Industrial camera

Industrial cameras are used for simple monitoring tasks and for metrological tasks for quality control using image processing . They are characterized by their robustness and high image quality. In contrast to conventional cameras, they usually have no control elements such as buttons, switches or the like. In the early days, cameras with an analog output were used (e.g. video signal in PAL format), with the image signal being digitized by means of a frame grabber in the processing computer.

In the meantime, cameras with digital interfaces such as B. USB , FireWire and Ethernet compared to cameras with an analog interface. Standards were an important concern when introducing digital interfaces. These are intended to ensure that cameras from different manufacturers and versions are interchangeable and can continue to be used by the same PC systems for evaluation. In addition to the standards for the physical transmission of data, EMVA also used the GenICam standard, a generic software interface that separates the form of the data flow from the physical interface and is intended to ensure even more compatibility.

The latest developments are in the direction of performing image processing (or at least part of it) in the camera itself (so-called “intelligent cameras”). This significantly reduces the volume of data to be transferred on the interface, and no additional computer is required. These cameras often even have digital inputs and outputs so that they can autonomously take over simple control tasks (e.g. sorting out defective parts on an assembly line).

Physical interface standards

- Camera Link

- GigE vision

- FireWire

- USB (new USB 3)

- CoaXPress

Analog and digital output

Some advantages of cameras with a digital output compared to cameras with an analog interface ( video signal ) are:

- Higher resolution

- faster reading of the images

- lower image noise

- Progressive Scan : The image data are read out line by line.

- Greater distances between the camera and computer

- Less cabling effort

- Connection of several cameras to one FireWire / USB / Ethernet bus

- Partial readout ( ROI ) of the camera sensor allows the frame rate to be increased

- Binning (interconnecting neighboring pixels) increases the light sensitivity and frame rate

functionality

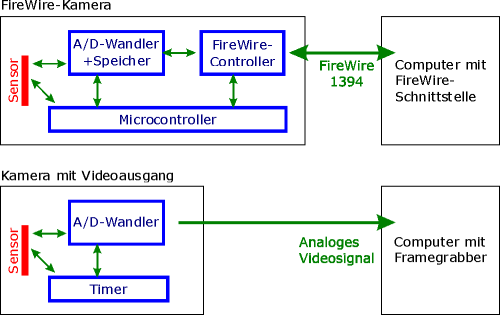

A camera with a digital output consists of at least the following components:

- Image sensor (CCD = CCD sensor or CMOS = CMOS sensor )

- Analog-to-digital converter

- microprocessor

- Bus controller

Example of a FireWire camera

In a FireWire camera , a microprocessor controls communication and data exchange between the internal components. The FireWire - Controller communicates with the connected devices, the FireWire bus means DCAM protocol. Control commands are sent from the computer to the camera, acknowledged by it and the digital image data are transferred to the computer. A camera with video output consists of an image sensor , timer and analog-to-digital converter . Some cameras with video output also have a ( serial ) interface for parameterizing the camera.

Individual evidence

- ↑ Archive link ( Memento of the original from October 11, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , GENiCAM standard, hosted by EMVA

- ↑ Post CoaXPress in English Wikipedia