Tie cables

Cable tie ( Engl. Cable lacing ) is an old method for fixing electrical lines . It is also spoken of cable tie, not to be confused with the better-known and more modern Kabelbind it . The aim is to lead a wire strand safely and efficiently to the intended connections. The technology was widespread from the beginning of electrical installation until it was almost superseded by new processes around 1960.

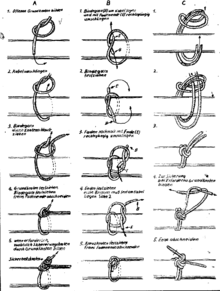

Binding is a demanding job and requires a lot of practice. The lines with a stable yarn wrapped and held in position. Waxed linen or wire was also used in the past. The cables are fixed at crucial points using a complex knot technique, comparable to a sailor's knot . While the fitter is continuously threading the tape around and through the ladder, a series of linked loops is created, similar to the double lock stitches produced on a sewing machine . In this way, stable yet filigree cable harnesses can be created without any problems . It is almost impossible for the ladder to slip in the tight corset.

Nowadays, instead of thread, flat belts made of nylon , polyester or Teflon are used. These are coated, which makes the connection even more stable. For decades, however, the binding of cables has only played a subordinate role or not at all in cost-sensitive areas. Simple assembly techniques such as ducts , installation pipes or cable ties currently determine the electrical installation. In industries with high safety standards such as avionics and space technology, however, the classic method is still used. It is even required in certain places.

Areas of application

The method is traditionally strongly represented in the aviation and seafaring industries because very durable connections are required here. In the past, tied lines were used, especially in telecommunications. Today there are only a few areas of application in which the additional effort is worthwhile. However, the process is in high demand in space travel. A clean and thorough way of working is required here. The NASA trains its astronauts so that they can apply in an emergency, the technique also.

Advantages and disadvantages

When individual cables in a bundle need to be clearly traced, e.g. For example, to rectify malfunctions in a device, the careful binding technology offers added value. The many knots and loops prevent the cables from slipping. Even sensitive sheath insulation and nearby components are not damaged as severely by the cords as cable ties. Nonetheless, binding remains a slow and complicated type of laying, the professional execution of which requires a lot of training and skill.

Examples

Linen and square knots form a Nomex weave

Marlschlag binding

NASA's Mars Exploration Rover with neatly tied harnesses

Occupational safety

Slim electric screwdrivers are ideal for binding and tightening . The yarn can cut into the hands, which is why protective gloves are recommended. A basic understanding of knots is beneficial when tying cables.

Individual evidence

- ↑ mercateo Germany: Tie thread for cable ties . Retrieved November 5, 2011.

- ↑ a b c Tec-Alert Newsletter: Basics of Cable Lacing . July 12, 2011. Retrieved November 7, 2011.

- ↑ FAA Advisory Circular 43.13B paragraph 11-158: INSPECTION AND CARE OF ELECTRICAL SYSTEMS (PDF; 2.0 MB) August 9, 1998. Accessed November 7, 2011.

- ↑ NASA-STD-8739.4; Change 6; P. 40–43: FORMING WIRES INTO CABLES AND HARNESSES . March 29, 2011. Retrieved September 2, 2015.