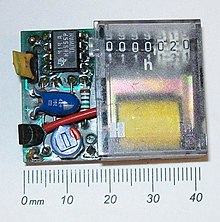

Operating hours counter

An operating hours meter ( English Hobbs meter ) is an electrical measuring device for the cumulative measurement of operating hours , the time that a device or an electrical consumer is in operation.

Control cabinets and systems

Typical electromechanical hour counters work here on the 230 V alternating current network (50 Hz or 60 Hz) and use, for example, the practically constant network frequency to drive a counter with a synchronous motor . They show the total elapsed time in hours and have a resolution of 0.01 to 1 hour.

Hour counters with stepping mechanisms and a timer are also used for operation with DC voltage. Electronic operating hours counters have a quartz oscillator as a timer and an electronic circuit for realizing the counter, for example a synchronous counter, the counter reading of which is retained in the memory by a buffer battery even in the event of an interruption in operation .

Mercury coulometer

For small devices, there were historical designs of operating hours counters in which a mercury droplet apparently migrates in a capillary due to the constant current flow that is present during operation . In fact, however, metallic mercury goes into solution on one side of the droplet, while it is newly deposited out of solution on the other side. This causes the drop to move slowly and depending on the strength of the current. Strictly speaking, it is not the mercury droplet that moves, but the electrolyte space between the two mercury columns. This narrow space is also the “pointer” of the measuring tube. When the gap has reached one end of the measuring tube, it is "at the end" and can no longer be used. However, if the direction of flow is reversed in good time before the end, the measuring tube must continue to be used in the opposite direction. Due to the mercury content, these hour meters are practically no longer used and represent a disposal problem due to their small size and the previously often deliberately hidden application in electronic devices.

aviation

In aviation, the operating hours counter ( also called Hobbsmeter after the John W. Hobbs Corporation founded in 1938 ) is used in aircraft to determine the operating time of the engine. This results in the maintenance intervals for aircraft maintenance and, for example, the rental time.

Older operating hours counters for aircraft had a kind of clockwork with hands to indicate the hour. Digit displays are common today. In addition, a flight hour counter can be attached, which is triggered by aerodynamic forces on the wing leading edge. The flight hour meter is often used as a calculation basis for aircraft rentals.

The tach timer counts the engine revolutions (divided by the nominal speed) and is used to determine load-adjusted engine maintenance intervals (e.g. oil change). Hard Time only calculates the actual flight time.

Since the operating time of an internal combustion engine block is often measured - from starting the engine until it is switched off, which is particularly important when flying a motor glider - we speak of block hours . This hour is divided by counting wheels with 10 digits each or with a scale from 0–9 decimal, mostly at least and mostly into 10 tenths of an hour , which is colloquially interpreted as 100 block minutes . Such a block minute corresponds to 1/100 of an hour and thus 36 seconds.

Agricultural machines and construction machines

These use an operating hours counter that either begins to count when the ignition is switched on or is connected to terminal D + of the alternator and only begins to count when the engine is running. The mileage would not be a favorable measure of power output due to the graduated working speeds.

Web links

Individual evidence

- ↑ Heinrich Mensen: Handbuch der Luftfahrt , VDI book, 2013. Chapter 39.5.1 Preventive maintenance, p. 1351. Retrieved on August 16, 2015.

- ^ Akaflieg Graz: powered flight. Training and costs, 2015. Price list for motor gliding, accessed on August 16, 2015.