thermometer

A thermometer ( ancient Greek θερμός thermós , German 'warm' and ancient Greek μέτρον métron , German ' measure , measure' ) is a measuring device for determining the temperature .

Many thermometers are based on the temperature dependence of the expansion of liquids, gases or solids, the expansion coefficient of which is known. To do this, the measuring point of the thermometer must assume the temperature of the object being measured. In addition to this mechanical measuring effect , various temperature-dependent electrical influences are used, e.g. B. the effect of temperature on the electrical resistance .

Pyrometers, on the other hand, measure without touching the object to be measured using the temperature radiation emitted which is characteristic of the temperature .

Each thermometer consists of a temperature sensor (in which the measuring effect occurs) and a display (e.g. using a scale ) or a connection point for an electrical signal .

Thermometers are adjusted using fixed temperature points, such as the triple or melting points of certain materials, or using a calibrated reference thermometer .

history

The development of the thermometer cannot be attributed to the invention of a single person. Rather, numerous scientific findings were necessary that led to our current concept of temperature and enabled the introduction of a temperature scale and its technical implementation.

The sensations “hot” and “cold” are directly linked to the sense of touch , which, however, hardly allows a reliable determination of different degrees of warmth. Greek philosophy dealt with the pair of opposites hot and cold in its considerations, but made no attempt at a numerical description. The Greek doctor Galen introduced eight “degrees of heat and cold” in the second century: four degrees each above and below a neutral center point, which should correspond to a mixture of equal amounts of ice water and boiling water.

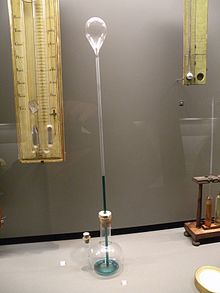

Already in antiquity the thermal expansion of air caused by temperature changes was used to set various mechanisms in motion, for example by Philon of Byzantium or Heron of Alexandria . But it wasn't until the early 17th century that this principle was used in a forerunner of the thermometer, the thermoscope , to determine temperatures. It was a glass ball with a long, thin glass tube attached, the lower opening of which was immersed in water. The changes in the volume of the trapped air caused by changes in temperature caused the water column in the pipe to rise or fall. At least initially, the thermoscope did not have a scale; the length of the water column was measured with a pair of compasses.

From 1612 Giovanni Francesco Sagredo described in letters to Galileo Galilei how he made such instruments, the invention of which he attributed to Galileo, in various forms. He used it to observe the temperature of the cold winter air, kept records of a summer heat wave and compared the temperatures of lakes of different sizes. The doctor Santorio Santorio from Padua, who was in contact with Galileo, used his scientific knowledge medically and used both thermoscopes to measure temperature and pendulums to measure pulse. Santorio used snow and a candle flame as two reference points to calibrate the thermoscope.

All thermoscopes used up to then did not use the thermal expansion of the liquid, but that of the air. Basically they resembled a barometer and were therefore particularly dependent on the air pressure, as was known from Evangelista Torricelli at the latest in 1643/44 . Ferdinando II. De 'Medici , Grand Duke of Toscana, had the first thermometer manufactured in 1654, which exploited the expansion of alcohol in a closed glass tube.

From around 1714 Daniel Gabriel Fahrenheit in Amsterdam replaced alcohol with mercury and invented the mercury thermometer . 1724 beat Daniel Gabriel Fahrenheit named after him temperature scale before that the coldest point of a freezing mixture defined as 0 ° F, the melting point of water as 32 ° F and the human body temperature of 96 ° F. Anders Celsius determined his scale in 1742 based on the melting and boiling points of water, but the other way around than the scale that is named after him today.

In 1859 Gustav Robert Kirchhoff formulated the radiation law named after him , which laid the foundation for thermometers based on temperature radiation .

Types of thermometers

Touch thermometer

Contact thermometers require thermal contact with the measurement object. Measurement deviations occur here mainly due to insufficient thermal contact with the measurement object or if the thermometer dissipates too much heat.

- Expansion thermometer ( liquid thermometer (also earlier common mercury clinical thermometers ), bimetal thermometers )

- Vapor pressure thermometer (relationship between the vapor pressure of a liquid and the absolute temperature - Clausius-Clapeyron equation )

- Thermocouples (NiCr / Ni, PtRh / Pt, Fe / CuNi etc.) in connection with indicating measuring devices or measuring amplifiers

- Resistance thermometer with platinum ( Pt100 ) and thermistors / NTC thermistors in connection with indicating measuring devices or electronic circuits

- Temperature sensors , in particular integrated circuits with temperature output

- Foil thermometers , temperature measuring strips, adhesive pads with irreversible color change or liquid crystal thermometers (e.g. wine bottle thermometers) are based on the thermochromic properties of liquid crystals.

