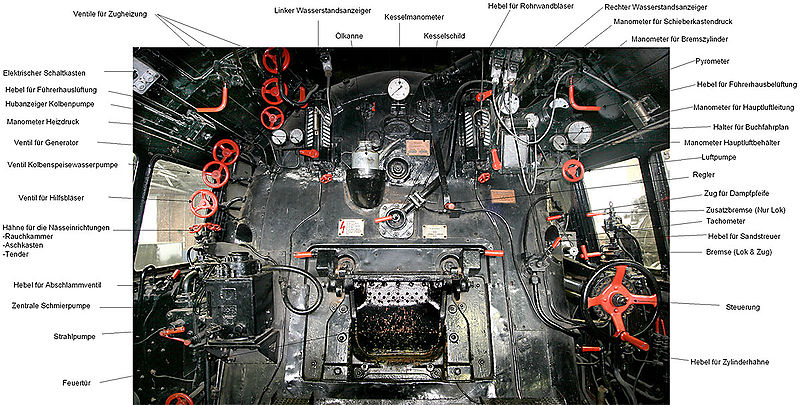

Controls of a steam locomotive

This article explains the controls in the driver's cab of steam locomotives . The controls listed differ depending on the type of locomotive.

Controls

Operator controls of the train driver

- Regulator

- The regulator (also called regulator) is usually a large, axially rotatable lever, dominating in the middle on the boiler wall, with side-pull regulators on the side next to the standing boiler. It opens the valve in the steam dome to supply the cylinders and thus represents the locomotive's "throttle lever", with which the steam pressure in the valve body is controlled. In the technical sense, it is not a regulator because it does not automatically react to changed pressure conditions.

- control

- Typically a handwheel or crank on the driver's side. The control determines the opening times of the slides and thus the amount of steam entering the cylinder, also known as the filling. When starting up, the maximum filling is used, so the maximum torque is available, but the machine also works with maximum steam consumption. The controller can be a gearshift compare, since about standing on the drive wheels available torque can be changed.

However, steam engines are more elastic than internal combustion engines and do not need a gear reduction because they are able to start up under load. However, if the cylinders are filled to capacity at high speed and low load, this means unnecessarily high steam and fuel consumption. Instead, the control is then set to shortened filling times: the filling of the cylinders is ended long before dead center and the steam can continue to expand in the cylinder. The direction of travel can also be reversed via the control. - Additional brake valve or additional brake valve

- With the additional brake, the air pressure in the brake cylinders of the locomotive is controlled independently of the rest of the train. The additional brake valve is a three-way valve with three positions. In the filling position, the brake cylinder is filled with compressed air, in the final position the brake cylinder is locked - air can neither enter nor escape - and in the release position the brake cylinder is connected to the free air and is therefore depressurized. An additional brake valve fulfills the same task, but has a similar structure to a driver's brake valve.

- Driver's brake valve

- The driver's brake valve controls the air pressure in the main brake line of the train. The driver's brake valve is usually a rotary slide valve . It has several intermediate positions compared to the additional brake valve. In the operating position, for example, the air pressure in the brake line is automatically adjusted if compressed air is lost due to small leaks; the quick braking position is used to make the brake respond as quickly as possible in order to achieve a short braking distance.

- Cylinder valve train

- The valves attached to each working area of the steam cylinder are operated with the cylinder valve train. When the machine is not at operating temperature, these are opened to allow condensation to drain off. They can also be used to preheat the cylinders by slightly opening the regulator with the cylinder valves open and the brakes on, allowing some steam to flow through the cylinders. When the cylinders are at operating temperature, the cylinder taps are closed. But they can be opened while driving, if z. As water is taken out of the kettle and thereby water hammer threatening.

- light switch

- Line lights of the locomotive, engine lights and cab lighting.

- PZB / Indusi

- Control panel for punctual train control ( PZB ), colloquially also called inductive train protection ( Indusi ).

- Pipe train

- The steam whistle of the locomotive is operated with the whistle .

