Lignocellulose

The lignocellulosic (from latin lignum = "timber" or "tree") constitutes the cell wall of woody plants and serves as their structural framework. Hemicelluloses and especially cellulose initially form a framework into which in the process of lignification ( lignification ) subsequently the lignin is stored.

Molecular structure

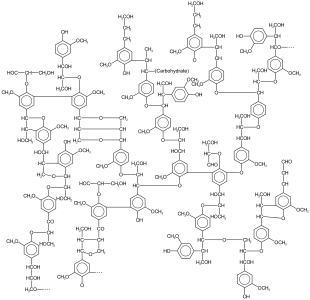

Cellulose is an elongated polymer from numerous β-1,4-glycosidically linked glucose - monomers . A large number of these polymers are aggregated to form fibers with partially crystalline areas. These fibers are arranged along the xylem and give the plant high tensile and flexural strength. Hemicellulose makes up a smaller proportion and is less structured. The reason is that this polymer, consisting of various sugars , also has branching links that do not allow a fiber-like arrangement. Lignin consists of different types of phenylpropanes , which are embedded in the cellulose-hemicellulose framework and linked to form the polymer lignin. The two substances are closely connected and form lignocellulose.

function

A comparison with reinforced concrete is often used to describe the function of lignocellulose . While cellulose, comparable to steel reinforcement , provides tensile and flexural strength, the matrix made of lignin, as an analogue to concrete , is responsible for compressive strength. For example, if a tree is heavily loaded in a storm, the cellulose fibers on the windward side ensure tensile strength. On the leeward side, the lignin deposits prevent the non-massive wood structure from collapsing by giving it compressive strength. In addition, due to its dense structure and linkage, lignocellulose is poorly accessible to enzymes and protects the woody plant from pests such as fungi and bacteria .

use

It is used in the form of wood as a building material and fuel. The cellulose content is used for paper production. Lignin is a waste and disruptive substance that should be present in the lignocellulose used in the smallest possible amount. In various pilot projects, attempts are being made to use lignocellulose from grain , straw , reed , wood , paper and cellulose-containing waste as a renewable raw material for various chemical raw materials. In particular, the phenyl-like compounds in lignin are considered a possible raw material for recycling. The use of lignocellulose as a raw material for biofuels is aimed at with the production of lignocellulose -ethanol . Corresponding manufacturing processes are currently under development or industrial testing. As an inexpensive filler, lignocellulose is used in some industrially manufactured ready-to-use dog foods.

literature

- H. Yu et al .: Microbial community succession and lignocellulose degradation during agricultural waste composting. In: Biodegradation 18/2007, pp. 793-802. PMID 17308882 .

- A. Berlin et al .: Optimization of enzyme complexes for lignocellulose hydrolysis. In: Biotechnology and bioengineering 97/2007, pp. 287-296. PMID 17058283 .

- Nultsch, Wilhelm: General botany. 10th edition. Georg Thieme Verlag Stuttgart, New York 1996.

- Energy from biomass , by Martin Kaltschmitt, Hans Hartmann (as a Google book) .

Individual evidence

- ↑ Keyword lignocellulose. In: Herder-Lexikon der Biologie. Spektrum Akademischer Verlag GmbH, Heidelberg 2003, ISBN 3-8274-0354-5 .

- ↑ B. Kamm, M. Kamm: Principles of biorefineries. In: Applied Microbiology and Biotechnology 64/2004, pp. 137-145.

- ↑ A. Uihlein: The lignocellulose biorefinery: A first ecological balance. (PDF; 437 kB) Research Center Karlsruhe.

- ↑ J. Puls, J. Schweinle: Joint project: pilot project lignocellulose biorefinery, sub-project 2: wood digestion and component separation. (PDF; 188 kB) In: BFH-Nachrichten 2/2007.