- Gas thermometer (evaluation of a pressure measurement)

In a broader sense, thermometers also include maximum value indicators or Segers cones .

Heating thermostatic valves and thermostatic mixer taps with expansion elements , however, are not thermometers, but regulators .

Contactless measuring thermometers

Non-contact thermometers ( pyrometers ) use the property that objects emit electromagnetic thermal radiation due to their own temperature . At below 500 ° C (until the onset of red heat ) it is in the range of infrared radiation . Infrared sensors are therefore required for non-contact temperature measurement in this area . In the past, pyrometers were divided into the following categories:

- Low temperature pyrometer (approx. −20… 200 ° C), measuring wavelength around 5 µm… 15 µm

- High temperature pyrometer (400… 3000 ° C), measuring wavelengths 1 µm… 1.5 µm

A further subdivision can be made based on the bandwidth of the evaluated radiation:

- Total radiation pyrometers measure a large part of the emitted wavelengths (e.g. using a bolometer )

- Band radiation and narrow band pyrometers measure a narrow range of wavelengths and usually have a photo receiver as a radiation sensor

- Ratio pyrometers measure at two wavelengths and can reduce the influence of the emissivity on the measurement error without knowing it

Later the radiation thermometers were also divided according to the measurement wavelengths:

- Long-wave measuring pyrometers (−50 ... 1600 ° C), measuring wavelength: 3.43 µm ... 14 µm

- Short-wave measuring pyrometers (50 ... 3000 ° C), measuring wavelength: 0.8 µm ... 2.7 µm

An example of a long-wave measuring thermometer is the infrared clinical thermometer .

Also thermography cameras are combined with an image-performing software suitable as a thermometer. It provides two-dimensional temperature profiles ( thermal images ) that are used in mechanical engineering, automation , R&D , medicine , security / monitoring technology and construction . The often used false color representation assigns a temperature to each color. A colored wedge with a temperature scale is often displayed in the image.

Others

A thermometer based on gravity and temperature-dependent density of a liquid, the Galileo thermometer , was not invented by Galileo Galilei , but only named after him.

Raman thermometers, based on Raman spectroscopy (see also fiber optic temperature measurement ), use a frequency-stable measuring beam and evaluate its backscatter. You can measure spatially resolved along one dimension.

calibration

For the calibration of thermometers there is the international standard ITS-90 . Based on this standard, the Physikalisch-Technische Bundesanstalt (or the German Calibration Service or in Great Britain the UKAS - United Kingdom Accreditation Service ) calibrates platinum thermometers, which are then used as a reference for manufacturers. The following temperature points are used:

| Defining fixed points | ||

|---|---|---|

| State of equilibrium | temperature | |

| Absolute zero | −273.15 ° C | 0 K (exact) |

| Triple point of hydrogen in the equilibrium state | −259.3467 ° C | 13.8033K |

| Equilibrium hydrogen at a vapor pressure of 32.9 kPa | −256.1 ° C | ≈ 17.0 K |

| Equilibrium hydrogen at a vapor pressure of 102.2 kPa | −252.9 ° C | ≈ 20.3 K |

| Triple point of neon | −248.5939 ° C | 24.5561K |

| Triple point of oxygen | −218.7916 ° C | 54.3584 K |

| Triple point of argon | −189.3442 ° C | 83.8058 K |

| Triple point of mercury | −38.8344 ° C | 234.3156K |

| Triple point of water | +0.01 ° C | 273.16 K |

| Melting point of gallium | +29.7646 ° C | 302.9164K |

| Solidification point of the indium | 156.5985 ° C | 429.7485K |

| Freezing point of tin | 231.928 ° C | 505,078K |

| Solidification point of the zinc | 419.527 ° C | 692.677K |

| Solidification point of the aluminum | 660.323 ° C | 933,473K |

| Freezing point of silver | 961.78 ° C | 1234.93K |

| Freezing point of gold | 1064.18 ° C | 1,337.33K |

| Solidification point of the copper | 1084.62 ° C | 1,357.77 K |

The calibration of the reference thermometer takes place in so-called fixed point cells. These are dewar vessels in which, on the one hand, the fixed temperature point is achieved, for example by heating indium to its melting point. On the other hand, a tube enables the sensor of the reference thermometer to be introduced.

Measurement error with contact thermometers

Static deviation

A measurement deviation of a thermometer is caused

- on the one hand due to the limited readability: the liquid level in a conventional liquid thermometer can hardly be read off more precisely than a millimeter, nor is it possible to read off the temperature with a digital thermometer more precisely than with a digit increment . The same applies to electrical measuring devices.

