6 pounder field cannon C / 61

| 6 pounder field cannon C / 61 | |

|---|---|

| General Information | |

| Military designation: | 6 pounder field gun C / 61 |

| Manufacturer country: | Kingdom of Prussia |

| Developer / Manufacturer: | The pipe came from Krupp. Everything else was the delivery and manufacture of the Spandau artillery workshop. |

| Development year: | around 1857 |

| Production time: | around 1860 to 1864 |

| Weapon Category: | Field cannon |

| Technical specifications | |

| Pipe length: | 78 pruss. Inch = 2.04 m |

| Caliber : |

3.5 prussia. Inch = 9.15 cm |

| Number of trains : | 18 parallel trains |

| Furnishing | |

| Closure Type : | simple piston lock |

| Ammunition supply: | manual, breech loader |

The 6-pounder field cannon C / 61 was one of the first breech- loading guns with rifled barrel in the Prussian army . The C / 61 series included 6-, 12- and 24-pound cannons. The field artillery was assigned the 6-pounder as the first gun with a cast steel barrel, while the 12- and 24-pounder belonged to the siege and fortress artillery.

The 6 pounder had a caliber of 9.15 cm. The correct name for this gun was “drawn. Cast steel 6pfdr. with piston lock " . In 1871, as part of a reorganization, the type designation was changed to “9cm steel cannon with piston lock” .

It was the predecessor of the 6 pounder field cannon C / 64 .

history

Historically, the breech loading guns are the successors of the medieval chamber pieces (chamber loader cannons). There were repeated attempts to make breech loading cannons. However, these attempts essentially failed due to technical problems. Around 1840, the Swedish manufacturer Martin von Wahrendorff tried again to make breech-loading guns marketable. He started with smooth breech-loaders. He used a piston lock as a breech and full leaded bullets as projectiles.

In 1843 Prussia also began to experiment. These were carried out with smooth 6-, 12- and 24-pound cannons from Wahrendoff's construction. These cannons already had an improved breech block.

Based on the experiences that had been made in the meantime with rifled infantry weapons using long projectiles, Wahrendorff was encouraged by the Italian Cavalli in 1846 to equip his cannons with rifles as well. He also now used lead long bullets.

In the meantime, Prussia had also come to the conclusion that the increased performance of the infantry weapons would also require an increase in the performance of the guns. On the basis of this finding, Se. Royal The Highness Prince Adalbert of Prussia commissioned the Artillery Examination Commission (APK) on February 20, 1850 to give an expert opinion on this.

This date is to be regarded as the hour of birth of modern Prussian artillery. After much discussion, the APK then decided to use the Wahrendorff system as the basis for further development. The concrete experiments began in 1851. The tests were carried out initially with pipes made of cast iron and later of bronze. However, both materials proved unsuitable for use in rifled guns. Based on experiences that had already been made with Krupp cast steel tubes, two cast steel blocks were ordered in 1855 for the production of drawn 6 pounder breech-loading cannons. Krupp only supplied the blanks for this. The final processing took place in the artillery workshops in Spandau. In the subsequent shooting tests, this variant was found to be very suitable.

In May 1857, Major v. Wedell created a memorandum in which he tried to demonstrate the need to introduce a rifled six-pounder as an equivalent to the rifled infantry weapons. August Encke, the head of the APK at the time, was not entirely convinced of this idea. He wanted to replace the previous smooth six-pounder made of bronze with a new, short twelve-pounder, as he believed that this gun could better meet field requirements. This gun was actually introduced on March 10, 1859 and remained in existence until the end of 1866.

The experiments with the rifled six-pounder continued, however, and so it came about that during a test shooting on May 7, 1859, the then Prince Regent Wilhelm ordered the immediate procurement of 300 six-pounder guns. The pipe blanks were supplied by Krupp. The mechanical processing was carried out by the companies Wöhlert and Schwarzkopf in Berlin.

As early as January 1860, the rifled cast steel 6-pounder was introduced by means of the Highest Cabinet Order in such a way that every artillery regiment had to convert three 12-pound batteries into 6-pounders.

This conversion took place during the summer of 1860.

The then chairman of the artillery examination commission , August Encke, made a special contribution to the introduction of the Krupp cannon barrels . After him, in recognition of his achievements, the previous Magdeburg Foot Artillery Regiment No. 4 was renamed "Foot Artillery Regiment Encke (Magdeburgisches) No. 4".

