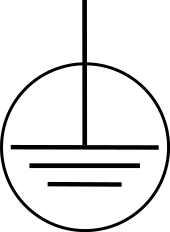

Protective earthing

According to DIN VDE and NIN , protective earthing is defined as: " Earthing of a point or several points of a network, a system or equipment for the purpose of electrical safety" and in the ÖVE as a "measure of fault protection in which the conductive system parts to be protected are over the PE conductor is connected to a suitable earth electrode and the system parts with a fault are switched off by overcurrent protective devices ”.

In the past, the measures "protective earthing" and " protective equipotential bonding " were collectively referred to as zeroing (this is still the case in ÖVE / ÖNORM E 8001-1: 2010 and Austrian ETG 1992).

In general, it is understood to mean the continuous electrical conductive connection of all easily touchable and electrically conductive device parts (e.g. metal housing) that are not part of the operating circuit with the potential of the ground to avoid high contact voltages in the event of functional errors.

Protective earthing in the low-voltage network

There are 3 types of protective earthing in the low-voltage network:

- combined protective earthing and operational earthing

- separate protective earthing and low-resistance operational earthing

- separate protective earthing and high-resistance operational earthing

With combined earthing, one conductor of the operating circuit, usually the neutral conductor, is earthed in the vicinity of the transformer station via an operating earth. At the end user (household, trade, industry) a separate protective earth is installed in the ground. Protective grounding and operational grounding are brought together on the equipotential bonding rail. This means that there is a galvanic connection between the operating earth and protective earth.

In the separate system (separate protective earthing and low-resistance operational earthing), a conductor of the operating circuit is also earthed in the vicinity of the transformer station via the operational earth. At the end user, the bodies to be earthed are directly earthed without the operational earth and protective earth being connected to one another. There is therefore only an undefined galvanic connection between the operational earth and protective earth via the earth.

With the third earthing variant, all active parts are isolated from earth or connected to the operational earth via a high-resistance impedance. At the end user, the bodies to be earthed are earthed directly. This happens independently of the grounding of the power supply. There is therefore no galvanic connection between the operational earth and protective earth.

Protective earthing in high and medium voltage networks

In high and medium voltage networks, i.e. networks with nominal voltages greater than 1 kV , all metal construction parts in switchgear and power plants are connected to the earthing system and thus to the earth electrode via low-resistance earthing lines. In addition, all feet of the masts are earthed. Potential control is also effected by means of a control earth. In power plants and switchgear there are usually common earthing systems for the high-voltage and low-voltage networks. The earthing connections are detachably connected to the earthing busbar and are precisely labeled for better visibility.

Protective earthing for electrical railways

When it comes to protective earthing of electrical railways, a distinction is made between:

- AC and DC railways

- The level of the contact line voltage in the low-voltage or high-voltage range

Protective earthing for AC railways

In the case of alternating current railways, all conductive components that are located in the overhead contact line area are connected directly to the running rails in an electrically conductive manner. These measures serve to protect against potential differences in the track area, because due to the earthing effect of the connected components, structures and systems, an increased rail potential is avoided. In addition, this measure also protects against indirect contact such. B. Catenary disconnection. This earthing measure, in which all running rails are specifically connected to earth and the rails are used as a return line, is also known as rail earthing . Due to the rail grounding, return currents can be carried into the public network, which, due to the different frequencies of the two systems, can affect the systems in the utility network. In addition, reverse current transfer can overload the neutral conductor , protective conductor or PEN conductor. This causes these conductors to heat up impermissibly, and these loads can even lead to a conductor breakage. For this reason, the railway grounding is brought together to a separate grounding system and galvanically separated from the grounding of the utility network.

Protective earthing for direct current railways

With DC railways stray currents occur, which is associated with corrosion of components and earth electrodes. For this reason, the running rails of DC railways must not be connected to the grounded components in an electrically conductive manner, but must even be electrically isolated from ground. For components that are electrically isolated from earth, a direct connection to the running rails is permitted. The steel reinforcement of tunnels or bridges and the steel structures in the area of bus stops are brought together and earthed separately as so-called building earth electrodes. In special cases such as B. poor soil conductivity additional measures such. B. Earthing ropes applied.

Protective measure protective earthing

The classic version of the protective measure protective earthing (today protective measure “automatic switch-off of the power supply” in TN and TT systems) was first mentioned in 1924 as a loose form of a list of measures and was incorporated into VDE 0140 in 1932. This protective measure, however, has lost its importance today and is only sporadically in the networks of utilities used.

