Hybrid wood

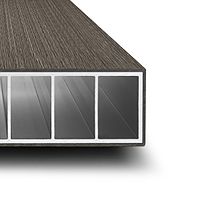

Hybrid wood or WHS ( Wood Hybrid System ) is a multi-layer material, composed of a surface made of the wood composite material WPC , which is firmly fused with a structural core made of aluminum. It was developed in Japan in 2008 and is based on WPC technology invented by Sadao Nishibori in 1972, which was originally created to replace the endangered tropical hardwoods . Hybrid wood is not a fiber-plastic composite (FRP) or glass fiber-reinforced aluminum .

In the construction industry, hybrid wood is mainly used in the construction of facades with a sophisticated and decorative design, as it has the appearance, texture and sometimes even the smell of natural wood. It is easier to install and more powerful than natural wood. Its special properties make it more versatile than wood. Therefore, hybrid wood is already widespread indoors and outdoors, for example for the realization of facade cladding , window shutters, awnings or for outdoor furniture.

Manufacturing

The hybrid wood profiles are manufactured using the extrusion process . A core made of anodized aluminum is sheathed with the wood composite WPC. The optimal adhesion between the two materials is made possible by the application of an adhesive intermediate layer, which is extruded with the wood composite . The WPC sheathing can also only be done on one side of the aluminum profile.

The ratio of wood fibers and polypropylene and the nature of the core vary depending on the properties desired. The production of these profiles has a particularly positive CO 2 balance if all the materials used are made from recycled raw materials.

Actually, one can only speak of hybrid wood if the outer WPC layer is connected to the aluminum core in such a way that the layer cannot peel off, regardless of the climatic or hygrometric conditions it is exposed to. So far, only the process technology of extrusion from a WPC and an adhesive layer can create a connection between two materials that are as different as WPC and aluminum. The adhesive force is so strong that it is possible to bend profiles even over very small radii.

properties

The life expectancy of hybrid wood is significantly higher than that of tropical wood, both for indoor and outdoor applications. Thanks to the aluminum core, a profile made of hybrid wood is significantly lighter than a wooden profile with the same cross-section, at the same time it is more stable (no warping, no cracks, no knotholes) and much stiffer than natural wood. It enables larger spans between two attachment points. The appearance of a building as a whole and the surface of the profiles remain true to the specifications of the designer or architect without maintenance. The material does not rot, is insensitive to weather conditions, solar radiation, fungi and termites .

Due to the physical properties of the core and the aesthetics of the WPC cladding, hybrid wood outperforms

- both the wood composite WPC (due to its mechanical properties, dimensional stability, lightness and ease of installation)

- as well as natural wood (due to its longevity, its color fastness, its extraordinary lengths and cross-sections and the freedom from treatment and maintenance, regardless of the weather conditions or humidity).

installation

Traditional WPC can bend or warp under the influence of weather and UV radiation . Its low mechanical strength makes the use of metal struts necessary, which have to be pushed into the hollow chambers of the profile. However, the significant difference in the expansion coefficient between the two materials WPC and metal often causes problems, even if the installation is correct. Especially in the case of horizontally laid profiles, condensation water remaining between the WPC and the metal can impair the durability.

Hybrid technology enables the production of ready-to-install, quick-to-assemble profiles in all sizes that have the look and feel of wood.

history

In 2008, major technological innovations made it possible to combine two completely different technologies: the extrusion of the WPC component in a well-dosed composition and the adhesive layer applied by extrusion at elevated temperatures. This fusion of two very different materials, the WPC and the aluminum, is only possible thanks to the fine intermediate layer that firmly connects the outer skin and the core.

application

The hybrid wood profiles are ideally suited for both new construction and the renovation of facade elements such as blinds, canopies, balustrades , signs or parapets.

Individual evidence

- ↑ US Patents by Inventor Sadao Nishibori. In: http://patents.justia.com . 1972, accessed January 30, 2017 .

- ↑ Hybrid materials in construction. In: http://www.forum-holzbau.ch . 2012, accessed January 30, 2017 .

- ↑ Documentation. (No longer available online.) Geolam, maker of WPC & WHS, archived from the original on November 13, 2016 ; accessed on January 30, 2017 (English). Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Method for manufacturing wood-like molded product - Patent # 4505869. In: http://www.patentgenius.com . Retrieved January 30, 2017 (English).

- ↑ Wood meal and method of manufacturing the same - Patent # 5665425. (No longer available online.) In: http://www.patentgenius.com . Archived from the original on July 14, 2012 ; accessed on January 30, 2017 (English). Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.