macadam

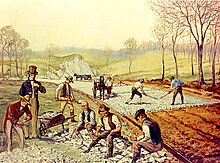

The term macadam describes a special construction method of roads in which three layers, each with broken and well-compacted aggregates of different sizes, form the road surface . This type of construction was developed by the Scottish inventor John Loudon McAdam at the beginning of the 19th century to improve the durability and resilience of the existing roads (often packaged layers ). Roads paved in this way were described as macadamized .

With the increasing motorization, this original design proved to be inadequate, especially due to the development of dust. For this reason, people later switched to binding the aggregates with tar or (less often) with bitumen ( tar-bound macadam ). Ultimately, this further development could not prevent the macadam construction from being replaced by other construction methods. The reasons for this were, in particular, the high level of mechanization in road construction (macadam roads can only be built with a large proportion of manual paving) and the poor stability or evenness when there is heavy traffic.

In modern parlance, the meaning of the term “macadam” has changed somewhat. In most cases it is commonly used to describe a surface that is only bituminous on the surface (in contrast to asphalt ). In addition to water-bound surfaces , as for example in the construction of rural roads are used, the macadam construction attributed.

Construction

The structure originally developed by McAdam in the early years of the 19th century consisted of three layers of gravel of different grains, which were applied to a vaulted base, with lateral ditches for drainage . The lower two layers consisted of crushed stone (hand-broken, grain size up to 8 cm) in a total thickness of 20 cm, on top of which a layer of chippings (grain size up to 2.5 cm) was applied in a thickness of 5 cm. The layers were compacted individually with a heavy roller and with the addition of water. This ensured that the angular granules wedged into one another. This basic construction is sometimes called a water-bound macadam . Although this method was very labor-intensive, it produced a firm and self-draining road surface.

Further development to the tar-bound macadam

With the advent of motor vehicles, macadam roads became a serious problem. The negative pressure under fast-moving vehicles sucked the dust and fine sand particles out of the surface, which meant that the coarser particles also lost their connection. There were also unpleasant clouds of dust. In 1902, Ernest Guglielminetti solved the task of dust-freeing initially by adding tar (binding agent obtained e.g. from lignite or other organic compounds), which resulted in what is known as tar - bound macadam ( tarmac ). In the course of time, other bound macadam structures were developed. With the ban on using tar in road construction (for example since 1984 in West Germany), the use of bitumen as a binding agent was adopted.

species

There are three types of bound macadam construction methods:

- First of all, before paving, the fine rock grains are mixed with the binding agent and then scattered on the lower unbound layers. This construction method has the designation Streumakadam or Asphaltstreumakadam .

- If the coarser aggregates underneath are also mixed with the binding agent before paving , one speaks of mixed macadam or asphalt mixed macadam .

- Impregnation macadam or asphalt impregnation macadam is created by filling a gravel base layer with raw chippings and then impregnating it with a bituminous binder. Finally, grit is applied and rolled in. The result is also known as a drinking blanket .

literature

- Siegfried Velske, Horst Mentlein, Peter Eymann: Road construction technology . Werner Verlag, Düsseldorf 2002, ISBN 3-8041-3875-6 , p. 167 f .

- Dietmar Grütze: Building Lexicon . Carl Hanser Verlag, Munich 2007, ISBN 978-3-446-40472-4 , p. 173 .