Troop parachute T-11

Under the program name Advanced Troop Parachute System (ATPS), the American armed forces are currently purchasing the T-11 automatic troop parachute with a new main and reserve parachute and harness as a successor to the outdated T-10 troop parachute . The main parachute with its rectangular base and low sides will replace all 52,000 T-10s used by the US Army and other states. Furthermore, the new T-11R reserve parachute replaces the old T-10R and MIRPS reserve parachutes and is now used throughout the armed forces for the MC-6 and MC-7 parachutes .

conditions

The paratroopers of the United States took almost 60 years nearly unchanged troops parachute series - the T-10th As the direct successor to the parachutes of the Second World War , it was continuously improved with a view to its functional reliability on the main canopy, the harness and the reserve parachute up to the T-10D version, without being able to adapt the sinking properties and load limits to the new requirements. Because while the parachute equipment hardly changed, the paratroopers and especially the equipment they had to carry with them became heavier and heavier.

During the invasions in Grenada (Operation "Urgent Fury") and Panama (Operation "Just Cause") , American paratroopers and rangers with an average total weight of well over 136 kg and sometimes even over 180 kg jumped off with the T-10 parachute, which has been developed for a maximum take-off weight of only 136 kg. This overloading of the T-10 not only led to a sharp increase in jump accidents (up to 10 per 1000 jumps) during these combat jumps, but also during practice jumps due to the excessive rate of descent.

The US Army was already aware of the increasing disadvantages of its jump parachute in the 80s and was looking for a successor model. With the participation of the Bundeswehr , the 3-canopy parachute T-3F was developed and tested intensively , the introduction of which was canceled at a very late stage of procurement due to fatal accidents. It was not until the late 90s that the US military resumed the search for a replacement for the T-10 and the reserve parachute T-10R or MIRPS (Modified Improved Reserve Parachute System, German: modified, improved reserve parachute system).

Under the program name Advanced Troop Parachute System (ATPS), a search was made from 1997 for a new main parachute, reserve parachute and harness with the following main features:

- Maximum jumping weight of 151 kg without harness and parachute

- Sink speed between 4.8 and 5.4 m / s with maximum jump weight

- Minimum jump height in battle of 152 m

- Maximum dropping speed of 278 km / h

- Can be used up to 2290 m above sea level and at a maximum wind speed of 24 km / h

- Opening load of max. 10 g and 15 g for the main parachute or reserve parachute on the jumper

- Reserve parachute with a maximum descent speed of 8.2 m / s

- with a system reliability of 99.93%

The target rate of descent of a maximum of 5.4 m / s was significantly below that of the T-10D, which would reduce the jumper's landing load by 40%. At the same time, the soldier should still reach the ground quickly in order to be only briefly exposed to enemy weapons and, above all, the wind. A turnability or controllability of the screen was not required, because the ATPS was intended for mass jumping from low heights.

Development and testing

As part of a market study, all available domestic and foreign troop parachutes were checked to determine whether they were eligible for the ATPS and whether they met the technical requirements. This should prevent costly new developments and accelerate the introduction to the troops. In the study, five promising applicants were identified, commissioned with the further development and tested in a first test phase on the Yuma Proving Ground 2004 with the dropping of sensor-equipped dolls. After evaluating the data obtained and the packing and repair processes, two parachute models were selected for further testing and designated as XT-11 and XT-12. The Airborne Systems consortium's XT-11 consisted of a main square canopy developed by Para-Flite, an Irvin-GQ reserve parachute based on the current British Forces reserve parachute, and a harness made by Aircraft Materials Limited, and was named MTR-1 in-house designated. The competitor model, known as the XT-12, had been developed by Irving Aerospace as the 8mLLP (8 meter Low Level Parachute) since 1993 and introduced into the British armed forces.

