silencer

A silencer is a device for reducing noise emissions .

The most common form of a silencer, however, is that in almost every motor vehicle with the aim of significantly reducing engine and exhaust noise. The use in duct systems and pipelines of air duct systems in building technology is just as widespread . Here z. B. used in ventilation lines so-called telephony silencers and so-called scenes in channels.

There are different types of silencers that reduce the sound power generated due to different mechanisms of action . Usually absorption or interference dampers are used.

Silencers are also known from weapons from action films and television series.

Mufflers in internal combustion engines

The muffler in an exhaust system are designed to reduce noise of the mouth of the exhaust system of motor vehicles and exhaust system is called. They are also connected downstream of catalytic converters, which act as silencers and if necessary .

In addition to standard silencers, numerous sports silencers are also available for passenger cars and motorcycles, which are used for vehicle tuning . As a rule, these mufflers offer a sportier exhaust sound and higher quality material, quality and appearance. In most cases they are offered with an EC type approval and are therefore free of registration. The assembly is carried out using the original mounting points on the vehicle.

Reflection silencer

The muffler contains several (typically four) chambers in order to use the principle of sound reflection . When multiple passes through the interiors there is an averaging of the sound pressure amplitude, resulting in a reduction of the sound pressure peaks result. Reflections are generated in a silencer by baffles, cross-section expansions and constrictions. However, depending on the design, the exhaust back pressure increases. This is even desirable in two-stroke gasoline engines to reduce scavenging losses, so that removing the damper for the purpose of sound tuning can impair engine performance and consumption. Mainly the low frequencies are dampened by reflection in the silencer .

Absorption silencer

An absorption sound absorber contains porous material, usually rock wool , glass wool or fiberglass , which partially absorbs the sound energy, i.e. converts it into heat . The effect of sound absorption is enhanced by the multiple reflection. It is possible to reduce exhaust noise by 50 dB (A), which corresponds to a reduction in sound pressure by a factor of 300. It is mainly the higher frequencies that are dampened in the silencer by absorption .

As a rule, both processes are combined in one exhaust system. Either as a separate silencer (middle and rear silencer) or in a single combined silencer. This way you can cover the broadest possible frequency spectrum.

Active counter silencers

New silencers that work with counter -noise are technically capable of lowering the noise from cars by up to 20 dB (A) compared to conventional silencers. A noise reduction of 20 dB (A) is perceived as a reduction of the noise by a quarter. By using this technology, even heavy trucks and powerful motorcycles can reach the level of current, quiet cars.

The electronic counter silencers are smaller and lighter than classic silencers. The counter pressure, which has been reduced by around 35%, can either increase performance or reduce fuel consumption and thus CO 2 emissions.

Condensation

Exhaust systems and especially the mufflers of internal combustion engines that are not operated continuously - such as. B. Motor vehicles on short journeys - are particularly prone to corrosion . Water from the combustion process condenses on the walls of the exhaust system, which are still cold when the engine is started, in which aggressive residues (e.g. sulfur ) are dissolved. Since the flow speed of the exhaust gas is reduced in the silencers, the aggressive condensate collects there and leads to the destruction of the silencer from the inside out. Especially in short-distance operation, the silencers do not get warm enough to allow the condensate to evaporate quickly. The use of stainless steel has significantly increased the resistance of the silencers to corrosive attacks. These steels, which contain chromium and in some cases nickel and molybdenum, have been used in silencers, especially in the automotive industry, since the early 1990s. They allow designers to guarantee against rust through for several years.

Silencers in ventilation systems

The main purpose of the silencers is to reduce the noise transmitted by the air flow, or to reduce the transmission of noise between rooms such as B. to prevent between movie theaters.

Fans are used in ventilation systems. Fans are intense sources of noise. The sound emitted by fans reaches the rooms via the often widely branched system of air lines or is emitted to the outside via exhaust air openings. In order to achieve the goals of noise protection inside and outside the building, the installation of sound absorbers is in most cases unavoidable. In addition to the “main silencer”, which is preferably located near the fan, it is often necessary, depending on the sound insulation requirements, to install additional silencers in the air line, for example to reduce the flow noise of components in the air line.

When ventilating engine rooms, machines are often the dominant source of noise. Here, silencers are used to provide the necessary cooling air for z. B. supply or discharge refrigeration units without the machine noise causing nuisance in the area.

Silencers are also required when sound from noise-filled rooms penetrates air ducts and can be emitted at another point. The transmission of sound via this path is also referred to as "telephony" and the silencers used to reduce the sound as "telephony silencers".

Mode of action

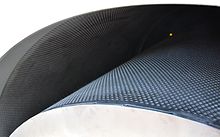

Basically, sound absorbers have the task of reducing the airborne sound propagating through the duct system without providing any significant resistance to the flowing medium. The medium flows through channels that are designed to be as aerodynamic as possible and lined with sound-absorbing material. Mineral wool is predominantly used as the absorption material, the sides of which facing the air flow are protected against abrasion with a sound-permeable material, usually fiberglass fabric. In order to achieve a high damping effect, channels with a large cross-section are divided into narrow single-line channels that absorb absorption on both sides by arranging block-shaped absorbing elements, so-called scenes, at a distance from one another. The scenes form narrow shafts through which the medium flows.

