Air Motion Transformer

The Air-Motion-Transformer ( AMT for short , also known as Heil- or Jet-Tweeter ) is a magnetostatic loudspeaker developed by Oskar Heil for reproducing high frequencies in the audible sound .

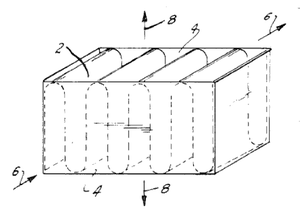

Meandering conductor tracks run on an accordion-like folded membrane, which is located in the magnetic field of a permanent magnet . When a signal is applied , an electric current flows through the conductor tracks, as a result of which a Lorentz force is exerted on the conductor tracks and thus on the membrane in the magnetic field . With a suitable arrangement, this force acts perpendicular to the membrane surfaces. The membrane folds open and close, which means that air is sucked in or pushed out. The big advantage over other ribbon tweeters is that in this way a multiple of the sound pressure is generated through transformation with comparatively little membrane movement.

Like any membrane loudspeaker, the Air-Motion-Transformer is a classic acoustic dipole . Due to the damping and encapsulation of the sound radiation from the rear, it can also be used in conventional multi-way loudspeaker constructions.

Air-Motion-Transformers are characterized by excellent impulse behavior and high efficiency due to the very small moving masses . The problem with the first Air-Motion-Transformer designs, some of which are still popular today, in which ferrite magnets were used in the magnetic drive, was usually a high total weight and a considerable size, since the magnetic fields in the relatively large air gap require strong permanent magnets, but this is newer Structural shapes could be overcome through the use of highly coercive neodymium magnets. Although the membrane membrane is exposed to strong mechanical and electrical loads at high sound pressures, the resilience of the Air-Motion-Transformer is not lower than that of other sound transducers if, instead of the polyamide or polyester ( Mylar ) membrane materials used previously, modern membrane materials made of polyimide ( Kapton ) and sophisticated adhesive technologies are used.

Air-motion transformers are used in particular in studio and hi-fi speakers as tweeters in the frequency range from around 1.5 kHz to over 20 kHz.

Loudspeakers based on this principle were or are being made by the German companies ADAM, Burmester , ELAC , ETON, EVE Audio, HEDD, MUNDORF, MBHO, the Swiss company PRECIDE, the Danish loudspeaker manufacturer AUDIOVECTOR, the Spanish company BEYMA and the companies ESS (USA ) and FAL - Furuyama Audio Labs - (Japan).