Pump turbine

A pump turbine , also known as a pump turbine , is a type of machine set in pumped storage power plants . It consists of an electrical machine that can work as a motor or generator and a flow machine that can work both as a turbine and as a pump . The term is sometimes only used for the flow machine alone, which is designed as a Francis turbine .

Working method

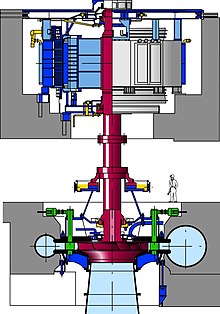

The pump turbine is usually designed as a machine with a vertical axis. The motor generator is arranged above the turbo machine. In pump operation, it drives the flow machine and thus conveys the medium; in turbine operation, it takes the torque from the flow machine through which the medium flows and generates electricity.

To switch between the two operating modes, the direction of rotation of the machine set and the direction of flow of the medium in the turbo machine must be changed. This means that the machine block must be stopped to change the operating mode.

To start up in turbine operation, water is applied to the turbine until it reaches the synchronous speed of the motor generator so that it can be synchronized with the network . Operation as a pump requires starting up the motor generator in the opposite direction of rotation, which is achieved with special equipment.

application

Voith first supplied pump turbines for the Pedreira power plant near São Paulo in Brazil in 1937 . They had an output of 5.3 MW and use a drop height of 30 m. In Switzerland, the first pump turbines were installed in 1968 in the Robiei headquarters of Maggia power plants .

From the middle of the 20th century, the pump turbine became the common solution for pumped storage power plants because, in contrast to ternary machine sets, it only requires two instead of three machines on the shaft train, which reduces the overall height and the dimensions of the power plant construction. The disadvantage is the complicated switchover between turbines and pumps, which can only take place when the system is shut down. Furthermore, the efficiency of the turbomachine is not optimal, since it cannot be optimized for the pump and turbine operation at the same time. Large heads can be controlled more easily with ternary machine sets.

A special design of the pump turbine is the design of the Isogyre pump turbine developed by Ateliers des Charmilles in Geneva , in which the direction of rotation is not reversed. It uses an impeller that is placed back to back with a turbine in the same volute. The function is only switched over by the control unit.

Variable speed version

The pump turbine can also be designed with variable speed. The main advantage of this design is that the power consumption from the network can be regulated by changing the pump speed. Furthermore, the selectable speed of the turbine can improve the partial load efficiency. The pumped storage power plant in Europe, which was equipped with variable-speed pump turbines, what the Goldisthal power plant . The motor generator can be designed both as a double-fed asynchronous machine and as a converter-fed synchronous machine .

Double fed asynchronous machine (DASM)

In this case, the motor generator is designed as an asynchronous machine with a wound rotor, which is supplied with power by a direct converter . The speed can be regulated in a range from 90 to 104% of the nominal speed of the machine. This solution was used in Goldisthal.

Converter-fed synchronous machine

In this solution, the stator of the synchronous machine is supplied with energy via a frequency converter with a load-commutated inverter. In contrast to the solution with DASM, the converter has to be designed for the full power of the motor generator, for which the pump turbine can be controlled in the entire frequency range.

Web links

Individual evidence

- ^ Jean-Emile Graeser: The electromechanical equipment of the Robiei cavern center . 1970, p. 219 , doi : 10.5169 / SEALS-84449 .

- ↑ Oliver Jansen, Tobias Schöner: Pumped storage power plants - comparison of different concepts to secure the standard needs of the future . In: Dresdner Wasserbauliche Mitteilungen . S. 46-48 ( baw.de [PDF]).

- ^ Daniel Schäfer, Jean-Jacques Simond: Adjustable speed Asynchronous Machine in Hydro Power Plants and its Advantages for the Electric Grid Stability . 1998, p. 1 .

- ^ Goldisthal Pumped Storage Plant: More than Power Production. March 1, 2007, Retrieved June 8, 2020 (American English).

- ↑ Christoph Nicolet, Oliver Braun, Nicolas Ruchonnet, Antoine Beguin, Johann Hell, Francois Avellan: Full Size Frequency Converter for Fast Francis Pump-Turbine Operating Mode Transition . S. 2–3 (English, powervision-eng.ch [PDF]).