Liquid color

The term Liquid Color ( English Liquid Color ) or liquid color concentrate is meant a system consisting of a liquid binder (carrier), colorants or pigment preparations , as well as other additives such as process additives, stabilizers or the like exists. The liquid colors are added to the plastic (raw polymer) for coloring or to change the properties.

There are generally three groups of liquid colors.

- Liquid colors that are used to color plastic products.

- Liquid additive concentrates that ensure certain properties of the end products, such as UV stabilization, flame protection , antistatic or antiblocking.

- Combination liquid colors that contain both colorants and additives.

History and market relevance

So-called liquid colors have been used for coloring plastics since the late 1960s / early 1970s. However, liquid colors are still not used across the board and have a market share of just 7% in Europe compared to masterbatch coloring with 93%. This is different in the USA, where the market share of liquid colors is around 40%. This is mainly due to the inadequate dosing technology in the early days and the associated contamination in the production area. As a result, the liquid color received a bad reputation and is still not very popular with processors, although the dosing systems have been adapted to the requirements of the users, especially in the last decade, and clean and easy handling is possible.

Areas of application

It is possible to supply liquid colors to a variety of thermoplastic and thermosetting processing methods, such as B .:

- Film extrusion / deep-drawing films

- Foam extrusion

- Blown film

- Profile extrusion

- Injection molding

- Injection blow molding

- Casting compounds

- Plastisol hot dip process

The products obtained from the processing methods are z. B. Application in the following areas:

- Packaging industry

- Medical technology

- Automotive industry

- Furniture industry

- Electronics industry

- Toy industry

Manufacturing

Depending on the plastic, the choice of the liquid system is decisive due to the processing temperatures, compatibility and subsequent application. In order to prevent migration of the carrier liquid as far as possible, well-tolerated liquid carriers are used that interact with the polymer.

The typical components are:

- Fatty acid esters or fatty acid ester ethoxylates

- Plasticizers

- Paraffin, mineral and natural oils

- Alkyd oils

- Polyisobutylene

- polyhydric alcohols or alcohol ethoxylates

- Additives such as wetting agents and viscosity regulators

- lubricant

- Antistatic agents

Various mixtures of the components are also used.

The pigment preparations are produced in batches. For this purpose, the formulation components are distributed in a binding agent previously selected for the respective application and then dispersed. The most optimal possible break-up of agglomerates is crucial in order to ensure that the color concentrates and / or the functional process additives are highly effective. Dissolvers , bead mills and roller mills are mostly used here. For transparent, thin film applications, particularly well-digested pigments are required. In practice, particle sizes <5 μm have proven useful for film applications.

Dosing technology

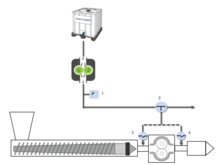

The liquid colors can be dosed in different ways. The simplest option is what is known as drumming. Here the polymer granulate is wetted with the liquid color, homogenized in a mixing device and usually processed further. In industrial applications can usually gravimetric or volumetric metering units such as peristaltic pumps , progressive cavity pumps , piston pumps or gear pumps application. Dosing can be done via the funnel or directly into the melt.

Advantages and disadvantages

advantages

Due to the batchwise production, the pigments can be digested in the liquid carrier medium until they are optimally dispersed. The particles are therefore very finely distributed, which has a positive effect on color strength and light scattering.

Every batch can be checked in terms of color, viscosity and grain size distribution and corrected as a whole if necessary.

If the liquid color is added to the main funnel together with the crude polymer, the result is a statistically better distribution of the liquid color compared to masterbatch even before melting. In this way, homogeneous, streak-free coloring can be achieved without additional mixing units with highly concentrated liquid color from a dosage of 0.5%.

Due to the wetting with a liquid carrier, the pigments adhere less strongly to the metal components of the processing machines, which in some cases results in significantly reduced color change times. The number of cleaning cycles can be reduced, particularly when using hot runner systems. In addition, it is possible to inject the liquid color downstream into the plastic melt using the appropriate dosing technology. This means that when changing colors, only a part of the production line needs to be rinsed, which means considerable material and time savings.

The liquid colors are produced at room temperature. A maximum of 40 ° C is reached by shearing. Thus, heat-sensitive pigments such. B. fluorescent or daylight pigments not thermally damaged. Defects such as black specks and streaks are reduced and rejects are minimized.

Liquid colors do not have to be pre-dried, which reduces energy costs and handling effort and also further reduces the thermal load.

The coloring of bio-based plastics with liquid colors leads to an increase in the characteristic value in the notched impact test .

disadvantage

The disadvantages are the high cleaning effort without the use of suitable dosing equipment. When dosing in the feed area, very high coloring concentrations are not possible, as from a certain amount of color onwards, the plasticizing screw can be over-smeared due to the system. This means that the liquid film on the plasticizing screw is too high, which hinders the uniform transport of the polymer granulate. The maximum ink dosage depends heavily on the polymer used (grain size, surface properties and surface energy), the machine configuration and the pigment load in the liquid color. This can lead to problems with very thin-walled parts that have to be colored as opaque as possible, or coloring with liquid paint can even be completely ruled out.

In the case of inadequately stabilized liquid colors, the colorants can settle out. This can lead to uncontrolled flocculation, ie pigment particles are in direct contact with one another and they can only be separated from one another by high shear forces. When using suitable additives, pigment particles are linked to form a network via additive molecules. There is therefore no direct pigment-pigment contact. Such flocculates are by low shear forces, such. B. a manual stirring to destroy.

Individual evidence

- ↑ a b c d Hendrik Hesse: Analysis of the possible uses of liquid color concentrates in film applications . Aachen University of Applied Sciences, Jülich 2016.

- ^ A b Richard L. Abrams: Liquid Color Concentrates . In: Coloring of Plastics . John Wiley & Sons, Inc., 2003, ISBN 0-471-72158-1 , pp. 287-300 , doi : 10.1002 / 0471721581.ch20 ( wiley.com [accessed January 12, 2018]).

- ↑ S. Klahn: Coloring without the laser noticing . Plastverarbeiter, June 2009, p. 18-20 .

- ↑ a b c Fachagentur Nachwachsende Rohstoffe eV (Ed.): Processing of bioplastics - a guide - . March 2016 (www.biokunststoffe-verarbeiten.de).

- ↑ Liquid colors and additives - Products - Dosing technology - ROWASOL. Retrieved January 12, 2018 .

- ↑ U. Wilkens: Optical effect of liquid color. ROWASOL GmbH, 2015, accessed on January 1, 2018 .

- ↑ Kohlgrüber, Klemens, Bierdel, Michael: The co-rotating twin screw extruder: Basics, technology, applications . Hanser, Munich 2007, ISBN 978-3-446-41252-1 .

- ↑ Luminescent pigments from Rowasol. Retrieved January 12, 2018 .

- ↑ PresseBox (c) 2002-2018: For gaudy colors: fluorescent pigments from ROWASOL. Retrieved January 12, 2018 .

- ^ Albrecht Müller: Coloring plastics . Hanser, Munich 2002, ISBN 3-446-21990-0 .

- ↑ ALTANA Chemie GmbH: Wetting and dispersing additives. byk.de, accessed on January 12, 2018 .