Chemical logistics

The chemical logistics is a specialized field of logistics , dealing with the specifics of the logistical handling of chemicals involved. It includes the planning, control and optimization of the transport and storage of chemicals. A special case is the handling of hazardous substances , whose special requirements for safety and compliance with regulations result in special logistics concepts.

Development of chemical logistics

Chemical companies operated their own logistics, such as storage and transport, for a long time, as there are high demands on staff and equipment. Today (2018) outsourcing to those logistic service providers, who themselves consist of sold shares of the chemical companies, are the rule. The chemical industry was able to achieve a sales increase of 20% in 2010. Chemicals are used in more and more areas, preferably in industry. In order to satisfy consumer demand and to be able to take into account the special features that chemicals bring with them, a separate branch of logistics has been developed, chemical logistics.

Differentiation from conventional logistics

What distinguishes chemical logistics from other logistics are the characteristics that both organic and inorganic chemicals bring with them. Transport, storage and transshipment are the areas into which logistics are divided. In chemical logistics, the sub-areas pay particular attention to the fact that the most diverse types of hazardous substances are involved. A degree of security and control must be reliably guaranteed. This shifts the weighting on behalf of logistics: the six-R rule .

Chemical logistics tasks

The logistical mandate (the six-R rule ) is to provide the right amount of the right objects in the right place, in the right quality, at the right time, at the right cost. Optimized networking of the global chemical sites is therefore an important task for logistics in order to be able to keep pace with the growing demands on flexibility, transparency and security. Optimized logistics processes ensure strategic competitive advantages.

The main tasks of chemical logistics are designing and optimizing, controlling, executing and monitoring the supply chain with regard to procurement , production and distribution of chemicals.

storage

Safe storage of the chemicals must be made to protect everyone and the environment. Therefore, a large number of different storage facilities are required, including solid storage facilities, gas storage facilities, cold storage facilities, liquid storage facilities, explosives storage facilities, etc. These must be under constant surveillance through, for example, monitoring and audit trails . The chemicals are present as hazardous substances during storage and are differentiated into different classes of hazardous substances, so the safety measures, for example, with regard to the risk of fire, explosion and poisoning, are also adapted. The chemicals are labeled according to GHS (GHS is a worldwide system for the standardization and harmonization of the classification and labeling of chemicals).

Measures to store chemicals

- The warehouse concept and the risk assessment must be drawn up by the employer. He is also obliged to ensure that safety data sheets and protective clothing are available, regulations are observed and responsible employees are trained.

- For storage and the associated activities, additional operating instructions must be available that stipulate the behavior when handling chemicals and storage.

- An emergency plan describing what to do in the event of fire, accident or leakage must also be drawn up for each warehouse. This should be hung in a clearly visible place in the warehouse.

- Storage facilities must be checked for their function, reliability and effectiveness for the first time when they are set up and later at regular intervals.

Basically, a warehouse for chemicals must have the following. The warehouse must stand on thick, solid ground and be protected from flooding. Storage rooms must have chemical-resistant building materials. Access and escape routes must be fully accessible at all times. The storage room may only be accessible to authorized persons. The storage room must meet fire protection requirements, be made of non-flammable materials and have sufficient fire extinguishing equipment. The storage room must be adequately lit and the lamps must not heat the stored products. Suitable collection facilities must be provided in the event that chemicals are released.

Risk assessment

A risk assessment must be carried out (according to Sections 5 and 6 of the ArbSchG ) in order to determine whether the storage of chemicals or hazardous substances poses a risk to employees or other people. In what quantities can chemicals be stored in certain locations? What dangerous properties do they have? The product labels and safety data sheets provide important information on the risk assessment of individual chemicals. Not only the individual products, but also the organizational work processes such as the delivery of new products or the cleaning of empty collection and safety containers are important for correct storage. The storage of hazardous substances is regulated in the Ordinance on Hazardous Substances of November 15, 2016.