- on the other hand, due to the limited adjustability: the manufacturer can only guarantee conformity with the correct value within certain limit deviations . For liquid thermometers they should be given in an associated data sheet. There are standardized specifications in various accuracy classes for industrially used thermocouples and platinum resistance thermometers .

Another source of error occurs with liquid glass thermometers : not only the thermometric liquid, but also the capillary expands with increasing temperature. Both must have assumed the same temperature as the measuring point. If the thermometer is operated under different conditions than during its adjustment, a thread correction is required. Furthermore, the frequently occurring parallax error should be avoided with liquid-glass thermometers . It is also important to ensure that the liquid may have dispersed in the capillary during storage and first has to be tied back into a thread by tapping or spinning.

Dynamic deviation

With all temperature changes , the measured value follows the actual temperature with a delay because heat has to be transported to adjust the temperature. For the thermal contact of the thermometer with the object to be measured, consider

- whether it is to be used for a laboratory test or whether it has to be protected from corrosive, aggressive and abrasive media in a production process

- whether a gas or liquid temperature is to be measured

- The speed at which the material to be measured flows around the thermometer

| ⌀ in mm |

Air at 1.0 m / s | Water at 0.4 m / s | |||

| in s | in s | in s | in s | ||

| Liquid glass thermometer (Hg) | 6th | 40-60 | 120-180 | 3 - 5 | 6-10 |

| Steam pressure spring thermometer in protective tube | 22nd | 350-400 | 1200-1400 | 80-90 | 240-300 |

| Thermocouple measuring insert | 6th | 40-60 | 150-180 | 0.3-0.8 | 1.0-1.5 |

| Thermocouple in protection tube form C | 11 | 100-120 | 320-400 | 7-9 | 30-50 |

| Thermocouple in protection tube form D | 24 | 320-400 | 900-1200 | 10-20 | 60-120 |

| Sheathed thermocouple, measuring point isolated | 3 | 20-25 | 70-90 | 0.4-0.6 | 1.0-1.2 |

| Sheathed thermocouple, measuring point isolated | 1.5 | 8-12 | 28-40 | 0.11-0.18 | 0.35-0.5 |

| Resistance thermometer | Transition times 10% to 25% longer than with similarly built thermocouples |

||||

- its diameter (⌀).

Characteristic for the time behavior are transition times in which the measured value follows a sudden change in temperature, namely 50% and 90%. The adjacent table gives excerpts from empirical values from VDI / VDE 3511, sheet 2 (contact thermometer) .

See also

literature

- VDI / VDE guideline 3511 Technical temperature measurements , sheets 1 to 5

Web links

Individual evidence

- ^ Gerhard Stöhr: Thermometry - History. Friends of old weather instruments, 2002, accessed September 4, 2012 . (archived)

- ^ A b WE Knowles Middleton: A History of the Thermometer and Its Use in Meteorology. Johns Hopkins, Baltimore 1966, ISBN 0-8018-7153-0 , p. 3

- ↑ a b Th.D. McGee: Principles and Methods of Temperature Measurement. Wiley, New York 1988, ISBN 0-471-62767-4 , pp. 2f and Fig. 1.1, Google Books Preview

- ^ A b WE Knowles Middleton: A History of the Thermometer and Its Use in Meteorology. Johns Hopkins, Baltimore 1966, ISBN 0-8018-7153-0 , p. 6

- ^ WE Knowles Middleton: A History of the Thermometer and Its Use in Meteorology. Johns Hopkins, Baltimore 1966, ISBN 0-8018-7153-0 , p. 10

- ^ WE Knowles Middleton: A History of the Thermometer and Its Use in Meteorology. Johns Hopkins, Baltimore 1966, ISBN 0-8018-7153-0 , p. 7

- ^ Fritz Burckhardt : The invention of the thermometer. Basel 1867, after G. Stöhr ( Memento from September 4, 2012 in the Internet Archive ).

- ^ Herbert Windisch: Thermodynamics: A textbook for engineers. 5th edition. de Gruyter Oldenbourg, 2014, p. 15.

- ↑ Klaus Irrgang (Ed.): Temperaturmesspraxis with resistance thermometers and thermocouples. Vulkan, 2004, p. 3.

- ↑ Frank Bernhard (Ed.): Manual of technical temperature measurement. 2nd Edition. Springer Vieweg, 2014, p. 39, 524ff.

- ↑ Peter Stephan, Karlheinz Schaber, Karl Stephan , Franz Mayinger: Thermodynamics: Fundamentals and technical applications, Volume 1: One- material systems. 19th edition. Springer Vieweg, 2013, p. 17.