Vacuum adapter

The vacuum adapter is used for testing ( in-circuit test and function test ) of assembled circuit boards . It can be used as a single workstation as well as a production station (so-called inline ).

Structure and functionality

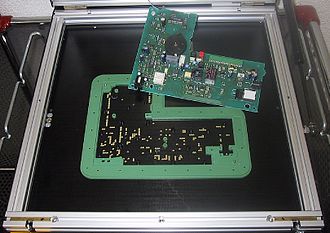

The circuit boards are placed on a test piece support plate, which is equipped with a sealing mask. Locating pins align the circuit board so that the spring contact pins hit the test surfaces cleanly. A vacuum is then generated via a vacuum pump , which presses the test item onto the spring contact pins. The green seal neatly seals the test item and the holes in the test item. The vacuum then sucks this test item together with the black base plate onto the contact pins.

If the test item has vias or other holes, a vacuum-free zone can be created at this point. In order to be able to generate sufficient contact force, the test item can be pressed to the spring contact pins with a hold-down stamp in addition to the vacuum.

Adapter specifications

The vacuum adapters have also evolved over the years, so that different systems can be bought on the market. The test item and the resulting contact accuracy and test point density determine the type of adapter required.

Conventional vacuum adapter

With the conventional vacuum adapter, the test object is pressed from commercially available spring contact pins by the vacuum. Due to the wobble play of the spring contact pins, the diameter of the test pads should, if possible, be greater than 0.8 mm, so that clean contact can still be guaranteed. Due to the test areas required, only pitches > 1 mm can be realized, which means that the test point density is rather low. Another disadvantage is the reduced service life of the spring contact pins due to the transverse forces that arise and the particle contamination when making contact.

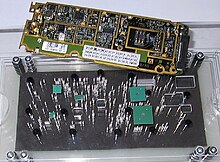

Rigid vacuum needle adapter

The rigid needle adapter is an independent, technically mature adapter concept. This enables contact to be made on the smallest contact points. The high test point density (up to 200 test points / cm²) ensures 100% testing of complex circuits. This technology extends the test area of the vacuum adapter up to contact pitches of> 0.4 mm and required test areas of 0.3 mm. The advantages are: The adaptations are very maintenance-free and the contact material can be easily exchanged in a few simple steps. The compact design of these adapters also guarantees a very long service life for the material and permanent stability of the tolerances.

Double-sided vacuum adapter

Both systems presented above can also be set up as double-sided contacting. The upper contact is pressed onto the test object with the vacuum, thus establishing a qualitative contact.

The interchangeable adapter

A change adapter with a vacuum mounting frame enables the use of several adapters in one system. As a result, only one specific adapter has to be produced for each test item, with which it can then be tested in the mounting frame. This also makes it possible to test the test items more cost-effectively.

Vacuum seal

A part-specific seal is required so that the circuit board can be properly sealed . In order to be able to produce such a seal, a casting mold must be milled in which the seal can then be cast. Antistatic rubber material is used so that the assemblies are not damaged by electrostatic discharge (ESD).