Comprehensive storage concept

In the storage concept, all safety-relevant aspects of a warehouse are recorded, from the premises and the organization of the warehouse processes to the documentation of the type and quantity of chemical substances. The storage concept therefore not only offers a good overview of stored materials, but can also prevent hazards and provide the necessary information in an emergency. All companies that store chemical substances should therefore generally have such a storage concept. Since the chemicals are hazardous substances, suitable and adequately labeled packaging must be selected. These must be closed and, if possible, stored in the original packaging. The leakage of the substances must be excluded. Different classes of hazardous substances may only be stored separately. Chemicals may also not be freely stacked; depending on the safety description, a stacking ban may also be stipulated.

Storage plan

A storage plan that contains information on the specific location and the quantities of the various chemicals provides the necessary overview of stored products . This plan should contain information on the names of the chemicals, the hazardous properties, the total permitted storage quantity and the various storage sections.

Storage location

In order to store chemicals correctly, it is forbidden to store them in places where there may be an increased risk to people. These include stairs, corridors, break rooms and sanitary rooms as well as living rooms. A separate warehouse is particularly important for storing large quantities of chemical-technical products. Certain conditions apply to storage in workrooms. Under certain circumstances, chemicals can be stored in safety cabinets, so-called hazardous material cabinets.

Joint storage of chemical substances

Whenever the joint storage of different chemicals would increase the risk, the products must not be stored together. In particular, chemicals should not be stored together if

- they need different extinguishing agents

- they need different temperatures

- they can react with each other when released or cause a fire. However, not all chemicals may be stored together with similar substances. To make matters worse, the labeling does not always allow conclusions to be drawn about possible reactions between different chemicals. Separate storage is required in the following cases for chemical substances with different hazard characteristics:

- Explosive substances must be stored separately from other hazardous substances

- Spontaneously flammable substances must be stored separately from hazardous substances that are explosive, burn or can cause a fire

- Oxidising substances must be stored separately from combustible substances

In general, flammable liquids must not be stored together with hazardous substances. They must be stored in separate safety cabinets and in their own shelf trays.

The joint storage table of the technical rules for hazardous substances provides an overview of storage options and is a decision-making aid for the joint storage of hazardous substances. It indicates whether and in what form joint storage is permitted or prohibited. Information on the storage of chemicals can always be found in the safety data sheets for the individual products.

transport

Mode of Transport

The chemicals to be transported can be dangerous goods . According to the Transport of Hazardous Goods Act , dangerous goods are "substances and objects which, due to their nature, their properties or their condition in connection with the transport, pose a threat to public safety or order, in particular to the general public, to important commons, to life and health of people as well as for animals and things “.

The regulations for marking and securing dangerous goods differ depending on the type of transport. There are also regulations for the international transport of dangerous goods, such as ADR for road transport, ADN for inland water transport, RID for rail transport and IATA for air freight. These supranational regulations are incorporated into national law in the individual countries through national legislation. In 2007, 395 million tons of chemicals were transported, 40% of which were classified as dangerous goods (70% of which were petroleum products). Chemicals are divided into 13 dangerous goods classes. Transport also includes acceptance and acceptance of the goods, which is why transport begins with packaging and ends when the goods are unpacked again.

During the transport of dangerous goods, these can be monitored more closely than non-dangerous goods. Telematics systems such as B. Round trip monitoring , geofencing and temperature monitoring . The resulting transparency of the supply chain through information transfer in real time also helps to optimize orders.

Suppliers

The supply chains of the German chemical industry are increasingly networked internationally.

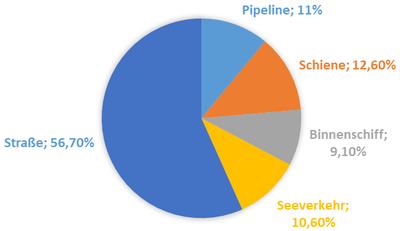

In 2014, around 245.1 million tons of chemical products were transported (by pipeline ) in Germany . This makes the chemical industry in Germany one of the most transport-intensive sectors. It is responsible for 6.2 percent of the total freight traffic. Nationwide, it is the second largest customer of transport services, because a large part of chemical production goes to industrial processing .

Outsourcing

Outsourcing generally describes a form of organization in which a company transfers complete work areas or parts of them to another company in order to save costs.

