Hydraulics

Hydraulic ( Greek nominalized adjective υδραυλική [τέχνη] hydrauliké [téchne] "the hydraulic [Technology]" by ancient Greek ὕδωρ HYDOR "the water " and αὐλός AULOS "the tube") is the science of flow behavior of liquids . In technology , this is understood to mean the use of liquids for signal , force and energy transmission and for supplying lubricants .

In a narrower sense, the term only describes systems that use pressure differences for signal, force and energy transmission. In a broader sense, also systems that use thermal or kinetic energy (e.g. heating systems and hydropower plants ).

historical development

The Englishman Joseph Bramah is considered to be the founder of technical hydraulics . In 1795 he developed a hydromechanical machine operated with pressurized water, which worked according to the hydrostatic law of Blaise Pascal and increased the applied force 2034 times. In 1851 William G. Armstrong developed the weight accumulator , a storage device that could be used to generate large volume flows . The London Hydraulic Power Company commissioned a central pressurized water supply for several hydraulic systems in 1882.

1905 is considered to be the beginning of oil hydraulics, when Harvey D. Williams and Reynold Janney first used mineral oil as the transmission medium for a hydrostatic transmission in axial piston design with a swash plate, which they used for displacements at a maximum pressure of 40 bar. Hele-Shaw developed the first useful radial piston machine in 1910 . In 1929 the engineers Hans Thoma and Heinrich Kosel received a patent for an axial piston machine in bent axis design . Harry Vickers developed the first power steering (around 1925), and he developed the first pilot operated pressure valve in 1936. Jean Mercier built the first hydropneumatic pressure accumulators on a large scale in 1950. Works by John F. Blackburn , Shih-Ying Lee and Jesse Lowen Shearer , which appeared in the USA in 1958, were important for the development of servo hydraulics .

Hydraulics for power transmission

Hydraulic is in the art a Transmission - mechanical alternatively, electrical and pneumatic transmissions. It is used to transfer power, energy or force / torque from the machine (pump) to the engine (piston or hydraulic motor), the performance parameters being adapted to the requirements of the engine. The hydraulics transmit the power through the hydraulic fluid , usually special mineral oil , but increasingly also through environmentally friendly fluids such as water or special carboxylic acid esters or glycols . The transmitted power results from the factors pressure and volume flow . A distinction must be made between:

- hydrodynamic drives work with a pump and a drive turbine. The speed and torque conversion takes place via the kinetic energy of the liquid.

- On the primary side, hydrostatic drives convert the mechanical power of the prime mover ( electric motor ; diesel engine ) into hydraulic power using a pump ( machine ). This power is converted to consumers (combustion engine) back into mechanical power and indeed in hydraulic cylinders in a linear motion or hydraulic motors in a rotational movement. Hydrostatic drives are more efficient than other types of gearbox if the speed on the output side has to be continuously adjustable.

By introducing pressurized liquid into the cylinder , the pistons and piston rods located therein are set in linear motion, which is used for work processes and for driving machines. Rotating drives can also be implemented using fluid pressure, for example with a hydraulic motor.

Hydraulic systems are fundamentally similar to pneumatic drives , in which compressed air is used to transmit power and signals, but have different properties. In oil hydraulics, for example, a fluid circuit is always required (there and back), while in pneumatics the exhaust air is blown off into the environment - usually via a silencer . It is only with the water hydraulics that there are occasionally no circuits. Compared to pneumatics, hydraulics has the advantage that significantly higher forces can be transmitted and very uniform and exact travel movements are possible, since the compression of the hydraulic fluid is so low that it hardly has a negative effect on technical applications.

The combination of hydraulic elements with electrical components for control is called electrohydraulics .

advantages

The hydraulic system owes its widespread use in many branches of industry to the following advantages:

- the broken-up design, i.e. the flexible connection between input and output and good structural adaptation to space requirements. The connection between the motor and the pump is made up of pipes and hoses , which can largely be laid freely. In the case of mechanical drives, on the other hand, it is necessary to establish a direct connection between the engine and transmission and further to the differential via, for example, a cardan shaft , Hardy disk , flexible disk or a chain. Therefore, the position of the transmission is largely determined by the position of the motor.

- Modern, splash-free clean break quick couplings enable the consumer and pump to be disconnected safely and cleanly . There is little dirt and air entering the hydraulic system.

- Stepless speed setting of the output within very wide limits, simple reversal of the direction of movement

- Generation of linear output movements with simple technical components with very high levels of efficiency

- easy generation of very large forces and torques

- safe and fast-acting overload protection through pressure relief valve

- high power density, that is, comparatively small components for high performance, especially when compared to electric motors

- Realization of parallel working translatory or rotary output elements (hydraulic cylinders or hydraulic motors) with a primary part (pump) in a common system, resulting in the effect of a differential without further effort

- long service life because the fluid is self-lubricating and can serve as a cooling medium

- simple control concepts for optimal utilization of the drive motor with strongly varying performance requirements of the driven machine

- high positioning accuracy

- uniform movements due to the low compressibility of the hydraulic fluid

- Standardization through the use of standardized components, connection dimensions, installation spaces, etc.

