Bucket ladder excavator

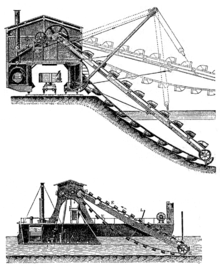

Bucket chain excavators are large continuously conveying excavators that are mainly used in water and open-cast mining . The basic principle of a bucket chain excavator is to dig up the conveyed material with buckets that are attached to an endless chain. The bucket chain runs over a drive and a deflection turas and consists of joint links called hooks, the buckets being welded directly to individual bucket hooks. The chain is driven via the drive turas by means of a powerful electric motor including gearbox or an electric motor with frequency converter without gearbox (so-called direct drive).

Open pit

In surface mining , they are the oldest large mining equipment used. The technical idea for building these devices goes back to the 16th century, when devices based on the principle of circulating bucket chains were first used to build canals. A bucket chain excavator was used for the first time in opencast lignite mining in the Borna mining district in 1885 . This had an unguided bucket chain and a rigid superstructure and was driven by an 81 kW (110 hp) steam engine.

construction

A bucket ladder as the leading steel construction for the bucket chain in the area of the embankment consists of several parts (bucket ladder, if necessary high or deep excavator leveling piece), which are suspended from a pulley head and can be raised and lowered using ropes .

Basically, bucket chain excavators distinguish between:

- Portal excavators on rail trolleys, which are used in the overburden and in front cutting. Portal excavators transfer the conveyed mass to conveying devices arranged between the rail bogies.

- Side shocks on crawler tracks , which are preferably used in deep cuts. Side shocks convey via a pivoting loading arm. They work exclusively in block cutting and are used in particular in the production of ramps and incisions as well as in the extraction of useful minerals in deep cutting.

Working method

Bucket chain excavators were originally designed for deep cutting, that is, for dismantling under one's own stand base. Modern bucket chain excavators for excavation of overburden in opencast mines can work with almost identical removal heights in deep cut and high cut. That makes this type of excavator unique.

Advantages and disadvantages

The operation of bucket chain excavators has the following advantages:

- comparatively high performance

- When operating in deep cut, material can be conveyed from a higher (stable) working level, which, unlike other devices, does not have to convey lying waste

- In addition, with the bucket chain excavator, part of the lifting work is carried out in the device in the deep cut, which is advantageous for means of transport with low permissible inclinations (e.g. train operation)

- the operation of the bucket chain excavator in parallel section largely corresponds to the operation of the conveyor bridge , which is why these opencast mining devices are preferably combined.

- The bucket of a bucket chain excavator can push material in front of it outside of the bucket, which enables a high degree of bucket utilization (up to approx. 170% of the bucket volume)

Disadvantages of the bucket chain excavator are:

- comparatively high investment costs

- only relatively soft rock can be removed, as only the weight of the bucket ladder ensures the pressure is applied (with harder rocks the buckets slide away over the rock)

- high maintenance costs (especially due to the wear and tear of the bucket chain and turret )

- comparatively low operational flexibility

Combination with other device chains

In the Lausitz area, two or three excavators are used in a permanent network with an overburden conveyor bridge to extract overburden .

Dredging

In dredging, d. H. Bucket chain excavators are also used in the extraction of useful minerals under water or the construction of infrastructure on / in the water. These differ essentially in terms of location (land / sea-based, seaworthy) and the purpose (e.g. mineral extraction, maintenance dredging). If the devices are land-based, they are sometimes called scrapers or scrapers, although scrapers are often constructed differently and, strictly speaking, cannot be equated with bucket chain excavators.

Sea-supported bucket chain excavators are mainly used for the following construction projects:

- Deepening or expansion of existing ship berths or dock pits,

- New construction of ship berths (use in "heavy" or strongly cohesive soil),

- extensive maintenance dredging.

- Another area of application is the expansion or deepening of waterways ( fairway adjustment ).

- In mining, they are usually found in gravel pits or when extracting soap deposits .

In the case of maintenance dredging, the river bed in the affected dredging field is brought back to the target depth (created in the past). The dredged material is loaded into flushing barges , collapsible barges or barges (also barges or push barges ) and then transported , depending on its origin, location, type of soil or intended use . Then the dredged material

- returned to the water in a suitable place and at a suitable time (dumping of the dredged material - in areas affected by the tides, e.g. during a time window with "running water" and only between the beginning of November and the end of March),

- sucked out of the flushing chutes by means of a chute suction device, pumped through pipes, flushed into a storage basin and then processed and built into landfills in layers.

In the case of oil-contaminated dredged material, the barges are towed to a special unloading location. There the dredged material is unloaded with a grab excavator and loaded onto specially sealed trucks . The dredged material is placed in designated landfills or reprocessing plants.

literature

- Reinald Skiba : Taschenbuch Betriebliche Sicherheitstechnik . 3rd edition, Erich-Schmidt-Verlag, Regensburg / Münster 1991, ISBN 3-503-02943-5

- Walter Bischoff , Heinz Bramann, Westfälische Berggewerkschaftskasse Bochum: The small mining dictionary . 7th edition, Verlag Glückauf, Essen 1988, ISBN 3-7739-0501-7

Web links

References and comments

- ↑ maintenance dredging in the English language Wikipedia