CMT welding

CMT-welding (of English cold metal transfer ) is a gas metal arc welding process .

The process, which has been used since 2005, was developed by the Austrian welding technology company Fronius and is one of the arc welding processes . It is a further development of MIG / MAG welding with a new method of droplet detachment and is used, among other things, to produce mixed joints of galvanized steel and aluminum . The welding process can also be used for spatter-free soldering of coated metal sheets and thin sheet metal connections (≤1 mm).

In addition to a pulsating welding current (pulse welding), this method also moves the welding wire back and forth at a high frequency. This is processor-controlled and can be adjusted according to the prevailing conditions.

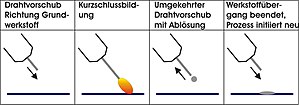

During the process, the live welding wire is moved towards the base material until a short circuit is formed. After the current flow has been set, the power supply is interrupted under computer control and the welding wire is moved back in the opposite direction. The movement of the wire causes the welding beads that form during a short circuit to detach from the wire particularly easily. There are only a few splashes.

Due to the regulated power supply and the supporting effect of the wire movement during the material transfer, there is only a very low heat input to the base material. The advantages of this are a small heat-affected zone and very little dilution (mixtures of filler metal and base material).

Web links

- TU Brandenburg: Areas of application, processes, advantages of CMT welding ( Memento from March 4, 2016 in the Internet Archive )

- Fronius welding processes - Cold Metal Transfer

Individual evidence

- ↑ Gerd Trommer, Andreas Nitsch CMT welding. A new welding process, CMT, has been in use for 3 years . In: Konstruktionspraxis. June 11, 2008, accessed November 16, 2014.