The new guns were labeled “pulled. Cast steel 6pfdr. with piston lock ”introduced into the Prussian army. The addition "C / 61" as a classification feature was added at a later date.

technical description

From a technical point of view, the C / 61 series was a further development of the medieval chamber loader cannons. Similar to these, they were also loaded from behind. The original idea of Wahrendorff was that he wanted to create a type of gun that would be easier to use in the cramped conditions of ships or casemates. Another reason after 1846 was that it was impossible to load the leaded long projectiles from the front. In other European countries, however, a different approach was taken by using drawn muzzle-loaders with a different bullet shape (see the La Hitte system ).

The pipe

The tube was made of cast steel and, in its original construction, was cylindrical at the rear over approx. 3/4 of its length and then tapered conically towards the front. The end was formed by a frieze in the mouth, which was connected to the tubular body with a groove. At the point where the transverse hole for the closure was made in the pipe, reinforcements were attached to both sides of the pipe. Approximately in the middle of the tube were the so-called shield pins on both sides with which the tube was mounted in the carriage. At the transition between the trunnion and the tube there were additional reinforcements that had the task of fixing the tube in the mount. The ignition hole stood with its axis; Approximately 1/4 "in diameter approximately 1.6" from the front face of the locking piston. The pipe was equipped with 18 parallel pulls.

The closure

The so-called Wahrendorff piston closure was used as the closure . This consisted of the locking piston made of wrought iron, the transverse cylinder made of cast steel, the locking door made of bronze and the crank. The crank of the clamping screw of the locking piston was secured with two nuts in this first series use. In later versions, these nuts were replaced by an iron split pin. To obturator cup-shaped pressboard discs were used, which had been fixed to the 6-pounder with the cartridges.

The mount

The C 42/56 construction was used as the carriage . The designation C 56/61 can also be found in the literature. The mounts were made according to the Prussian wall mount system. With this system, the walls are parallel and evenly thick. In this system, they were kept at a distance by three bars (forehead, middle and tail bars). The upper edge of the carriage walls was broken twice and divided the carriage into breast, middle and tail pieces. The lower edge of the carriage walls was straight and only rounded like a slide at the tail end in order to allow easier gliding when returning. The walls were uniformly 2.65 inches (about 6.95 cm) thick with a height of 12.9 inches (about 33.75 cm) in the chest piece. The clearance between the carriage walls was 9.05 inches (approx. 23.7 cm). The walls had cutouts for the trunnion bearings and the axle chuck as well as wall openings for the pins of the bolts and the alignment shaft bearings. To stabilize the carriage walls were girded with three side bands. A shaft straightening machine was integrated into the mount. This consisted of a wrought iron straightening shaft, the straightening screw, the straightening base and the crank with the adjusting nut. The straightening shaft was pivoted in the walls. The wrought iron axle was attached to the walls by means of a wooden axle lining. In addition to the left wall of the mount, a so-called axle box made of sheet iron was attached to the axle lining, which was intended to accommodate smaller gun accessories. The wheels were ordinary wooden wheels and, including the tire, had a diameter of 58 inches (approx. 151 cm). The storage height, d. i.e. the distance between the installation surface and the center of the trunnions was 41.4 inches (approx. 109 cm)

The limber

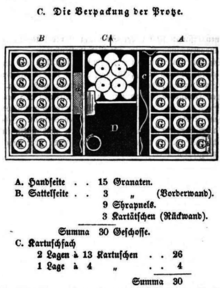

As Protze the material C42 / was also used 56th The designation C 56/61 is also found here in the literature. The limber consisted essentially of the limber frame, the wrought-iron axle in a wooden axle liner, the two wheels, the wheel diameter was 47.50 inches (approx. 124 cm) including the tire. The drawbar, the fixed rear bracket for the pole horses (the middle horses were tied to a movable front bracket) and the limber box as well as a number of necessary fittings. The swank box was set up to hold 30 storeys in wooden bullet boxes. The complete equipment, but without the required gun accessories, can be found in the inserted table.

| designation | piece |

|---|---|

| Grenade with bolt capsule and mouth screw |

18th |

| Shrapnel with bolt capsule and mouth screw |

9 |

| Grapeshot | 3 |

| 1.2 pound cartridge with particle board bottom |

30th |

| 0.5 pound cartridge with no pressboard bottom |

4th |

| 0.25 pound cartridge with no particle board bottom |

4th |

| Pressboard floor | 8th |

| Pin | 33 |

| Ignition screw | 34 |

| Pin bolt | 5 |

| Bolt caps | 5 |

| Beater tubes | 33 |

The connection between the mount and limber was made according to the so-called balancing system. In this system, the connection is at a greater distance behind the front axle. The steering angle was 85 °. With the front bracket attached, the drawbar was lowered by 16 °. Without the front bracket, the drawbar rose 26 °.