The soldiers' test jumps in Fort Bragg, NC, planned for the end of 2004, were canceled because the significantly larger main canopy saw the risk of collisions in the air if the aircraft dropped out of both doors at the same time. After this assumption could be refuted by further dolls dropped, the first soldiers jumped with the umbrellas. As a result, the Airborne Systems XT-11 was selected as the winner in the ATPS program and further tested for operational capability. During this test, which comprised thousands of jumps, a fatal accident occurred, as a result of which jumping operations were suspended for the time of the investigation. The newly introduced troop parachutes MC-7 and MC-6, which both use the identical reserve parachute or reserve parachute and harness, were also affected by the restriction on jumping operations. The investigation uncovered problems with packing the main canopy without questioning the general safety of the parachute system.

Due to the investigations, the serial production and introduction of the new troop parachute, now known as the T-11, was delayed. Originally, the first units were to be converted to the T-11 in 2005, but the conversion was not completed until 2008 for the first user, the 75th Ranger Regiment. In the following years, other associations followed and by 2016 all around 52,000 T-10 parachutes are to be replaced by the T-11. In addition to Airborne Systems, the United States commissioned BAE Systems and Aerostar International Inc. to produce the parachutes for a total of $ 220 million. The program suffered another setback with a new fatal accident in 2011. The investigation again revealed systematic inadequacies in the packing process, quality control and inspection. At the beginning of 2012, jumping and training operations were resumed with the T-11. In 2011, major safety restrictions were also put in place when dropping off with the T-11. Thereafter, only electronically supported withdrawal procedures are allowed until the end of further examinations. The reason for this is the greater susceptibility to wind of the non-rotating or controllable T-11 main canopy due to their cube shape.

Main screen T-11

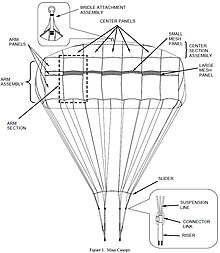

The T-11 is a non-steerable troop parachute with automatic opening by means of a pull-up cord and the replacement for the T-10 for combat jumps from low heights. The biggest obvious difference between the new T-11 and its predecessor and other troop parachutes is its large, cuboid-like construction. Its base is cross-shaped and resembles a cuboid due to the flat top and the side surfaces sewn together at the corners. The advantage of this design is a very stable sinking with low pendulum movements of the jumper. The fact that the air does not escape through an opening in the apex of the cap, but through the slits at the corners and five air-permeable sections on each side, promotes stability.

The main canopy is made of rip-stop nylon fabric with low air permeability and has a 28% larger surface area with a 14% larger diameter compared to the T-10. This additional material also leads to an increase in the weight of the entire jumping equipment to 24 kg. For this purpose, the soldiers with a maximum total weight of 181 kg can jump out of an aircraft flying at a maximum speed of 278 km / h and after a maximum load of 7 g with the parachute opening with less pendulum and at sea level a maximum of 5.64 m / s quickly sink to the ground.

A novelty with American automatic umbrellas is the use of a delay bag. The pull-up line continues to pull a packing bag out of the bag on the harness, whereby the suspension lines first stretch and the parachute then detaches from the packing bag, but then on the T-11 it is not the main canopy that opens, but an opening parachute. The 1.22 m large opening screen is attached to the outside of the delay bag and pulls it off the main canopy, which unfolds more slowly and with a smaller opening force. The delay bag and the opening screen remain connected to the main canopy by a line. This is no longer olive, but has got a gray color and is less visible against the sky.

The Teflon-coated suspension lines are comparatively short at 6.5 m in length and arranged in four groups of seven suspension lines each. As with modern wing parachutes, the T-11 also has a slider made of air-permeable fabric. The four groups of lines run through its corners from the base of the parachute to the harness. During the packing process, the slider is brought close to the base edge so that it limits the air attack surface of the parachute opening at the beginning of the opening process. While the canopy slowly fills with air, the slider (hence its name) slides down and the parachute unfolds completely. This reduces the opening force compared to the T-10, although the canopy area is significantly larger and the suspension lines are guided during the opening process, which reduces the risk of suspension lines being thrown over or twisting the suspension lines. The use of the delay bag and the slider extend the time until the parachute is fully deployed by two seconds, which corresponds to about six seconds when leaving an airplane and about eight seconds with a helicopter.

