Hydraulic cylinder

The hydraulic cylinder is a working cylinder operated with a fluid , also referred to as a hydraulic linear motor , and as a rule counts as a prime mover (drive) to the hydraulic consumers ( slave ) if it uses the energy of the hydraulic fluid that is supplied by a hydraulic pressure accumulator or a hydraulic pump , converted into a linear movement .

Designs

Hydraulic cylinders are available in various designs. In addition to DIN / EN standards, there are also company-specific standards for the piston and rod diameters . The predominantly used hydraulic cylinders are round cylinders according to ISO 6022 and DIN 24333, as well as tie rod cylinders according to ISO 6020/2 and DIN 24554.

Single acting cylinders

Single-acting cylinders only have one piston side to which hydraulic fluid is applied. Work can only be done in one direction. The return movement takes place through its own mass or an external force (e.g. a spring). Lifts often have single-acting cylinders.

Double acting cylinders

With double-acting cylinders, there are two opposing piston surfaces that are exposed to hydraulic fluid. The cylinder has two active directions of movement.

Differential cylinder

A differential cylinder has a piston rod on only one side of the piston surface. As a result, it has two effective areas of different sizes: On the one hand, the area on the piston side, which acts completely, and, on the other hand, the area on the rod side, where only the ring area acts. The ratio of piston area to ring area is denoted by. As a result, the differential cylinder normally extends and retracts at two different speeds: Retraction is faster, but it also develops less force. Operated only in a closed control loop, it follows the speed specified by the setpoint.

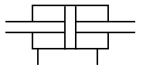

Synchronous cylinder (synchronous cylinder)

A synchronous cylinder (also called synchronous cylinder) has a piston rod on both sides of the piston surface. The volume of the hydraulic oil flowing in and out is therefore always the same and therefore it moves in and out at the same speed. Synchronous cylinders can also be implemented with just one piston rod. A special shape of the piston rod with internal bores ensures that the area ratios are the same.

Tandem cylinder

In a tandem cylinder, two cylinders are connected to one another in such a way that the piston rod of the first cylinder acts through the bottom of the second cylinder on its piston rod. In this way, despite the small size, a greater force is achieved due to the enlargement of the overall piston area.

Plunger cylinder

A plunger cylinder (or also a plunger cylinder ) does not have an actual piston, but the piston rod serves as a piston. Plunger cylinders have a more favorable mechanical efficiency, but must be guided axially.

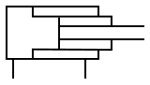

Telescopic cylinder

A telescopic cylinder consists of several cylinders built into one another. It is often built in a single-acting design, but also in a double-acting design. A combination of single-acting stages with a double-acting stage is also possible. The advantage of telescopic cylinders is that they can generate large strokes with relatively short installation lengths. As the stroke position increases, the development of force gradually decreases as the active piston area decreases. This behavior fits well for the force requirement curve when tipping a truck body.

Piston surface

The - shiny - piston should have as little roughness as possible in order to provide a good seal with respect to the mechanically pressed seal, so that only very little oil escapes when pressure is applied or when it is moved, despite high pressure. The surface is therefore smoothed by fine grinding. So that the surface is attacked as little as possible by sand or abrasive dust or chafing, pistons can be hard chrome-plated . Alternatively, a thin, hard, stainless steel layer is applied to the rotating piston by laser metal deposition .

Calculation of forces

The force F of a unilaterally acting hydraulic cylinder without loss resulting from the pressure acting in the cylinder pressure p and in the direction perpendicular standing face A :

- .

The forces of a double-acting hydraulic cylinder are to be calculated as follows:

With a diameter d K of the cylinder piston , the extending force F A results in:

- .

With a diameter d S of the piston rod , the retracting force F R results in:

- .

It should be noted that:

Example: A hydraulic cylinder loaded with 100 bar with a piston diameter of 70 mm and a rod diameter of 32 mm results in the following extending force:

The retracting force of the same cylinder is calculated as follows:

38.48 kN corresponds to an applied mass of 3.92 tons .

Alternatives

As alternative linear drives there are pneumatic cylinders , lifting bags , screw drives or rack and pinion drives as well as electric cylinders .

See also

literature

- Standard ISO 6020/2 and DIN 24554: tie rod cylinder

- Standard ISO 6022 and DIN 24333: Cylinders in round design

Web links

Individual evidence

- ↑ Environmentally friendly steel coating: Steel innovation award for the Fraunhofer ILT ilt.fraunhofer.de, June 14, 2018, accessed December 9, 2018.