Crown glass

In the manufacture of color-corrected lenses, crown glass is all optical glasses with an Abbe number greater than 50.

composition

- Quartz (SiO 2 ): about 73%

- Sodium Oxide (Na 2 O): about 5%

- Potassium oxide (K 2 O): about 17%

- Calcium oxide (CaO): about 3%

- Aluminum oxide (Al 2 O 3 ): about 2%

properties

Due to the high proportion of quartz, crown glass is difficult to melt. With a value between 1.5 and 1.6, it has a refractive index that is significantly lower than that of flint glass . With an Abbe number of typically around 60, its dispersion is comparatively small.

use

Crown glass is used for the production of high-quality glassware and as mirror glass.

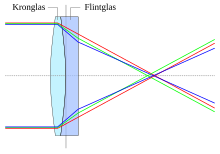

Ophthalmic glasses and lenses for light microscopes , telescopes , objectives and other optical instruments are made from optical crown glass . In the achromat , the low dispersion of crown glass in connection with flint glass, which shows high dispersion, is used for color correction.

history

Crown glass has been known for centuries. It got its name from the oldest method of window glass production in England. The required glass mass was removed from the melt flow with the glassmaker's pipe and a hollow ball was first blown from it. The glassmaker's pipe was then held up and turned quickly, the ball flattening out. Then a staple iron was placed opposite the glassmaker's pipe and the pipe was blasted off, so that a circular hole was created. After renewed heating, the pre-blown ball was turned with the tacking iron.

Here the opening widened; its edge bent outward due to centrifugal force and assumed the shape of a crown. Further turning resulted in a circular pane of glass, which was used as a window pane after being separated from the stapling iron. In some old churches and houses, such round panes set in lead can still be found. They are also called Butzenglas or Butzen disk .