- simple display of the load by pressure gauges

- low inductance of the hydraulic motors and cylinders

- Starting from standstill at full load

- fast (but slower than pneumatics for the same working pressure), sensitive, uniform and continuously adjustable cylinder and motor speeds.

- Hydraulic oils reduce friction in the actuators.

- Corrosion protection through hydraulic fluid (except water)

- no electrical stray field of the drives

disadvantage

- The disadvantage of hydraulic drives is the compressibility of the fluid, which leads to compression under pressure. This may result in pressure and movement oscillations. This problem only affects drives with high demands on the uniformity of the speed with heavily changing loads, for example feed drives on machine tools. Flexible couplings have to be used to counteract this, which increases costs.

- high demands on the purity of the hydraulic fluid

- Switching noises of the valves

- Risk of leaks, leakage of oil

- Temperature dependency of hydraulic oils ( viscosity and energy loss due to internal friction increase with falling temperatures)

- Flow losses that are converted into heat and heat up the system (energy loss)

- Vibration tendency due to pressure surges and the associated noise development

Applications

Hydraulic cylinders with linear movement are used to lift loads in forklifts , excavators , elevators , vehicle cranes , etc.

Mobile machines such as construction machinery or agricultural machinery are often equipped with hydraulic drives.

Vehicles are often driven with hydraulic gears or fluid converters, for example with so-called bent axis and swash plate machines, with which high power can be transmitted. With hydraulic transmissions, the power transmission of an engine operating at a fixed speed can be flexibly adapted to the operating conditions, for example in automatic transmissions and hydraulic drives in diesel locomotives .

Further typical application examples are:

- Hydraulic screwdrivers and bolt tensioners for bolt tensioning

- Elevators with low lifting heights but high payloads

- Motor vehicles and muscle-powered two- and three-wheelers of various types: brakes ( brake fluid , also on bicycles), automated gearboxes , power steering , chassis control, convertible tops

- Combustion engine : camshaft adjustment, valve actuation, actuation of injection units

- Airplane : complete control of the wing flaps (designed during the Second World War ) as well as retraction and extension of the landing gear

- Rail brakes in the marshalling yard

- Agriculture in tractors to lift, drive or control implements

- Vehicles : Vehicles are lifted with the help of hydraulic lifting platforms

- Excavator : hydraulic drive of all work equipment including slewing gear and chassis

-

Mobile cranes : hydraulic drive of the telescopic masts, hoist and winch

gear , slewing gear, support, steering and, in some cases, travel drive for industrial trucks,

for example forklifts: all movements including travel drive and steering - Climbing cranes and advancing equipment are hydraulically lifted and moved.

- Tractors : Power lift package with position controller for the implements; Steering hydraulics

- Forestry machinery : Hydrostatic travel and work drives

- Commercial vehicles : tilting hydraulics; Tail lifts; Power steering (power steering); Clutch and brake actuation; hydrostatic drive on the front axle ( MAN )

- Tanks and frigates : Hydrostatic superimposed steering, servohydraulic directional drives for the main weapon or for the turrets

- Machine tools : main and auxiliary movements on presses, shears and folding machines; Feed movement on grinding machines, operating functions such as tool changers, workpiece and tool clamping and axis clamping on all cutting machine tools. The force can be multiplied by pressure transducers .

- Hand tools that achieve particularly high forces: for cutting wire rope, pressing rope clamps, water pipe fittings, electrical equipment

- Metallurgy : drives on electric and walking beam furnaces; Continuous casting plants; Charging and cooling beds

- Rolling mills : roll gap regulation (regulation of the thickness of the rolled material by means of so-called hydraulic adjusting cylinders); all auxiliary movements for feeding the rolling stock; Straightening and shear drives

- Actuator : Electrohydraulic control of fluids ( pressure , flow ) in process engineering , power plants , pipelines

- Mining : Cylinders in walking support , hydrostatic drives in mining machines and tunneling machines

- general: hydraulic ram for moving heavy loads e.g. B. in the construction industry for the advancement and installation of bridge girders and other heavy prefabricated parts, for heavy load transports or as a rescue device for THW and fire brigade

- Automotive supplier: For deep-drawing engine hoods, fenders or other body parts

- Bicycle construction : hydroforming of aluminum tube as part of the frame, central expansion of the handlebar tube

- Fire brigade : The fire brigade uses the hydraulic rescue set , which consists of a rescue spreader, rescue scissors and rescue cylinder, to rescue people from deformed vehicles.