- Chime

- A bell must be available on locomotives traveling on routes with unsecured level crossings. This is operated with steam in older locomotives and with compressed air in newer ones.

Controls of the heater

In the case of locomotives with stoker or oil firing, the heater - which also has to do a lot of maintenance work - was not dispensed with; he was then responsible for the operation of:

- Fire flap or fire door

- Coals are shoveled through this opening onto the grate of the fire box . So that the fire door is not open unnecessarily long, the flap can often be opened with a pedal when shoveling .

- Steam jet pump

- The steam jet pump is a pump driven by steam pressure, which pumps water from the tender against the boiler pressure into the boiler.

- Adjusting valve for piston pump

- The piston feed pump is started with the adjusting valve and its delivery rate is controlled.

- Steam heating valve

- With the steam heating valve, the heater controls the amount of steam or the pressure in the heating steam line via which the attached train is heated.

- Auxiliary blower

- When the locomotive is delivering power, i.e. the regulator is open, the induced draft is generated by the exhaust steam from the machine. The induced draft can be generated with the auxiliary blower at standstill or with the controller closed. This is especially important if the heater wants to add coal when the regulator is closed or when it is at a standstill, as otherwise a so-called flashback can occur. Such flashbacks are very dangerous and can cause fatal injuries to the heater.

- During show trips with historical steam locomotives, experienced stokers operate the auxiliary blower in order to generate clouds of smoke from the chimney when entering train stations, despite the closed regulator for trainspotters .

- Valve for ash box, smoke box and coal syringe

- With this valve, water that is conveyed out of the tender by the feed pumps can be used to extinguish embers in the ash pan and the smoke chamber and to wet coal on the tender.

- Blowdown valve

- The blow-down valve itself is located on the front of the tank at the lowest point, but it is operated from the driver's cab while driving. The blow-down valve is opened regularly for a few seconds while the boiler is under pressure in order to let the sludge and scale out of the boiler before it solidifies.

- Lubrication pump

- The lubrication pump supplies parts of the steam engine centrally with oil. Several lubrication points are connected to the lubrication pump and the oil quantity can be individually regulated. In addition, it can be checked whether a lubrication point is even getting oil.

- Adjustment valve for the turbo generator

- In locomotives with electric lighting, the electricity is generated using a steam-powered turbo generator. With the adjusting valve, the generator is only put into operation or switched off; the generator regulates the speed of the generator automatically via a centrifugal governor.

Display elements

Display elements of the train driver

- Boiler pressure

- Valve body pressure

- Boiler water levels

- Speedometer

- Main air reservoir pressure

- Main air line pressure

- Air pressure brake cylinder

Display elements of the heater

- Boiler pressure

- Boiler water levels

- Tender water level indicator

- Tender oil level (with oil firing)

- Heating pressure meter

- Piston feed pump stroke indicator

Control elements on locomotives with special equipment

- Condensing tender

- For locomotives with a condensation tender , the heater has two diverting valves. With one valve he can divert the machine exhaust steam past the induced draft turbine in the smoke chamber in order to change the fire fanning. The other valve is used to direct steam past the turbines for the cooling fans in the tender in order to regulate the cooling capacity or the condensate temperature.

- Stoker firing

- Large coal-fired steam locomotives (such as the Big Boy ) would have overwhelmed any stoker when shoveling. They therefore had a conveyor system (usually a screw conveyor) called a stoker , which was driven by steam pressure. The heater then had to at least regulate the flow rate and - using mechanical distributor blades or by hand - ensure optimal distribution of the coal over the grate surface.

- Oil burner

- In the case of oil firing, the oil was mostly atomized by steam pressure. The heater gets some additional controls for this:

The oil slide, a hand wheel with which he can control the amount of oil that gravity flows into the burners from the tender. Each burner (usually there are two) has its own valve with which the atomizer steam is adjusted.

literature

- Leopold Niederstrasser: Guide for the steam locomotive service . ISBN 3-921700-26-4

- Author collective: The steam locomotive . Transpress, ISBN 3-344-70791-4