Grinding root

The Schleifkothengrund is an approximately three kilometer long valley section on the upper reaches of the Steinbach, it belongs to the Steinbach district in the Wartburgkreis in the Thuringian Forest .

description

The Schleifkothengrund is considered to be a narrow, steep-walled Kerbtal valley that cut up to 200 meters deep into the mountain range. The rocks here are called Ruhla granite, Liebenstein gneiss and Steinbach eye gneiss. The vegetation on the hillside is determined by the beech forest, the stream is lined with an ash and alder wood strip. The humid environment caused by the brook favored the spread of ferns and herbs in the soil flora. The valley is also the habitat of rare amphibians and insects.

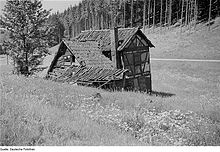

The now wooded valley has been a center of the division of labor since the Middle Ages and got its name from a collection of 7 grinding mills (grinding knots) in which the blanks of the knife blades were processed for centuries with the power of the mountain stream.

Of the mills and workshops of the blade grinder, which in the 17th century with the neighboring Ruhlaer and Brotteroder had allied labor blade forging, little evidence remained, numerous grinding stones are found in the memory of the set before the Second World War craft.

The structure of a grinding feces can be studied on models (for example also in the city information center of Ruhla). The impact water (upper water) was fed to the mill through a weir from the mountain stream. The mill water (around 100 liters per second) flowed through a wooden channel into the water wheel, the typical diameter of which was designed at 4 to 4.5 m for small wheels, the largest Steinbach mill wheel was even 8.4 m in diameter. With the resulting rotary movement, under optimal conditions, a drive force of 6 to 11 hp was generated, which was distributed to the existing grindstones of the mill via the drive shaft and a wooden gear drive. The sandstone grindstones, which weigh up to a ton, were mostly obtained from quarries in the Gotha Seeberg. To replace used grindstones or in the event of technical defects, usually when a wooden part of the gearbox broke, the mill work had to be interrupted, which reduced earnings and profits. From 1875 onwards, as a result of the industrialization of iron foundries, robust gearwheels in standardized sizes and in large numbers were offered inexpensively. The use of leather or cotton drive belts also improved the efficiency of the mill. Despite the high costs, the grinding mills switched to the robust technology. But this, too, had its pitfalls: the heavy technology began to vibrate when a part (mostly the grinding wheel) was unbalanced, the mills, which were still made of wood, were no longer able to withstand the loads and began to warn of an imminent collapse by loud groans and creaking in the framework . After the First World War, the number of mills fell rapidly, and in Steinbach from 1915 the electric motor replaced the water drive as an energy source. Semi-automatic grinding machines bought from the Solingen knife factory replaced traditional technology by 1930. The grinding knots, which were optimized for knife sharpening, could not be used for other applications and were abandoned by their owners. The last grinder was torn down in Steinbach after 1980.

Up to 8 sanders and polishers worked in each sanding feces, the working conditions were harmful to health due to the sanding dust and the high humidity, but the earnings were relatively high with the corresponding quality. Many Steinbacher knife sharpeners died at the age of 40 from "Steinbacher's disease", as the dust lung was called in the village.

Thematic hiking trail

In cooperation with the Ruhla tobacco pipe and local history museum , the Steinacher Heimat- und Trachtenverein and the nature park administration, branch office Alte Warth, the idea of a thematic hiking trail was implemented:

- The knife trail begins in Ruhla at the tourist information office. In the tobacco pipe museum a reconstructed Ruhla blade forge can be viewed. The path leads via Dornsengasse and Mühlrain into the former mining area on the Alten Ruhl and follows the paths of the knife carriers to the top of the pass at the Schillerbuche on the Rennsteig. The path now leads downwards via Mühlbergskopf into the Schleifkotengrund, where the processing took place, and finally to Steinbach, where the knives were provided with handles. The path ends at the Steinbach local history museum.

In the eastern part of the Schleifkothengrund, the first ski jumping hill was built in the 1930s and inaugurated in 1934. A wooden memorial plaque was set up at the ski jumping facility, which informs about the first hill records and competitions.

Notes and sources

- ↑ a b c Gernot Malsch: The Steinbacher Schleifkotten . In: Altensteiner Blätter . Yearbook 1994. Schweina 1994, p. 56-65 .

- ↑ grinding root. In: Between Ruhla, Bad Liebenstein and Schmalkalden (= values of our homeland . Volume 48). 1st edition. Akademie Verlag, Berlin 1989, pp. 70–71.

- ↑ Leaflet on the knife path

Coordinates: 50 ° 50 ′ 16 ″ N , 10 ° 22 ′ 29 ″ E