RuK softening point

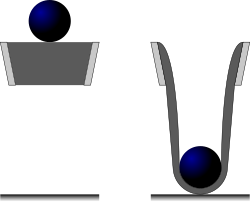

The ring and ball softening point ( EP RuK for short ) is a measured value for the classification of bitumen .

When determining this value, a steel ball is placed on a layer of bitumen in a ring. In the course of the experiment, the material is heated evenly. When the sample has deflected downwards by 25.4 ± 0.2 millimeters, the corresponding temperature is recorded. This experiment is carried out twice.

The steel ball has a diameter of about 9.5 millimeters and a weight of 3.5 grams . The weight may deviate upwards and downwards by 0.05 grams, the diameter by ± 0.05 millimeters. The ring has an outer diameter of 23 and an inner diameter of 19.8 millimeters at the top, an outer diameter of 19 and an inner diameter of 15.9 millimeters at the bottom. Deviations of 0.1 millimeters are permitted from these values.

execution

Usually three samples are prepared and tested at the same time. In accordance with DIN EN 12594, the bitumen is heated to 100 ° C above the expected softening point; for filling polymer-modified bitumen at 180 to 200 ° C, unless otherwise specified. The rings themselves are heated up to 100 ° C above the expected softening point. They are then placed on a plate prepared with a mold release agent so that the larger diameter faces up. Then you fill the interior of the rings completely and slightly convex on the surface with the liquefied bitumen to be tested. After 30 minutes of cooling, the bitumen protruding over the edge is cut off so that the surface becomes smooth and even. It must be ensured that the sample is cut off after 30 minutes at the earliest . Bitumen, which is already soft at room temperature, is allowed to cool at least at a temperature of about 10 ° C below the expected softening point.

The rings are then placed in a holder. The ball is first placed in a holding position located on it above or next to the sample. A plate is attached under the ring at a distance of 25.4 ± 0.2 millimeters. Then everything is put together in a beaker and filled with liquid. The liquid must be up to 50 ± 3 millimeters above the rings. Then a thermometer is inserted so that it is level with the rings but not touching them. The type of liquid and the thermometer depends on the expected softening point. Freshly boiled, cooled and distilled or deionized water is to be used between 28 and 80 ° C and glycerol with a density of 1,250 ± 10 kg / m³ is to be used between 80 and 150 ° C.

At the beginning, the apparatus is kept at the initial temperature for 15 minutes. Then the ball is rolled onto the sample. The stirrer used rotates at about 100 revolutions per minute . Then the liquid is heated so that the temperature rises by 5 ° C within one minute. The first three minutes are used to set the temperature rise. Thereafter, the temperature rise may only be between 4.4 and 5.6 ° C per minute. If this is not observed, the sample must be discarded. When the deflected sample reaches the plate, the temperature is read. This experiment is carried out twice. If the temperatures are more than 1 ° C apart, the experiment is invalid and must be repeated.

See also

Norms and standards

- DIN EN 1427 Bitumen and bituminous binders - Determination of the softening point - Ring and ball method

- DIN EN 12 591 - Requirements for road construction bitumen

Individual evidence

- ^ D. Richter, M. Heindel: Straßen- und Tiefbau, BG Teubner Verlag, 2008, ISBN 3-8351-0057-2 , page 364