This gun, which by and large had proven to be quite functional and suitable for war, remained in the field artillery until after 1870. Later it was used in the fortress artillery. A complete redesign of this type took place with the material C / 64 .

The charging process

The 6-pounder was loaded as follows:

- Loosen the rear tensioning screw

- Pull out the cross cylinder to the right

- Pull out the locking piston and open the locking door to the left

- Wiping and greasing the pipe

- Insertion of the lead shirt grenade after the gun leader had inserted the pin and the ignition screw into the grenade or shrapnel.

- Insert the cartridge.

- Close the lock door and push the lock piston forward (the powder bag and grenade are moved forward with it, the powder charge comes to lie under the ignition hole).

- Insertion of the cross cylinder

- Fix the locking piston and the transverse cylinder in a force-locking manner using the rear clamping screw

- Insertion of the hammer tube (friction ignition screw) into the ignition hole

The gun is now ready to fire.

Technical specifications

The numerical values of the Prussian order of measures and weights of May 16, 1816 were used as the basis for converting the length measurements. 1 Prussian inch = 2.615 cm. 1 step = 2.4 feet (approx. 75.33 cm). The weights were converted in accordance with the Prussian law of May 17, 1856 (1 Prussian pound (inch pound) = 500 g or 30 lots of 16.67 g each).

pipe

- Caliber: diameter of the soul 3.5 Prussian inches = 9.15 cm

- Pipe length: length of the entire pipe 78 Prussian inches = 2.04 m. Length of the drawn part 59 Prussian inches = 1.54 m. Length of the line of sight 77 Prussian inches = 2.014 m

- Trains: The 6 pounder had 18 parallel trains. The width was 0.40 inches (10.5 mm) by a depth of 0.05 inches (1.3 mm). The panels were 0.20 inches (5.25 mm) wide. The twist length was 15 feet (4.70 m) with a twist angle of 3 ° 30 '

- Weight without lock approx. 409 kg

- Weight with lock approx. 433 kg.

Mount

- Elevation range: −8½ / + 17 °

- Directional range: 0 ° (the entire gun was aimed)

- Weight of the empty carriage, without tube approx. 533 kg

- Weight of the equipped carriage, without pipes approx. 566 kg

Limber

- Weight of the empty limber approx. 475 kg.

- Weight of the equipped limber approx. 785 kg

gun

- Weight of the armed gun without crew approx. 1700 kg

Ammunition type / weight as of 1861:

After the rifled guns were introduced, the ammunition had to be adapted accordingly for this type of gun. In analogy to the projectiles of the smooth guns, grenades, incendiary grenades, shrapnel and grapeshots were also provided for the rifled guns. The construction of the grenades did not cause much difficulty and was completed in the spring of 1859. At the time, the ignition device used was the C 61 percussion fuse, developed by Rudolf Sylvius von Neumann in 1859, because it was also known as the Neumann fuse:

It consisted of the following parts.

- The bolt capsule "e" made of sheet brass. This had a beaded edge with which it rested on a heel in the mouth hole. Below it had a double floor, which was broken through for the so-called burn hole. To prevent explosives from entering the bolt capsule, the fire hole was closed with a Cambrai plate (Cambrai / Kambray or chamber cloth was a fine cotton fabric) inserted in the double floor.

- The massive brass impact body "c". This was drilled through lengthways in the center (the ignition channel) and carried the ignition needle made of sheet brass at the top.

- The mouth screw "a" made of iron and copper-plated to protect against rusting, which was provided with two recesses for a socket wrench to make it easier to screw in.

- The ignition screw "b" made from measurement, in which a primer with the associated igniter was attached. A fuming mercury mixture was used for ignition.

- The so-called linchpin "d" made of spring-hard steel. Its task was to prevent the impact body from jumping forward during transport or loading and thus causing the explosive charge to explode prematurely.

