Dome elevator

The dome elevator is an arched elevator in the New Town Hall in Hanover , which leads to the viewing platform on the town hall dome at a height of about 100 meters. It was built by the Flohr company during the construction of the town hall in 1908 and put into operation when the town hall was inaugurated in 1913.

Inclined or bow lift

Due to the parabolic (arched) travel path, the elevator was a novelty, as it is a real rope-hung elevator for the transportation of people without toothed racks. It is often mistakenly called an inclined elevator . An inclined elevator stands or hangs on or on rails or racks and maintains its inclination on a straight course. With the dome elevator in Hanover, on the other hand, the incline changes by around 17 ° during the journey. The Eiffel Tower elevator, which is often used for comparison, is actually "only" an inclined elevator and therefore not comparable.

description

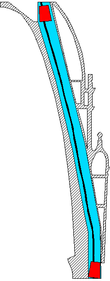

The stroke is approx. 43 m and the offset between entry and exit is approx. 8 m. The elevator and the observation tower above cannot be accessed by handicapped people, so that people with walking disabilities cannot climb the lower access stairs or the spiral stairs in the tower above. The elevator has five stops, of which normally only the end stops are served. The “Kuppelboden” stop is located on the inside of the dome above the entry level. From there you can reach the vault in which the chandelier elevator of the main hall is located. The third stop faces the outside and is the entrance to the tower clock. The stop above is the access to the machine and control room.

First elevator 1908–2007

The car was guided in two steam-bent wooden rails, into which the emergency safety device hit in such a way that 2 × 2 m wooden rails would have been destroyed per catching operation. The drive of the dome elevator was done by two drums with two counterweights. In the winter half of the year, the elevator could not be used because the temperature-dependent, more viscous grease on the rails would not have lowered the elevator and the power supply cable safely under its own weight. The car roof had two windows through which the passengers could see the shaft with its fixtures. Interestingly, the elevator was planned and built together with the construction of the town hall and not, as is the case with many sights, afterwards. In contrast to the surrounding building, this elevator was not a listed building. Over the years, the controls and drives have been replaced several times. Only the basic concept was retained. The number of visitors in the summer months was over 90,000. The old dome elevator had its last ride on November 4, 2007 at 5 p.m. with Lord Mayor Stephan Weil .

New elevator since April 27, 2008

The elevator was replaced in the winter of 2007/08 by a high-tech elevator from Lutz Aufzüge from Reinbek (near Hamburg) based on plans from a Hanoverian planning office for conveyor technology. The driving speed can now optionally be reduced from 0.8 m / s to 0.2 m / s as a sightseeing trip, so that there is more time for taking photos and filming. The two new windows with integrated LCD film in the car floor only become transparent at the push of a button, so that interested parties can also get this impression. The course of the journey and the local situations require special components, which are used, for example, in shunting engine technology and carousel construction. The car has no wired connections to the controller or the drive.

For reasons of space, the drive and control were placed on different levels. The engine room has been expanded at the side for technical installations and improved fire protection. The new elevator is now able to bring passengers safely and independently to the lowest level even if the network fails.

The power transmission to the car should first take place using inductive high-frequency technology. The car should therefore be made of double-shell aluminum so that passengers with electronic pacemakers are maximally protected. As a precaution, however, this technical innovation had to be rescheduled, as it cannot be ruled out that passengers may wear electronic body implants that do not meet European standards.

In particular, this would affect devices that are inductively charged. An uncontrolled unwanted overload would be a possible consequence. As an alternative, electrical conductor lines were used, as they are also used in carousel construction. The possible service life of the carbon brushes is so great that an inexpensive set of carbon brushes is only necessary for replacement after more than four years.

During the planning, there were considerations to manufacture the rails from tubes as in roller coaster construction. These pipes would have been more resilient and easier to manufacture. A compressed air-operated spring-loaded brake from truck construction was initially provided for these pipe guides, but this would first have to be approved for elevator operation. During the planning phase, which lasted several years, a suitable safety gear was developed that also does not require a release rope, but must be installed on T-rails. For these reasons, curved T-rails were used - for the first time in elevator construction. By using these slim rails, the car could be made ten centimeters wider than with pipe guides.

The control commands between the car and the machine room are transmitted via coded radio ( CANopen ). For technical reasons, the two counterweights in the new elevator and all rope-operated speed limiters will also be omitted. This special modification results from the problems of the swinging release ropes, which could otherwise unintentionally trigger the catch. The new safety brake is carried on a gimbal-mounted tender (sledge) and triggered by direct traction on the rails.

The new doors are moved from the vertical to the driving angle. As a result, the car door and the respective shaft door can be automatically connected in a non-positive manner. Manual door opening is therefore no longer necessary. Special heating elements on the doors enable operation even in sub-zero temperatures, snow and ice.

All components are standard components from other trades, which, however, have never been brought together in this combination.

The new elevator is technically set up as a year-round self-drive elevator, but for organizational reasons it is still used as a seasonal elevator with elevator operator operation.

In the picture next to this article you can see the lower entrance of the elevator on an original mother's break from 1902. All heights refer to sea level and not to the relative building height. The manhole was measured stereoscopically in order to be able to use the measurement results to create an exact 3D model on a computer (CAD simulation). Previous measurements are not suitable for bending the rails with the required precision.

Despite high-tech software and state-of-the-art equipment, it was inevitable to correct collisions with walls and manhole installations directly and on site. Even on the first trip with the mayor Weil during the construction phase, the door sill at the level of the engine room was severely deformed when the basket collided with a stone that was still protruding.

The distance between the car and fixed parts of the shaft is less than five millimeters in some places.

The release management is also innovative: should the car no longer be able to be moved by the drive in the shaft, an elevator fitter is mechanically roped down; he relocates the car to a special crane that lifts everything to the next higher level. Contrary to the standard regulations, the emergency call from the car is made by radio transmission. This insecure transmission path is compensated for by several independent devices and radio paths.

In the car there is a photo montage with LED light displays that show the elevator position in the town hall tower. The photo was edited by touching up the front roof that hides the entrance. The current car height above the access stop is displayed above the upper window.