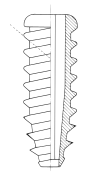

Interference screw

Interference screws are implants that are used in the surgical reconstruction of a ligament or tendon to fix the ligament or tendon. Interference screws are mainly used for the reconstruction of torn cruciate ligaments ( cruciate ligament tear ).

The name interference screw is derived from the English words interference screws . Interference fit is the English term for a interference fit (press fit). This means that the largest dimension of the hole - in the specific application the medullary canal in the bone - is smaller than the smallest dimension of the screw. From a geometrical point of view, interference screws are set screws ("grub screws").

application

Interference screws are the most commonly used implants for anatomical fixation. They are mainly used in the reconstruction of cruciate ligament ruptures. By anchoring the grafts, the cruciate ligament plasty is firm immediately after the reconstruction. The transplant is integrated into the bone at an early stage, which enables the patient to rehabilitate early.

Fixation with interference screws is a safe and proven procedure with a low rate of complications.

materials

The first interference screws were made of titanium and remained permanently in the patient's bone after implantation. In some patients this led to metal hypersensitivity and stress factors in the bones. Another problem with metal screws is that when the screw is screwed into the bone canal, the graft can be injured by the sharp-edged coils. In order to avoid possible long-term complications, which for example could result in the removal of the implants from the bone, bio-resorbable screws were developed. These screws are made of biodegradable polymers such as poly- L- lactide (PLLA), poly- D- lactide (PDLA) or poly- ( L -co- D / L- lactide) (PLDLLA). Partially crystalline PLLA degrades much more slowly than amorphous PDLA. Perforated screws (see Figure 2 (52)) accelerate the growth of the bone (osseous integration) into the screw and its dissolution. Screws made from PLDLLA are quickly broken down and completely replaced with bone. Polylactide screws with calcium phosphate or hydroxyapatite as a filler are also available on the market . These screws are also bioabsorbable. After resorption, hydroxyapatite has the same properties as a human bone.

The first bioresorbable magnesium-based interference screws were approved in 2020.

The advantages of bioresorbable interference screws are next to the small risk of damage to the graft, the simpler revision and no interference with the imaging methods of diagnosis .

Medical history

The first screws for fixation of a patellar tendon transplant were conventional AO cancellous bone screws in 1983. In 1987, grub screws, today's interference screws, were used for the first time to reconstruct a torn cruciate ligament.

Individual evidence

- ↑ F. Witte et al.: Interference screw. Patent application DE102008037202A1 dated August 11, 2008.

- ↑ a b c d A. Weiler: Anatomical "hamstring tendons" anchoring with interference screws for cruciate ligament replacement. (PDF; 793 kB) Habilitation thesis, Humboldt University Berlin, 2002

- ↑ K. Shelbourne and P. Nitz: Accelerated rehabilitation after anterior cruciate ligament reconstruction. In: Am J Sports Med 18, 1990, pp. 292-299. PMID 2372081

- ↑ B. Lembeck and N. Wülker: Severe cartilage damage by broken poly-L-lactic acid (PLLA) interference screw after ACL reconstruction. In: Knee Surgery, Sports Traumatology, Arthroscopy 13, 2005, pp. 283-286. PMID 15549256

- ↑ J. Black: Does corrosion matter? In: J Bone Joint Surg 70, 1988, pp. 517-520. PMID 3403590

- ^ W. Petersen and T. Zantop: The anterior cruciate ligament: Basics and current practice of operative therapy. Deutscher Ärzteverlag, 2009, ISBN 3-7691-0562-1 , p. 102f. limited preview in Google Book search

- ↑ BIOSURE HA. ( Page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice. Smith & Nephew GmbH brochure

- ↑ FA Barber and WD Dockery: Long-term absorption of beta-tricalcium phosphate poly-L-lactic acid interference screws. In: Arthroscopy 24, 2008, pp. 441-447. PMID 18375277

- ↑ M. Akao et al .: Mechanical Properties of Sintered Hydroxyapatite for Prosthetic Applications. In: Journal of Material Science 16, 1981, pp. 809-812. doi : 10.1007 / BF02402799

- ↑ Syntellix receives CE approval for sixth product family: new magnesium implant for cruciate ligament reconstruction. Retrieved February 4, 2020 .

- ↑ K. Lambert: Vascularized patellar tendon graft with rigid internal fixation for anterior cruciate ligament insufficiency. In: Clin Orthop 172, 1983, pp. 85-89. PMID 6822009

- ↑ M. Kurosaka et al .: A biomechanical comparison of different surgical techniques of graft fixation in anterior cruciate ligament reconstruction. In: Am J Sports Med 15, 1987, pp. 225-229. PMID 3303979

further reading

- S. Konan and FS Haddad: A clinical review of bioabsorbable interference screws and their adverse effects in anterior cruciate ligament reconstruction surgery. In: Knee 16, 2009, pp. 6-13. PMID 18639461 (Review)

- FD Bach et al: Anterior cruciate ligament reconstruction with bioabsorbable polyglycolic acid interference screws: MR imaging follow-up. In: Radiology 225, 2002, pp. 541-550. PMID 12409593

- ME Bowers, GA Tung, N. Trinh, E. Leventhal, JJ Crisco, B. Kimia, BC Fleming: Effects of ACL interference screws on articular cartilage volume and thickness measurements with 1.5 T and 3 T MRI. In: Osteoarthritis and cartilage / OARS, Osteoarthritis Research Society. Volume 16, number 5, May 2008, pp. 572-578, doi : 10.1016 / j.joca.2007.09.010 , PMID 17933559 , PMC 2424214 (free full text).

- M. Immendörfer: 5-year results after hamstring VKB plastic with titanium interference screw fixation near the joint: does the technology meet the requirements of early functional rehabilitation? Dissertation, University of Hamburg, 2008. DNB 993701175/34