Layout and function

The bodies to be earthed are connected to the protective earthing conductor, the mains transformer is earthed via the operational earth. With protective earthing, a short-circuit to frame becomes an earth fault. The fault current flowing via the grounding line, bringing the next upstream fuse element ( fuse , MCB ) for switching off.

Certain conditions are linked to the protective earth resistance so that the safety device can also switch off within the required short times. In the old standard, these conditions were specifically regulated for the 3 × 220 V network, in which the neutral conductor was only distributed via the earthing system, so that protective earthing could only be used for overcurrent protective devices up to 10 A. This limitation was due to the fact that in practice it is hardly possible to achieve grounding resistances lower than 2 ohms .

With the reorganization of the standard, the conditions for protective earthing as a protective measure have been tightened. So instead of the condition of the protective earth resistance R A, the loop impedance condition was introduced.

The loop impedance Z S must at least meet the condition:

Here, U N is the maximum voltage to ground 50 V (65 V earlier). The breaking current I A of the respective upstream overcurrent protective device is calculated according to the formula

determined.

I N is the rated current of the overcurrent protective device. The switch-off factor m is determined from the standardized fuse table 10-1.

The impedance Z S of the fault loop is determined either by measurement or by calculation. Due to these stricter conditions, the protective measure can no longer be used and, in the event of significant changes, must be implemented by other protective measures, e.g. B. be replaced by FI circuit breakers as a supplementary measure.

See also

Standards and other regulations

- DIN EN 50522; VDE 0101-2: 2011-11 Earthing of power systems with nominal alternating voltages above 1 kV.

- DIN EN 50122-1; VDE 0115-3: 2011-09 Railway applications - Fixed systems - Electrical safety, earthing and return line - Part 1: Protective measures against electric shock.

- DIN VDE 0100-410: 2007-06 Construction of low-voltage systems, Part 4-41: Protective measures - Protection against electric shock, Section 411.3.

- DIN VDE 0100-540: 2012-06 Erection of low-voltage systems Part 5-54: Selection and erection of electrical equipment - Earthing systems and protective conductors, Section 543.

- Technical connection conditions for connection to the medium-voltage network

literature

- Gerhard Kiefer, Herbert Schmolke: VDE 0100 and practice, guide for beginners and professionals . 14th edition. VDE Verlag GmbH, Berlin and Offenbach 2011, ISBN 978-3-8007-3190-9 .

- Klaus Heuck, Klaus-Dieter Dettmann, Detlef Schulz: Electrical energy supply. 7th edition, Friedrich Vieweg & Sohn Verlag, Wiesbaden, 2007, ISBN 978-3-8348-0217-0

Individual evidence

- ↑ DIN VDE 0100-200: 2006-06 section 826-13-09; NIN 2010, CD version 2.1.13.09.

- ↑ ÖVE / ÖNORM E 8001-1: 2010 section 3.8.12.

- ^ Friedhelm Noack: Introduction to electrical energy technology . Carl Hanser Verlag, Munich As 2003, ISBN 3-446-21527-1 .

- ↑ a b c Swiss Association of Road and Transport Experts : Earthing Manual. Railway technology regulations, Bern 2008

- ^ Christoph Rützel: Railway earthing and return current conduction. In Eisenbahn-Unfallkasse (EUK) (ed.): Bahn Praxis Spezial, 11th 2007, Bahn Fachverlag GmbH, 55013 Mainz, Printing and Design Master Printing, pp. 125–128.

- ↑ Wv Baeckmann, W. Schwenk: Handbook of cathodic corrosion protection. 4th completely revised edition, WILEY-VCH GmbH, Weinheim 1999, ISBN 3-527-29586-0 .

- ^ Wilhelm Rudolph: VDE series 39; "Introduction to DIN VDE 0100", electrical systems in buildings . 2nd Edition. VDE Verlag GmbH, Berlin and Offenbach 1999, ISBN 3-8007-1928-2 , p. 262, 263, 789 .

- ^ A. Senner: Electrical engineering. 4th edition. Verlag Europa-Lehrmittel, 1965.

- ↑ Österreichischer Verband für Elektrotechnik, Österreichisches Normungsinstitut (Ed.): Construction of electrical systems with nominal voltages of up to 1000 V ~ and 1500 V -. Part 1: Terms and protection against electric shock (protective measures). (ÖVE / ÖNORM E 8001-1).

Web links

- Medium voltage tab (last accessed March 7, 2013) (PDF; 850 kB)