Graft copolymerization

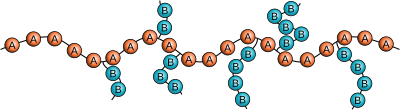

In the graft copolymerization is a technique for the preparation of polymers whose main chain is formed starting point for further chains of another type of monomer. The result is a copolymer whose main chain is followed by chains of another monomer type in a comb-like manner. This offers a further possibility of developing plastics with newly defined properties.

synthesis

There are essentially three methods used:

- 1. "grafting to": A chain that is already growing is added to the backbone of an existing one

- 2. "Grafting from": Starting from an already existing polymer, the growth of a further chain begins

- 3. via macromonomers, i.e. by bringing together existing polymer chains

Grafting To

In the most commonly used method, an existing polymer is exposed to gamma radiation, which creates free radical sites along the backbone, which can then form the starting point for further radical polymerization .

In this way, for example, the very impact-resistant rubber HIPS ("high-impact" polystyrene) is produced by polymerizing styrene onto a polybutadiene chain.

In a further process, an already existing polymer and the monomer to be added are dissolved in a non-polar solvent (e.g. dichloromethane ) and a Lewis acid (coinitiator) is added. The Lewis acid now withdraws electrons from the polymer in several places. The positively charged points that arise in the process then represent the starting point for the cationic polymerization with the monomer.

Grafting From

This technology attaches already existing points in the main chain, which can be attacked by a growing chain. In the case of an anionic polymerization, these can be, for example, electrophilic groups, such as carbonyl or nitrile groups introduced by phosgene .

Via macromonomers

In this process, an existing polymer is subsequently functionalized along the side chain. One example is the conversion of a polymer with OH groups along the backbone, which can be converted to the respective esters with polymers with terminal carboxylic acid chloride groups . One advantage is that, in contrast to the two aforementioned methods, both the points of attack for the newly growing chains and the length of the side chains can be better defined in advance. The distance between two side chains is also referred to as a “spacer”. The disadvantage is the higher technical and financial effort. In this way, for example, comb polymers can also be produced.

The graft polymerization is subject to the same principles as the copolymerization .

literature

- JMG Cowie: Chemistry and Physics of Synthetic Polymers . London, 1997, ISBN 3-540-67052-1