- In high-speed machines (such as turbines), hydraulic pumps are used to supply the bearings with lubricants and coolants , which convey the liquids to the supply point via hydraulic lines. The oil flows back to the pump via separate pressure lines.

- Catapult drives in roller coasters : hydraulic oil is pumped into storage cylinders filled with nitrogen, the nitrogen is compressed. After being released for launch, the pressurized oil is fed into many small hydraulic motors that drive a cable winch via a gearbox. The train hooked into the rope is accelerated like a catapult.

Hydraulic hand press

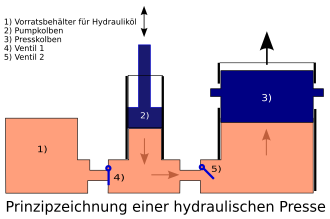

With the hydraulic press , a large force can be achieved with little physical effort. By manually pumping on the pump piston (2) of a car jack, a load weighing tons can be lifted on the press piston (3).

Functional description: If the pump piston (2) is pressed down, the valve (4) closes and the valve (5) opens, so that hydraulic oil flows into the press cylinder. The plunger (3) rises. If the pump piston is moved upwards, the valve (4) opens and the valve (5) closes. This allows hydraulic oil to flow in from the reservoir (1). If a force of 100 N acts on the pump piston with an area of 0.5 cm² (corresponds to an applied mass of about 10 kg), this results in a pressure of

This static pressure also acts in the press cylinder. If the plunger has an area of 40 cm², a force of

- ,

with which you can lift about 800 kg. In order to push the plunger upwards by one centimeter against this load, a volume of 40 cm³ must be moved. This requires several pump strokes of a total of 80 cm. The hydraulic or pressure energy is

- .

This energy is equal to the work that is expended on the pump piston and performed by the plunger:

- Schematic representation and circuit diagram of a simple hydraulic system with one cylinder

Circuit symbols and circuits

A circuit diagram is the plan of a hydraulic system. The components are represented by standardized symbols . These plans are part of the documentation required for every system , and are particularly important for creating and maintaining the system. The list of symbols (fluid technology) contains an extensive list of symbols for hydraulics and pneumatics, such as symbols for accumulators, filters, pumps and compressors, cylinders and valves.

Circuit diagrams can be created individually, company-specific or according to standards (DIN ISO 1219). You can use parts such as B. represent working and control circuits, the steps of the work flow, the components of the circuit with their identification as well as the lines and connections. The spatial arrangement of the components is usually not taken into account.

A symbol only shows the function of a component or device, it says nothing about the structural design and installation position of the hydraulic components. Symbols are shown in one color and are normally shown inactive, de-energized or in their initial position. Relationships such as the electro-hydraulic analogy can be used for modeling .

See also

literature

- Horst Beer: 100 years of development and use of hydraulics in eastern Germany. A contribution to the history of technology and industry. GNN-Verlag, Schkeuditz 2008, ISBN 978-3-89819-240-8 .

- H. Exner, R. Freitag, H. Geis, R. Lang. J. Oppolzer: The hydraulic trainer. Volume 1: Hydraulics - Basics and Components . 3rd revised edition. Published by Bosch Rexroth AG. Mannesmann Rexroth, Lohr 2002, ISBN 3-933698-30-8 .

- D. Merkle, K. Rupp, D. Scholz: Electrohydraulics. Elementary level. Springer, Berlin a. a. 1997, ISBN 3-540-62087-7 .

- D. Merkle, B. Schrader, M. Thomes: Hydraulics. Elementary level. Springer, Heidelberg a. a. 1997, ISBN 3-540-62091-5 .

- Dieter Will (Ed.): Hydraulics. Basics, components, circuits. 3rd revised and supplemented edition. Springer-Verlag, Berlin a. a. 2007, ISBN 978-3-540-34322-6 .

- Helmut Wetteborn: Hydraulic line technology: a practical manual. 1st edition, Hansa-Flex, Bremen 2008, ISBN 978-3-88808-703-5 .

Web links

Individual evidence

- ↑ a b Hydraulics and lubrication for turbines weighing tons ( Memento from June 30, 2015 in the Internet Archive )

- ↑ a b c d e f g Wolfgang Backé : Fundamentals of Oil Hydraulics, Institute for Hydraulic and Pneumatic Drives and Controls at RWTH Aachen University, 1974, p. 2f

- ↑ Matthies, Renius: Introduction to Oil Hydraulics , p. 20

- ↑ Spruce Goose Rules: How the Hughes H-4 Hercules Set Aviation History (With Just 1 Flight) , The National Interest, April 6, 2019

- ↑ Coastersandmore.de - roller coaster magazine: roller coaster types from A for Accelerator to Z for Zac Spin: drives. Retrieved July 4, 2020 .