Steinmetz process

The Steinmetz process was invented in 1890 by mill engineer Stefan Steinmetz and patented in 1892. It is a washing and husking process for grain that precedes the actual milling process. This removes most of the outer skin of the cereal grain. The seed coat, including vitamins and minerals, is retained.

The bitter substances in the outer shell , air pollutants such as lead , cadmium or benzopyrene as well as microorganisms and their mycotoxins are removed particularly thoroughly.

In practice, the Steinmetz process is mainly used for cereals such as rye , wheat and spelled . The resulting flour products are called stonemason flours . The bread made from it is called "stonemason bread".

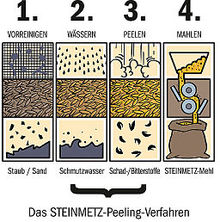

The mechanical steps of the Steinmetz process

- Dry cleaning: dust particles and foreign deposits are removed by sieving. This step is carried out on every grain.

- Washing: The grain is washed, whereby the woody fruit skin swells and begins to separate from the grain.

- Shell removal: The so-called Steinmetz shell removal (decortization) - by rubbing the grains against each other, the outer fruit peel is gently removed and sucked off with an aspiration suction.

- Milling: The grain now goes into the milling process of the mill.

Individual evidence

- ↑ Waldemar Ternes , Alfred Täufel, Lieselotte Tunger, Martin Zobel (eds.): Food Lexicon . 4th, comprehensively revised edition. Behr, Hamburg 2005, ISBN 3-89947-165-2 . , 1786.

literature

- Marlis Bach / Kurt Bach: Building blocks for health and vitality , self-published, Vienna, 2001: 168-170

- Franz Josef Steffen: Brotland Germany , Volume 2, Deutscher Bäckerverlag-Verlag, Bochum, 2000: 124-125