, followed in 1935 by Trix Express with a slope body made of Bakelite and three electrically separated rails. In the years after the Second World War, threshold strips made of black insulating cardboard were introduced. From the mid-1960s, threshold strips made of plastics appeared. At the same time, the first flexible tracks were offered, which can be laid in any shape regardless of the track geometry of the manufacturer.

In the case of the H0 gauge, three electrical track systems can be distinguished: the two-rail two-rail track system, the three-rail two-rail track system and the three-rail three-rail track system. There were also two-rail track systems for the clockwork railways without electrical insulation of the rails.

The trend today is towards the prototypical two-rail, two-rail system. At the same time, however, nostalgia systems are increasingly being designed and exhibited with the old track systems, vehicles and accessories.

Two-rail, two-rail track system

Each rail forms an electrical potential . The advantage of the system is the international standardization with a large selection of track assortments and vehicle models from many manufacturers worldwide. One disadvantage is that electrical functions, such as a track occupancy message, cannot take place via the short-circuit of the two rails through the wheelset on them, as in the prototype. Reversing loops and track triangles require special circuit measures to avoid short circuits.

Current track manufacturers (selection): Atlas , Bemo , Fleischmann , Hornby , Kleinbahn , Piko , Roco , Shinohara, Tillig and Trix -H0.

The rail profile height is defined in the NEM standards of European model railways. For the H0 gauge, NEM 120 recommends a rail profile height of 2.0 or 2.5 mm. With the two-rail track systems, smaller rail profile heights are now also offered in order to be able to build the track systems to scale. These variants are designated with code xx, whereby for example code 70 describes a rail profile height of 0.070 inches , specified in RP 15.1 of the NMRA . The use of low rail profiles requires the use of vehicles with reduced wheel flanges.

The two-rail, two-conductor track system uses direct current for analogue driving.

Three-rail two-rail track system

In this track system, the two running rails are electrically connected to one another via the embankment body or via the sleepers, and the middle rail is electrically insulated for this purpose. This track system has its origins in the first electric tinplate railways of the large lanes that had metal sleepers. In 1924, the Bing company presented the first electric table track with this track system and a 16.0 mm gauge; this was followed by Märklin 00 in 1935 and Hornby Dublo (3-rail) in 1938 . The production of the Bing range was stopped in 1932, but was taken over by the Bub company for a few years. Hornby switched to the two-rail two-rail system (2-rail) in 1959.

Middle rails are usually not used in the prototype. In the greater London area , the underground railways and many suburban railways are equipped with conductor rails in the middle and side positions.

The track assortments of the three manufacturers mentioned initially had embankment bodies made of sheet metal and a continuous central rail that was insulated with cardboard disks. The two running rails formed the mass , the middle rail the phase . With this track system, all track figures are possible without any special circuitry.

From the mid-1950s, Märklin's eye-catching middle rail was replaced by a comb-shaped ladder hidden under the sleepers, of which only the so-called point contacts are visible. This variant is also known as the Puko track. At switches and crossings, the middle rail or the point contacts must protrude sufficiently high above the runways to prevent the middle slider from coming into contact with the runways.

If both runways have the same potential, it is sufficient that only one side of the vehicle is in contact. Therefore, track occupation circuits can be set up in a prototypical manner using short sections with rails that are insulated on one side.

Märklin is currently the only full-range manufacturer for this track system. Märklin thus provides the standardization for the design of the vehicles as well as the tracks and points. The two wheel disks of a wheel set are connected to one another in an electrically conductive manner.

Märklin locomotives normally use (a regulated transformer is used) alternating current for driving. Since single-phase series motors are used, they can also be operated with direct current. At Hornby Dublo, direct current was already used in 1938. The locomotives from Bing could be driven with alternating or direct current (all-current motor with field coil).

There are special retrofit kits from some smaller manufacturers with which simple two-rail tracks can be converted to single-rail tracks. With the appropriate effort, it is of course also possible to install center conductors yourself.

Rolling stock and accessories, however, are offered by many other manufacturers. Wagons with insulated wheel sets for the two-rail, two-rail system can be used on Märklin tracks with almost no problems; derailments can only occur in the heart of older points and crossings due to the different distance between the rear surfaces of the wheel sets. The lighting equipment does not work on three-rail tracks without being converted to a center grinder. Locomotives can be converted with reasonable effort, provided they have enough space for the center grinder and are to be digitized.

The use of rolling stock of the three-rail, two-rail system on two-rail, two-rail tracks is possible on wagons after the wheel sets have been replaced, since the wheel disks of the wheel sets must be electrically isolated from one another. The conversion of locomotives, especially steam locomotives, involves a relatively high level of effort.

Three-rail, three-conductor track system

→ Main article: Three-wire track system

By using Bakelite for the embankment body, Trix Express was able to present a track system with three electrically isolated rails in 1935, which enables independent two-train operation on one track. In this system, the middle rail forms the return conductor; both runways carry different driving current poles. This allows two locomotives to run on the same track and be controlled independently of each other.

The only full-range manufacturer of this system from 1935 to the end of the 1990s was the Nuremberg company Trix under the brand name Trix Express . Trix had this system protected by patents. In England, the Trix company there built its own range for the British market under the brand name Trix Twin Railways .

In connection with an overhead line , this track system even enabled independent three-train operation. Electric locomotives with switched on pantographs receive the voltage via the overhead line, the return line is provided via the center conductor. In this case, the wheel grinders are switched off (or even removed), the electric locomotives can be placed on the track in any orientation and drive through turning loops and track triangles without restriction. For other locomotives (without active pantographs) the circuit used is determined by the alignment of the locomotives and the external grinder.

From 1935 until production was discontinued, the Trix Express vehicles had relatively high wheel flanges and a different rear surface distance. The dimensions of the guide and groove widths in the core areas of switches and crossings and the rail profile heights were matched to this. Trix could not bring itself to modernize these dimensions with the three-rail, three-wire system. Trix tried from 1964 under the product name Trix International with a two-rail, two-wire range according to the internationally standardized specifications to get in touch with the development.

The historic Trix Express system is now gaining attention again. Nostalgic railways are increasingly being built with the original track system and suitable vehicles and presented at exhibitions.

The Trix Express locomotives initially had motors with field windings (all-current motors) and were mostly operated with alternating current. A shift drum made it possible to change the direction of travel in conjunction with a special speed controller. From 1953 the locomotives were converted to direct current operation by permanent field motors.

Overhead line operation

In addition, an overhead line can be used with all three track systems to independently operate another vehicle on the same track - the introduction of digital technology in the mid-1980s made an overhead line obsolete, so that today it usually no longer has an electrical function and is often only for decorative purposes serves.

Terms

For a long time, the terms two-conductor direct current track system and central conductor alternating current track system were correct for the systems that were most widespread at this point. However, with the emergence of digital systems in the mid-1980s, these terms are no longer up to date.

Central conductor alternating current track system

The system-related mechanical changeover switch in the locomotives for the central conductor alternating current track has meanwhile been replaced by electronic changeover switches, which today are pure digital decoders or combined digital, function and sound decoders. On central conductor AC tracks, more and more people are driving in digital mode. This means that there is no longer a sinusoidal alternating voltage , but a square-wave voltage on the tracks, which transmits the digital commands in addition to the power.

Two-wire direct current track system

Gradual digitization has also been taking place in the two-wire DC track system for years. However, since the system never required mechanical changeover switches, digital technology spread only slowly for a long time. It was only with the advent of combined digital, function and sound decoders in the mid-2000s that there was a trend reversal towards digital operation in two-wire direct current.