Silencers with a round cross-section are also known as pipe silencers. For large cross-sections, the cross-sectional subdivision is achieved by the central arrangement of a so-called core filled with absorption material. Pipe silencers with ring-shaped splitters are also used.

Technical parameters

The technical parameters of the silencers - insertion loss, flow noise and total pressure loss - are determined by laboratory measurements in accordance with DIN EN ISO 7235. A standardized test bench is located at the Fraunhofer Institute for Building Physics in Stuttgart. Several manufacturers have joined the RAL Gütegemeinschaft Kulissenschallverbindungen e. V. united with the aim of having the product data of the silencers voluntarily checked and monitored by this independent test center on the basis of uniform quality and test provisions.

Design of the silencer for the specific application

The determination of the dimensions and the suitable type is done arithmetically, specifying the volume flow, the damping values and the permissible pressure loss. Many manufacturers provide free dimensioning software based on measured values for the design.

Types of silencers

Silencers must be matched as well as possible to the frequency spectrum of the sound source. Therefore, different types of silencers are used in ventilation technology:

Absorption silencer

The vibrations of the air molecules caused by the sound are slowed down in the porous absorption material (often mineral wool). In this way, the sound energy is ultimately converted into thermal energy. Silencers that work according to the pure absorption principle have excellent damping values at medium and high frequencies. Absorption silencers are ineffective for low frequencies since the absorber layers have to be made very thick, which results in very voluminous silencers.

Resonance silencer

The term "resonance silencer" stands for different construction principles which have in common that a spring, usually in the form of an air volume, is excited to resonate in connection with an acoustic mass. The acoustic mass can either be a plate (plate resonator) that closes off the air space or a co-oscillating air mass (perforated plate resonator, Helmholtz resonator). Energy is withdrawn from the sound field in the area of the resonance frequency. This effect is essentially limited to low frequencies and to a certain frequency, but can be effective over a broader frequency range through the series connection of differently tuned resonators and / or additional damping with absorber material. Resonance silencers are often combined with absorption silencers.

Chamber absorption silencer

So-called chamber absorption baffles are often used in air conditioning. With this type, the absorber (mineral wool) is covered on one side by a thin solid sheet. Inside the backdrop, the backdrop frame forms a chamber in conjunction with the cover plate and a bulkhead plate. The mass of the solid sheet and the chamber volume work together to create a resonance effect, while the uncovered backdrop surface acts as an absorber. This type of silencer has a broadband attenuation spectrum with improved attenuation at low frequencies.

Active silencers

In addition to the silencers of the type described, there are silencers with an electroacoustic operating principle ( anti- noise ) or electronically amplified resonators. Because of the auxiliary energy required, these silencers are known as "active silencers". The main advantage of this technology is that high attenuation values can be achieved over a short length without additional pressure loss. The disadvantage is that the effectiveness is limited to relatively small dimensions of the air line and to low frequencies.

Silencers on weapons

Small arms can also be equipped with silencers. In general, the muffler case is either the provided with an external thread muzzle screwed or by a coupling to a suitably equipped muzzle article - such as a muzzle brake or a glow damper fitted and fixed -. Much less often, the silencer can also be used, e.g. B. be designed as an integral part of the weapon in the MP5 SD or the AWS .

The muffler only reduces the noise emitted by the gases that are under high pressure and expand in an explosive manner, flowing out of the muzzle when the shot is fired. The mechanical noises of any existing automatic reloading system and the loud blast of projectiles that are fired at supersonic speed ( supersonic ammunition ) remain unaffected. The bullet crack, which also occurs when using a silencer, can, however, be avoided by using subsonic ammunition (projectiles that fly just below the speed of sound).

literature

- Peter Gerigk, Detlev Bruhn, Dietmar Danner: Automotive engineering. 3. Edition. Westermann Schulbuchverlag, Braunschweig 2000, ISBN 3-14-221500-X .

- Max Bohner, Richard Fischer, Rolf Gscheidle: Expertise in automotive technology. 27th edition. Verlag Europa-Lehrmittel, Haan-Gruiten 2001, ISBN 3-8085-2067-1 .

- Peter A. Wellers, Hermann Strobel, Erich Auch-Schwelk: Vehicle technology expertise. 5th edition. Holland + Josenhans Verlag, Stuttgart 1997, ISBN 3-7782-3520-6 .

- Werner Schirmer (Ed.): Technical noise protection. Springer, Berlin / Heidelberg 2006.

- W. Fasold, W. Kraak, W. Schirmer (Hrsg.): Taschenbuch Akustik. VEB Verlag Technik, 1984.

- Reinhard Scholzen : Quieter, but not dangerous. In: Die Polizei 8, 2019, pp. 249–251.

See also

Web links

- RAL quality association for splitter silencers < https://www.guete-schall.de > /