Packaging technologist

The packaging technologist has been the successor to the state-recognized apprenticeship as a packaging mechanic in Germany since August 1, 2011 .

Duration of training and structure

The training period to become a packaging technologist is three years. The training takes place at the training company and vocational school .

The new training regulations provide for two elective qualifications each lasting eight weeks:

- Metalworking

- Control technology

- Special manufacturing processes

- Computer-aided sample creation

In addition, the company can choose two further elective qualifications, each lasting ten weeks. You can choose from:

- Die making

- Finishing technology

- Control room technology and inline production

- laboratory

- Mechanics and control technology

- Computer-aided packaging development and design

Aim of the reorganization

The current training regulations from 2001 are not flexible enough. It is therefore planned to introduce elective qualification units into the training regulations. This means that common content is included in the training regulations that all trainees should learn. In addition, however, there is modular content that the company can select according to the trainees' inclinations and their operational needs.

The new job title is intended to reflect technical progress in the manufacture of packaging materials and to make it more attractive for young people.

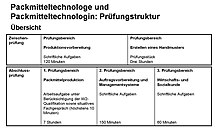

Intermediate and final exams

In this profession, there is a conventional intermediate and final examination (i.e. no extended final examination ). The intermediate examination serves to determine the level of training of the trainee. It should give him information about where possible deficits lie that have to be compensated for by the final examination. The final examination is intended to determine whether the trainee has acquired the professional ability to act . He is supposed to prove “that he has mastered the necessary professional skills, has the necessary professional knowledge and skills and is familiar with the teaching material to be taught in vocational school, which is essential for vocational training. The training regulations are to be applied. ". The examination tasks are provided by the ZFA Druck-Medien . The exam takes place in front of an IHK .

midterm exam

The intermediate examination covers the contents of the first three semesters of training and should take place before the end of the second year of training. The two test areas production preparation and creating a manual sample are provided.

In the production preparation examination area, the trainee should plan work steps to implement customer requirements, specify work equipment, select materials, take into account the requirements of occupational health and safety and environmental protection as well as economic efficiency, implement order data for setting up and controlling the packaging machine, the selection of materials and tools and production - and show storage options and indicate quality assurance measures. This evidence is provided through the processing of written tasks in a scope of 120 minutes.

In the test area creating a hand sample, he produces an examination piece in three hours. It should show how to design packaging materials while observing technical and organizational requirements, how to make technical drawings by hand and how to produce samples manually.

final exam

The final examination consists of three examination areas:

- Packaging production,

- Order preparation and management systems as well

- Economics and Social Studies.

Testing area packaging production

The test participant sets up a machine or a system for two production processes in seven hours and drives it. The optional qualification unit specified in the training contract is taken into account. In addition, a situational technical discussion is held, which lasts a maximum of 10 minutes.

He shows that he procures the documents and materials required for the work order to set up packaging machines, carries out and documents work processes in accordance with economic, ecological, technical and organizational requirements in a customer-oriented manner, equips machines and systems as well as starting and controlling production, checking the production result , assess and optimize. Furthermore, it is proven that packaging materials can be produced economically and in due time in the specified quality and that measures to remedy faults can be initiated, maintenance and servicing work can be carried out and safety devices can be checked for their effectiveness. He should also prove that he is able to communicate and document process data and production conditions.

Examination area order preparation and management systems

In 150 minutes, the exam participant completes written tasks on the following topics:

- Customer-oriented planning of work processes taking into account economic, ecological, technical and organizational requirements,

- Consideration of upstream and downstream production areas,

- Structuring and evaluation of machine data as well as subsequent compilation and backup of the data for the order documentation,

- Use of information on machines and systems, the production process, materials and tools and the development of problem solutions,

- Explanation of the instruments and regulations of quality and hygiene management ,

- Execution of process-related calculations.

Examination area economics and social studies

The exam participant completes written tasks in 60 minutes. He proves that he can present and assess general economic and social relationships in the professional and working world.

Weighting of the examination areas

The examination areas are weighted as follows:

| Exam area | weighting |

|---|---|

| Packaging production | 60 percent |

| Order preparation and management systems | 30 percent |

| Economics and Social Studies | 10 percent |

Passage regulation

The examination has been passed if the overall result is at least "sufficient", in the examination area "packaging production" with at least "sufficient", in at least one of the other examination areas with at least "sufficient" and in none of the examination areas with "unsatisfactory".

Oral supplementary examination

An oral supplementary examination of around 15 minutes is possible in the examination areas “Order preparation and management systems” or “Economics and social studies” if the final examination can be passed. The prerequisite is that these examination areas were rated worse than "sufficient". A supplementary oral examination to improve the grade is not possible.

Credit options

A trainee who has successfully completed his / her professional training as a machine and system operator with a focus on print finishing and paper processing can shorten the duration of training as a packaging technologist by two years.

Individual evidence

- ↑ New professions for a new world of work. In: ausbildungplus.de. Federal Institute for Vocational Education and Training (BIBB), June 2, 2011, accessed on June 17, 2016 .

- ↑ Packaging technologist - packaging technologist. (PDF; 992.1 kB) In: bvdm-online.de. Central Technical Committee for Vocational Training in Printing and Media (ZFA), June 2011, accessed on June 17, 2016 .

- ↑ Project description for the packaging technologist at BiBB ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice. . Retrieved November 12, 2010.

- ↑ § 38 BBiG

Web links

- Ordinance on vocational training for packaging technologists (PackmAusbV)

- Presentation of the profession on the career page of the Main Association of Paper and Plastic Processing eV (HPV) . Retrieved January 2, 2014.

- "Well packaged is half sold. Profession of the week: packaging technologist" . Zeit Online, April 13, 2014. Accessed August 1, 2016.

- Article by the bvdm on the packaging technologist . Retrieved June 17, 2016

- Brochure from ZFA Druck-Medien on packaging technologists , accessed on July 14, 2011, PDF, 1047 kB.