Emergency braking

With emergency brake is called in rail transport one of the monitoring devices in the train or in the control car or by a train control system initiated or caused by train separation and pressure drop rapid deceleration of a train . You can not with the driver in dangerous situations initiated emergency braking or by triggered by a passenger in a passenger train emergency braking be equated; however, they do not differ in their effects.

Emergency brakes are triggered by the safety systems listed below under certain conditions:

- Safety driving circuit (Sifa) (Germany)

- Sifa monitors the ability of the driver (Tf) to work alone in the driver's cab without an assistant. During the journey, the operator must release a foot or hand button and press it again at short time intervals, but no longer than every 30 seconds. If this operation is not performed, an indicator light lights up. If the operation is still not carried out, a warning tone or voice output will sound with a time-distance sifa after a distance of 75 meters or with a time-time sifa after 2.5 seconds. If the Sifa control elements are still not released and operated again, an emergency brake is applied in the case of a time-distance Sifa after a distance of 75 meters or 2.5 seconds for a time-time Sifa.

- Point train control (PZB) (Germany),

- The PZB monitors the observance of the signal orders valid for the train journey and, derived from this, the observance of different speeds or speed curves, but only if these signals are provided with corresponding PZB magnets. The exact behavior of the PZB (in the traction vehicle or control car) depends on the design of the vehicle equipment and its software version. A PZB emergency brake is triggered when the driver

- after driving past a pre-signal in the position Vr 0 / Ks 2 ( "expect stop") or Vr 2 ( "slow travel expect") a train control by the installed there 1000 Hz magnet obtained and not within four seconds vigilance operated - by pressing the alertness button, the driver confirms that the signal has been performed,

- after receiving a 1000 Hz influence, it does not go below a predetermined braking curve depending on the type of PZB train (with older designs, a test speed after a certain period of time). For example, a train (in this case with PZB90 V1.6 train type O) traveling at a speed of 160 km / h must have braked to less than 85 km / h within 23 seconds, which is continuously monitored using the braking curve .

- after the train has been influenced by a 500 Hz magnet, the prescribed maximum speed or the subsequent braking curve is exceeded,

- passes a main signal showing a stop with an effective 2000 Hz magnet without pressing the command button.

- exceeds the speed curve (or maximum speed) specified therein within the restrictive monitoring system .

- clearly exceeds the maximum speed specified for the PZB train type.

- In addition, disturbed track equipment can cause emergency braking if a magnet is put into the basic position by a disturbance and is thus effectively switched.

- Line train control (LZB) (Germany)

- LZB-guided trains are automatically braked if the driver significantly exceeds the target speed continuously specified by the system and signaled in the driver's cab. If the actual speed falls below the target speed again, the automatic braking is released automatically. In addition, emergency braking occurs on LZB-guided journeys if the "LZB end" warning before leaving the LZB guidance is not confirmed using the PZB-free button.

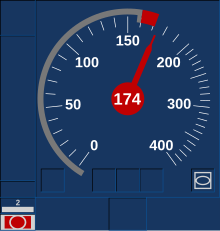

Driver's cab display of emergency braking (from 174 to 160 km / h) in the Driver Machine Interface (DMI) under ETCS ( Full Supervision mode )

- European Train Control System ( ETCS )

- ETCS-guided trains are automatically braked if the speed reaches the emergency break intervention curve or if there is a technical fault.

- Speed monitoring for NeiTech trains (GNT) (Germany)

- GNT-monitored trains are automatically braked if the driver exceeds the speed limits specified by the system and transmitted via EuroBalises or track coupling coils.

- Others

- Some of the systems mentioned above also trigger an emergency brake when their own malfunctions are detected (e.g. computer failure , transmission disruption) (and thus a failure on the safe side ).

- Depending on the locomotive, there are additional monitoring devices that can trigger an emergency brake, for example the over-speed protection of the transmission in diesel-hydraulic locomotives. This is also monitored on vehicles with a spring-loaded brake ( series 120 ): If the spring-loaded brake is applied while driving, an emergency brake is triggered.