Expansion tank

Expansion vessels (abbreviation ADG ), also expansion vessels or pressure expansion tanks , are components in hydraulic systems that absorb the changes in volume of the hydraulic fluid between the minimum and maximum temperature and thus keep the pressure largely constant ( pressure maintenance ).

The most common areas of application for expansion vessels are heating systems , industrial water , solar (with a water- glycol mixture) and hydraulic oil circuits.

Without an expansion vessel, water would be lost through the safety valve every time a drinking water storage tank is heated up ; Water would be lost in heating systems and air would be sucked in when the system cools down.

Expansion vessels are often designed as membrane expansion vessels ( MAG abbreviation ). Technically analogous working diaphragm accumulators , but their intended use, the storage of energy and the damping of pressure surges is. Diaphragm accumulators for hydraulic applications are also called bladder accumulators .

purpose

The volume of liquids increases with an increase in temperature and decreases with a decrease in temperature, as long as the density anomaly of water at 4 ° C is ignored. Due to the low expansion capacities of the pipe materials, this can lead to a very strong increase in pressure even with a slight increase in temperature. Without additional measures such as B. Compensating tanks , this pressure increase can lead to the destruction of pipes and pressure vessels .

The volume change of a liquid per Kelvin temperature change is described by the media- dependent cubic expansion coefficient :

Rule of thumb: one liter expansion volume per kW systems performance .

If the expansion vessel is incorrectly designed or defective, the pressure difference can significantly affect the efficiency of the heating system, even if it is still working: an efficiency loss of up to 10% is quite possible here.

Executions

Closed

Pressure maintenance via pre-tensioned gas cushion.

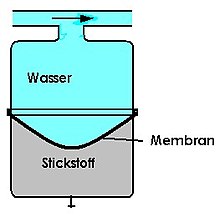

Diaphragm expansion tank

Membrane expansion vessels are equipped with a flexible rubber membrane that separates the liquid from the gas cushion, and thus largely prevents gas transfer into the liquid. There is no need for system maintenance that would otherwise be necessary , which is why only this type of construction is used in modern heating and solar collector systems.

When heated, the almost incompressible liquid expands and compresses the gas cushion on the other side of the membrane. Due to the flexible membrane, the pressure between the liquid and the gas cushion is equalized , provided that the system pressure at the lowest temperature is above the preload pressure of the membrane. The gas cushion can be viewed as an ideal gas . The relative pressure change in the system with a change in temperature is then proportional to the relative change in volume of the liquid (formula for hydraulic capacity, see above).

Nitrogen is usually used as the gas , since atmospheric oxygen would contribute to the aging / embrittlement of the rubber membrane. The water lies above the air cushion so that hot water that is pushed in does not come into contact with the membrane immediately, which also contributes to its durability.

When dimensioning a diaphragm expansion tank, the following must be taken into account:

- Liquid volume

- lowest and highest temperature of the heat transfer medium

- cubic expansion coefficient of the liquid

- the highest permissible system pressure.

The volume of the expansion vessel must be such that the pressure at the highest temperature in the system is not excessively exceeded and at the lowest temperature in the system it is not excessively undershot. When using liquids other than water (e.g. a mixture of ethylene glycol and water), make sure that the expansion coefficient is significantly higher than that of water and that the volume of the expansion vessel must be correspondingly larger.

Basically, there are four different states of diaphragm expansion vessels:

- Without pressure on the water side: The nitrogen has pressed the membrane completely against the container wall. The pressure can be controlled and adjusted according to the manufacturer's instructions and the calculation.

- Pressure loaded on the water side when the system is cold: the nitrogen and the water are "in balance", the water has detached the membrane from the tank wall.

- Pressure loaded on the water side when the system is warm: The nitrogen is compressed by the change in volume of the heating water.

- Pressure loaded on the water side without nitrogen cushions: The nitrogen has escaped and the ADG cannot do its job.

Closed without membrane

In the case of closed expansion tanks without a membrane, the hydraulic fluid in the tank is directly overlaid with pressurized nitrogen (direct contact of fluid and gas). They are usually provided with a nitrogen make-up device, which is why they are only used in special cases.

Open

Open expansion vessels are installed at the highest point in the circuit (pressure maintenance above the drop height ) and are connected to the hydraulic system via a safety line and cannot be shut off. This arrangement is used u. a. for power transformers in substations and power stations that are filled with transformer oil.

For heating systems with open pressure compensation vessel is air to oxygen in the water dissolve and corrosion cause. That is why this design can only be found in old heating systems.

Pump pressure maintenance

Pump pressure maintenance is used in systems with very large volumes of liquid : if the pressure drops, a dictation pump pumps water into the system; if the pressure increases, water is directed into an unpressurized collecting container via overflow valves or pressure-dependent solenoid valves . This usually has a rubber membrane to prevent the diffusion of atmospheric oxygen into the liquid.

Special requirements

- The ADG is part of the safety equipment of hot water heating systems and must be serviced annually in accordance with DIN EN 12828.

- Closed hydraulic circuits with expansion tanks must be equipped with a safety valve, since if the membrane is damaged and gas is lost, overpressure can occur in the system.

- The operating temperature of the membrane is limited depending on the MAG type ( drinking water & heating usually approx. 90 ° C, solar approx. 130 ° C or higher). If the operating temperature of the system is higher, an intermediate tank must be installed in front of the diaphragm expansion tank. The temperature is stratified in this and cooling takes place.

- A diaphragm expansion vessel in the drinking water network must have a once-through have to Legionella avoid education.