How it works: Before the contactor is charged, i. H. When the projectile was inserted into the barrel, the linch pin was inserted into the projectile and then the ignition screw was screwed in. After firing and as soon as the projectile had left the barrel, the projectile was ejected by rotating the projectile around the longitudinal axis in which the projectile had been moved by the pulls. The bullet was now in focus. When the projectile hit an obstacle and the associated reduction in speed caused the impact body (needle bolt) to jump forward, which then caused the detonator to explode with its detonating needle. The resulting jet of fire hit the explosive charge of the projectile through the ignition channel and caused it to explode. The bolt capsule, the needle bolt and the mouth screw were already pre-assembled from the ignition device. In the battle, only the pin and the ignition screw were still inserted into the projectile.

It looked a little different for the construction of the shrapnel. Since the previous flame fuses (time fuses) were not suitable for breech-loaders with pressed projectile guidance, the percussion fuses of the grenades were also used for this. This was a concession to those in the artillery who believed that shrapnel was indispensable in artillery combat. It was similar with the grapes. In the end, these too were only introduced or retained with consideration for opinions within the artillery.

grenade

The grenade (called the lead shirt grenade) consists of: Iron core about 7.06 inches (18.50 cm) long and about 7.5 pounds in weight. The iron core was provided with 4 hoops and these were interrupted with 2 longitudinal cutouts. These had the task of fixing the lead jacket in its position. The thick lead jacket weighs approx. 5.5 pounds, the explosive charge approx. 15 solder (approx. 250 gr.) Gun powder and the ignition device C 61. The bolt caps, needle bolts and mouth screws were already pre-assembled from this. Total weight: 13 3/4 Prussian. Pound = 6.875 kg.

Incendiary grenade

These are the normal grenades which were also filled with 6 fires. The incendiary grenades were only carried in the ammunition wagons. Detonator like the grenade.

shrapnel

Outwardly, the iron core had the same shape and dimensions as the grenade. However, it had thinner walls, so that it had a larger free space, weight about 6.25 pounds. The lead jacket was like the grenade, weight about 5.5 pounds. The filling consisted of 88-92 lead cavalry balls, which were fixed by a sulfur pouring. Weight of the stuffed shrapnel approximately 15.5 pounds. In addition, there was the explosive charge, approx. 12 solder (20 g) gun powder, which was filled into a tube to prevent it from mixing with the sulfur pouring. The loaded shrapnel weighed approximately 15.75 pounds. Ignition device: Since at the time of introduction there was still no fully functional time fuse, the existing Richter time fuse was not suitable for the field artillery, the shrapnel was also equipped with a C 61 percussion fuse. As this solution was unsatisfactory, the use of shrapnel in the field artillery was discontinued in 1866

Grapes

The grapes consisted of a tin can about 7.7 inches (about 20.15 cm) long and a filling consisting of 41 zinc balls, each weighing 5 solder (about 83 g). The ball filling weighed about 6 pounds 20 solder (6.65 pounds) and the compl. Grape approximately 9 pounds = 4.5 kg.

charge

The usual utility charge consisted of 0.6 kg of Prussian gun powder in a cartridge pouch. Cartridges with a weight of 0.5 or 0.3 pounds were still available for the so-called high bow shot.

- Ignition: Over-ignition by a beater

- Muzzle velocity: The muzzle velocity is directly dependent on the cargo used. For this type of gun, 1/11 bullet weight was specified as the largest charge. Under these conditions the muzzle velocity was 1056 preuss. Foot = 331.40 m / s.

Firing range (working range)

- Grenade: Against smaller troop formations up to approx. 2500 paces (approx. 1875 m); against larger troop units and localities up to approx. 5000 paces (approx. 3750 m).

- The range of use for the high bow shot with a 0.3 pound charge was approx. 600–1200 paces (approx. 450–900 m) and for a charge with 0.5 pound (approx. 750–1500 m)

- Shrapnel: Up to approx. 2000 steps (approx. 1500 m).

- Grape: up to approx. 400 steps (approx. 300 m).

literature

- Brockhaus Konversations-Lexikon. 14th edition. Volume 7 from 1894 to 1896. Keyword: Gun

- Meyers Konversations-Lexikon. 4th edition. Volume 7 from 1885 to 1892. Keyword: Gun

- W. Witte: The rifled field guns C / 61, C / 64 and C / 64/67. 3. Edition. Ernst Siegfried Mittler and Son, Berlin 1867. (Here: reprint by J. Olmes, Krefeld 1971)

- H. Müller: The development of the field artillery from 1815 to 1870. 2nd edition. Berlin 1893.