Chemical companies choose to outsource to:

- Reduce costs by 10 to 15% on average

- to focus on the core business

- Optimize processes

- To have services processed securely in accordance with the guidelines

Trends

Outsourcing and globalization of value chains are considered general trends . China is becoming more and more important as a trading partner for Germany, as the state cannot meet its own demand for chemical products despite increasing production. In March 2017, China had a deficit of 60 billion euros in this regard. The trend towards security of supply for chemical production to chemical sales locations is to be guaranteed across Europe by so-called chemical hubs. These hubs should be understood as a conglomerate of chemical sites or as a warehouse and transshipment point with excellent logistical prerequisites. At the moment (2018) they have to do without due to incompatible rail and road networks, legal or non-existent standards in Europe.

education

In terms of sales, the chemical industry is the third largest branch of industry in Germany. Its largest companies in Germany include BASF and Bayer AG . Despite the size of the industry, there will be no special training as a logistics specialist in chemistry until 2018. Regular training as a warehouse logistics specialist is supplemented with appropriate training in chemical companies. You can also choose between different logistics courses, but you can only acquire the necessary chemical knowledge through further training. The University of Kaiserslautern has had a chemical and pharmaceutical logistics course since 2015, which is unique in Germany .

literature

- Carsten Suntrop (Ed.): Chemical logistics: market, business models, processes . Wiley-VCH, Weinheim 2011, ISBN 978-3-527-32531-3 .

Web links

Individual evidence

- ^ A b c Marc-André Hessen, Matthias Klump: Future trends in chemical logistics . Ed .: Matthias Klump (= ild series of publications on logistics research . Volume 20 ). 2011, ISSN 1866-0304 ( econstor.eu [PDF]).

- ↑ a b chemical logistics. In: baustoffwissen.de. RM Handelsmedien GmbH & Co. KG, accessed on May 30, 2018 .

- ↑ a b c d e f g h Rolf Dietmar Grap, Birte Milnickel: Chemical logistics in the context of general logistical requirements . In: Carsten Suntrop (Ed.): Chemielogistik . Wiley-VCH Verlag & Co. KGaA, Weinheim 2011, ISBN 978-3-527-63423-1 , pp. 1–22 , doi : 10.1002 / 9783527634231.ch1 .

- ↑ Chemical trade: complexity determines logistics. In: chemanager-online.com. Wiley-VCH, April 26, 2011, accessed May 6, 2018 .

- ↑ Explained: What does "logistics" mean? In: baustoffwissen.de. Retrieved May 4, 2018 .

- ↑ BVL: Chemical logistics trends show high development potential. In: chemanager-online.com. Wiley-VCH, accessed April 25, 2018 .

- ↑ Chemical logistics: a topic for the board of directors! In: chemanager-online.com. Wiley-VCH, accessed April 25, 2018 .

- ↑ a b c d e Guide: Store chemicals correctly in the company. In: contorion.de. June 7, 2016, accessed May 4, 2018 .

- ↑ Storage of hazardous substances. (PDF; 567 kB) University of Duisburg, accessed on May 12, 2018 .

- ↑ Store hazardous substances safely. VBG , accessed on May 4, 2018 .

- ↑ Law on the transport of dangerous goods (Hazardous Goods Transport Act, GGBefG), § 2 (1)

- ↑ CMR: the consignment note. In: logistikknowhow.com. Retrieved May 6, 2018 .

- ↑ Chemical logistics: A gateway to BASF, Bayer and Lanxess. In: logistik-heute.de. Huss-Verlag, June 13, 2013, accessed on May 29, 2018 .

- ↑ Much more than just from A to B developments and current trends in pharmaceutical and chemical logistics. In: ACHEMA.de. Retrieved June 11, 2018 .

- ↑ BVL: Chemical logistics trends show high development potential. In: chemanager-online.com. Wiley-VCH, accessed May 15, 2018 .

- ↑ Outsourcing can give wings to chemical logistics. In: chemanager-online.com. Retrieved June 1, 2018 .

- ↑ Luisa Walendy: Chemical logistics - an upswing industry needs efficient processes. In: inform-software.de. September 12, 2017. Retrieved May 4, 2018 .

- ↑ Chemical and pharmaceutical logistics. University of Applied Sciences Kaiserslautern , accessed on May 30, 2018 .