Semi-pulp

Semi-pulp is a fiber material for paper production that is made from wood and consists primarily of cellulose and parts of lignin . It represents an intermediate stage between cellulose and wood pulp . Semi- cellulose is mainly used for the production of corrugated paper for corrugated board.

background

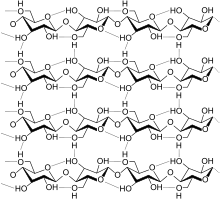

High-quality paper is usually made from cellulose , which consists primarily of cellulose . Cellulose is mainly obtained from wood ( lignocellulose ) using chemical processes (mainly sulphate and sulphite processes ) . Around 50% of the substance is lost because the lignin goes into solution ( black liquor ).

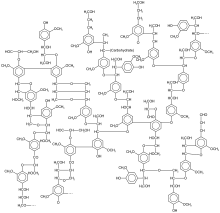

In contrast, less high-quality and durable paper (e.g. newsprint and magazine paper ) is made from wood pulp . In the extraction from wood, the lignin is not removed, so that the yield can be increased to over 90% of the wood mass used. The desired properties of certain types of paper can also be improved by the lignin content. The yellowing caused by the lignin over time can be problematic.

Semi-pulp is an intermediate variant between pulp and wood pulp. The process step for removing the lignin is interrupted at the desired point in time, on the one hand to increase the yield per wood mass or to use the lignin to influence certain properties of the paper made from it. On the other hand, negative effects caused by the lignin content are not completely but at least partially avoided.

Individual evidence

- ↑ Wood fiber product semi - cellulose wellpappe-wissen.de