- Max Köhler: The Rise of Artillery to the Great War. Barbara-Verlag Hugo Meiler, Munich 1938.

- Diedrich Baedecker: Alfred Krupp and the development of the cast steel factory in Essen. GD Baedecker, Essen 1889.

- Josef Schmölzl: Supplementary weapon theory. 2nd Edition. Literary and artistic establishment of the IGGolla'schen Buchhandlung, Munich 1857.

- Taubert: The historical development of the Prussian system of rifled guns. In: Archives for the officers of the royal Prussian artillery. Volume 61, Ernst Mittler and Son, Berlin 1867.

- J. Schott: Outline of the weapon theory. Eduard Zernin, Darmstadt / Leipzig 1868.

Individual evidence

- ^ Army Ordinance Sheet. 5th year, No. 18 of August 14, 1871, p. 195. Ed. War Ministry Berlin, Verlag Mittler und Sohn Berlin. (The spellings correspond to the spelling of the time.)

- ↑ Josef Schmölzl: Supplementary weapon theory. 2nd Edition. Verlag Literarisch-Artistische Anstalt der IGGolla'schen Buchhandlung, Munich 1857, p. 225. reader.digitale-sammlungen.de

- ^ Taubert: The historical development of the Prussian system of rifled guns. In: Archives for the officers of the royal Prussian artillery. Volume 61, Verlag Ernst Mittler and Son, Berlin 1867, p. 223.

- ^ Taubert: The historical development of the Prussian system of rifled guns. In: Archives for the officers of the royal Prussian artillery. Volume 61, Verlag Ernst Mittler and Son, Berlin 1867, pp. 225–237.

- ↑ Diedrich Baedecker: Alfred Krupp and the development of the cast steel factory in Essen. Verlag GD Baedecker, Essen 1889, p. 39.

- ↑ Diedrich Baedecker: Alfred Krupp and the development of the cast steel factory in Essen. Verlag GD Baedecker, Essen 1889, pp. 44–45.

- ^ Taubert: The historical development of the Prussian system of rifled guns. In: Archives for the officers of the royal Prussian artillery. Volume 61, Ernst Siegfried Mittler and Son, Berlin 1867, p. 242.

- ^ H. von Müller: The development of the field artillery. Published by Robert Oppenheim, Berlin 1873, p. 170. Reprint. Salzwasser Verlag GmbH, Paderborn. ISBN 978-3-8460-3766-9 .

- ↑ W.Witte: The solid field guns C / 61, C / 64 and C / 64/67 standards. 3. Edition. Ernst Siegfried Mittler and Son, Berlin 1867. Reprinted here in J. Olmes, Krefeld 1971, p. XXI.

- ↑ There are many different ways of writing this in contemporary literature.

- ↑ W. Hoffmann: The elements of the weapon theory. Published by A. Bath, Berlin 1860, p. 77.

- ↑ J. Schott: Plan of the weapon theory. Eduard Zernin, Darmstadt / Leipzig 1868, p. 99.

- ^ Hoffmann (Captain a la suite of the 4th Artillery Brigade): The field gunner . Publishers of the Vossische Buchhandlung. Berlin 1865, p. 121.

- ^ Karl Theodor von Sauer: Outline of the weapon theory. Literary and artistic establishment of the IG Golla'schen Buchhandlung, Munich 1869, p. 350.

- ↑ H. von Müller: The development of the field artillery. Published by Robert Oppenheim, Berlin 1873, pp. 171–173. Reprint: Salzwasser Verlag GmbH Paderborn. ISBN 978-3-8460-3766-9 .

- ↑ Guide to teaching about the rifled artillery and their treatment for the NCOs of the Königl. Prussia. Artillery. Verlag der Vossischen Assortments-Buchhandlung, Berlin 1861, 2nd edition, pp. 8-13.

- ↑ Martin Prehm: The artillery shooting art from Prussian rifled guns. Vossische Buchhandlung, Berlin 1867, p. 152/53.

- ↑ Arkosay: The Tactics of the Modern Age from the Standpoint of the Century and Science. Eduard Zernin's publisher, Darmstadt / Leipzig 1868, p. 241.