The pack cover for the main parachute is made of durable Cordura and is significantly more voluminous due to the larger parachute canopy. The large parachute canopy with the vertical sides can be driven off more easily because of the greater susceptibility to wind and increases the risk of the jumper being dragged along after landing. In order to prevent the latter, the parachute canopy is separated from the two main straps by the jumper using the canopy locks after landing in stronger winds.

Reserve umbrella T-11R

As a replacement for the Modified Improved Reserve Parachute System (MIRPS), the T-11R was introduced as a new reserve parachute for the T-11, MC-6 and MC-7 parachute systems as part of the ATPS program. The T-11R corresponds to the Low Level Reserve Parachute (LLRP) of the British armed forces and was developed by Irvin-GQ. Its multiconical design is pointed at the apex and is intended to ensure that the umbrella opens quickly and safely in all conditions. For this purpose, the umbrella was made as light as possible so that it unfolds even if the main umbrella is slightly damaged. The conical shape helps to prevent the reserve parachute from getting into the main canopy or its suspension lines and also avoids a suspension line throw-over more reliably than its predecessor. The top opening of the parachute canopy is closed with a tape at the beginning of the deployment process in order to keep as much air as possible for the opening in the parachute. Shortly before the parachute is fully deployed, the tape tears and reveals the opening in the apex, whereupon the air escaping through it reduces the deployment shock. At the beginning of the opening process, four pockets sewn on the outside of the upper parachute cover also fill with air. This part of the parachute immediately unfolds to its full diameter and no longer fits through the suspension lines of the possibly fully or partially unfolded main parachute.

A number of additional lines support the quick deployment of the reserve parachute even at low sink speeds. To do this, the additional lines connect the suspension lines to the parachute canopy just above the canopy edge, creating an air pocket along the edge of the parachute and promoting faster deployment to the full diameter. At low sink rates the auxiliary lines remain intact, while they are ripped apart by a strong opening shock due to a rapid sink. Nevertheless, with a fully deployed main parachute and a very low sink rate, an activated reserve parachute may not open. The jumper opens the reserve parachute by pulling on the central red handle. This releases a spring-loaded 1.8 m wide auxiliary parachute, which unfolds the reserve parachute without the jumper having to take any further action. At maximum jumping weight and speed, the glider opens in 0.7 s and then sinks to the ground at 7.9 m / s. With these characteristics, the T-11R is superior to the T-10R or MIRPS in all respects.

Harness

The harness developed as part of the ATPS program is used by the American armed forces for the T-11 and MC-6 jump parachutes. With the construction made of nylon, emphasis was placed on safety, comfort and adaptability. The harness can be adapted to the jumper at a total of nine points. Padding on the shoulder and leg straps provide a little more comfort when carrying the heavy, tight-fitting parachutes. Two D-rings can be used for all types of jumping baggage and weapon containers and two more triangular rings can be used for the drain line. The D-rings for the reserve parachute are located high above the canopy release locks on the shoulders to distribute the load when opening the reserve parachute, unlike the predecessor, in a way that is gentle on the spine along the longitudinal axis of the body. Two hook fasteners on the leg straps and a chest strap keep the jumper securely in the harness. The arrangement of the straps is chosen so that jumpers can jump with a tactical vest, protective vest or plate carrier on for the first time.

use

By 2016, the T-11 will replace all around 52,000 T-10s in the US Army. In the meantime, the Finnish and Australian military have also decided to procure the T-11. At the same time, the MC-6, with the same harness as the T-11 and the T-11R reserve parachute, replaces all parachutes of the MC1-1 series in the Australian and American armies. In the USA, the procurement of the MC-6 has now been completed after around 19,000 parachutes. The US Marine Corps also uses the T-11R reserve parachute in their newly introduced MC-7 parachute. After the US armed forces introduced a successor as the main user of the T-10 and MC1-1 parachutes, the many other users around the world will probably also look for alternatives and gradually discard these relics from the 50s.

