Hydraulic switch

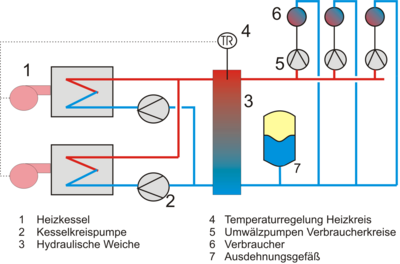

A hydraulic switch is mainly used in heating systems in order to hydraulically decouple the heating circuit (or circuit heat generator or circuit cold generator) and the consumer circuit from each other. As soon as other volume flows have to be realized in the consumer circuit than required by the boiler circuit, it is advisable to provide separate pumps in the respective circuits. A hydraulic separator is necessary so that these pumps with their different pressure and volume flow parameters do not influence each other.

If the heating and consumer circuit are not decoupled, the following problems can occur:

- Under certain operating conditions, heating pumps can be operated in an unfavorable range of their characteristic field . This results in higher power consumption, noise, the onset of cavitation and a shorter service life.

- Individual temperature control of the consumer circuits is difficult, as the pressures in the flow and return headers are subject to greater fluctuations.

Layout and function

In the simplest case, a hydraulic separator is a pipe between the heating circuit and the consumer circuit (or consumer circuits), which connects the supply and return flows of both systems with one another with little flow resistance, i.e. short-circuits. Directly at the switch, all differential pressures between supply and return lines are approximately zero (hydraulic zero point).

In practice, this is achieved using a vertically arranged pipeline with a large internal diameter. The volume flow density (flow velocity) occurring in it is relatively small. In the switch, a temperature stratification is formed due to the difference in density between warm and cold liquid. The warm feed water is in the upper area and the colder return water is in the lower area.

The circulated volume flows in the heating and consumer circuit depend on the respective operating status and are therefore usually different. As a result, parts of the flow and return water mix in the switch. If the current volume flow of the circulation pumps in the heating circuit is greater, then a proportion of the warm flow of the heating circuit is added to the return water from the consumer circuit. If, on the other hand, a larger volume flow is circulated in the consumer circuits, the flow temperature to the consumers is reduced by adding the colder return water (see Richmann's mixing rule ).

In order to be able to maintain a specified flow temperature independently of the individual volume flows, the volume flows of the heating circuit pumps are regulated in such a way that the mixing in the hydraulic separator is kept as low as possible. As a result, the output of the heat generator adapts. This is particularly important when using a hydraulic separator in connection with a condensing boiler , since a low return temperature in the boiler circuit is the prerequisite for efficient use of the heat from the combustion gases.

Since the density of the water changes depending on the temperature level in the system, the volume in the switch must be taken into account when dimensioning pressure maintenance systems (e.g. diaphragm expansion vessels ).

Distribution switch

The distributor switch is a combination of distribution and hydraulic switch. This offers individual access and exit points to the temperature layers created in the switch, so that heat generators and consumers can feed in or remove from them the appropriate temperature layers.

literature

- Norbert Schäfer: District heating supply. House system technology in theory and practice. Springer Verlag Berlin Heidelberg, Berlin Heidelberg 2001, ISBN 978-3-540-67755-0 .

- Hans Roos: Hydraulics of the water heating. 5th edition, Oldenbourg Verlag, Munich 2002, ISBN 3-486-26529-6 .

Web links

- Hydraulic switch (accessed January 15, 2016)

- Balancing load and power (accessed January 15, 2016)