After just a few thousand jumps with the T-11, the injury rate was more than halved compared to the T-10, regardless of the method of counting jump injuries. In 2010, soldiers jumped 42,304 times with a T-10 in nine months and were injured 116 times, which corresponds to an injury rate of 2,742 / 1000 jumps. During the same period, the T-11 jumped 9667 times, with only eleven soldiers injured and an injury rate of 1.137 / 1000 jumps.

Technical specifications

| Parameter | T-11 | T-11R |

|---|---|---|

| shape | Modified cross | Multi-conical |

| Parachute material | Nylon type IV, FG 504 | Nylon type IV, FG 504 |

| nominal diameter | 8.71 m | 8.84 m |

| Max jumping weight | 181 kg | 173 kg |

| Max. Opening speed | 278 km / h | 278 km / h |

| Sink speed with max. Jump weight | 5.6 m / s | 7.9 m / s |

| Max. Swing angle | 5 ° | 9 ° |

| Max. Opening load | 7 g | 11 g |

| Suspension lines | 28 | 20th |

| Line length | 6.5 m | 6.2 m |

| Packing cycle | 120 days | 365 days |

See also

- The MC-6 military parachute is the steerable round canopy parachute procured in parallel to the T-11 and uses the same harness and the same T-11R reserve parachute.

literature

- Headquarters, Department of the Army: Technical Manual for T-11 Personnel Parachute System , Washington DC, 2010

Web links

Individual evidence

- ^ Pfc. Eliamar Castanon: New Army Parachute Coming Soon. about.com, December 15, 2003, archived from the original on August 2, 2009 .

- ↑ US Army Public Health Command: Military Airborne Training Injuries And Injury Risk Factors , Aberdeen Proving Ground, Maryland, 2010 pp. 14ff

- ↑ Helmut Buch: History of the Airborne Troops , Weltbild Verlag, Augsburg, 2000 p. 96

- ↑ US Army Materiel Command, Natick Contracting Division . Retrieved December 8, 2012.

- ↑ ATPS in Global Security . Retrieved December 8, 2012.

- Jump ban with T-11R. (No longer available online.) Formerly in the original

- ↑ Validation of the reserve parachute T-11R. (No longer available online.) Formerly in the original

- ↑ Resumption of T-11 jumps in 2012 . Retrieved December 8, 2012.

- Jump ban with T-11 2011 Retrieved December 9, 2012.

- ↑ Headquarters, Department of the Army: Technical Manual for T-11 Personnel Parachute System , Washington DC, 2010 pp. 2-4

- ^ Headquarters, Department of the Army: Technical Manual for T-11 Personnel Parachute System , Washington DC, 2010 pp. 2–3

- ^ Headquarters, Department of the Army: Technical Manual for T-11 Personnel Parachute System , Washington DC, 2010 pp. 2–10ff

- ↑ Sam E. Middlebrooks: An Annotated Bibliography of MANPRINT-Related Assessments and Evaluations Conducted by the US Army, 2nd Edition: 1953 to 2009 - Volume III , Army Research Laboratory, Aberdeen Proving Ground 2010 p. 952

- ^ Headquarters, Department of the Army: Technical Manual for T-11 Personnel Parachute System , Washington DC, 2010 pp. 2-6f

- ^ T-11 in Special Operations Technology Magazine ( January 1, 2011 memento in the Internet Archive ). Retrieved December 9, 2012.

- ↑ Australia procures T-11 . Retrieved October 11, 2012.

- ^ Program Executive Office Soldier - Parachutes ( Memento of February 16, 2013 in the Internet Archive ). Retrieved December 8, 2012.

- ^ Headquarters, Department of the Army: Technical Manual for T-11 Personnel Parachute System , Washington DC, 2010 pp. 2–17ff