Milking parlor

A milking parlor is a device in which milking clusters are installed and in which the animals are milked.

Common features of all designs

More cows can be milked in a shorter time in a milking parlor than in a tied stall . In addition to cows , an increasing number of goats are being milked in milking parlors. Milking parlors are characterized by the fact that milking staff must be available and that the animals are around one meter higher than the milking staff. The walls of milking parlors are usually tiled . Metal gates control cow traffic and ensure that the cows are positioned according to requirements.

variants

Milking parlors can be divided according to the position of the animals in the milking parlor:

- Tandem : The animal stands parallel to the milking pit .

- Parallel (also: side-by-side ): The animals stand next to each other and their heads away from the milking pit.

- Herringbones : The animals stand at an angle to the milking pit and their heads away from the milking pit.

A pasture milking parlor is independent of the construction is a mobile milking parlor, which can be operated without building terminals.

The number of milking stalls varies and depends on the size of the herd and the desired milking time.

disadvantage

There must be bars to separate the cows that have been milked from those who have yet to go into the milking parlor. Partitions in the stable are often used for this. The disadvantage here is that cows still remain in the cubicles and have to be fetched by a second person. During the milking hours there is limited availability of air, water and space. There should be waiting times of a maximum of one hour per milking time, in practice they are sometimes longer. Technology for recording the milk quantity and milk quality measurement must be purchased for each milking stall. Milking parlors with 10 places are mostly used on farms with 100 cows. Thus, the investment amount for such technology is more uneconomical than it would be with two corresponding milking robot positions . Milking in the parlor puts a strain on your back.

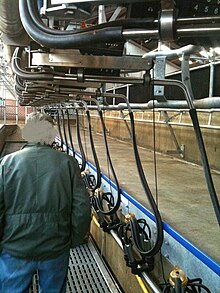

Herringbone milking parlor

In the herringbone milking parlor, the cows stand at an angle of around 30 degrees with their heads away from the milking parlor, so that the udders are in the milking pit without the cows having to walk too much around the corner. The herringbone milking parlor can be equipped with a quick drive so that the animals leave the milking parlor quickly after milking. One speaks, for example, of a double-six herringbone , meaning a herringbone milking parlor in which there are six milking stalls with one milking cluster on each side of the milking pit. Polygon or triangle milking parlors which represent special designs of the herringbone milking parlor are used less often . A polygon milking parlor has 4 milking stalls each arranged in a diamond shape. A trigon milking parlor is triangular when viewed from above with different numbers of cows on each side. As a result, three different jobs such as milking, preparation and driving can be carried out alternately without idling times.

Side-by-side

In the side-by-side milking parlor, the cows stand at a 90-degree angle away from the milking pit. The milker has access to the udder between the hind legs. The side-by-side milking parlor is also called a parallel milking parlor.

Tandem milking parlor

In the tandem milking parlor (also called auto tandem), the cows stand one behind the other along the milking pit. As with a tandem bicycle, the cows look in the same direction. Thanks to special gates, each animal has its own box, which makes milking easier on a farm with older and weak cows. This can prevent traffic jams in the milking parlor. In the conventional milking parlor the other animals would have to wait until the last cow has been milked out, in this case there is no problem in the tandem milking parlor. However, the distances for the milker are very long and the udder can only be reached from the side. The advantage is that the cows have a clear view of the milking pit. As a result, it is occasionally observed that the cows behave more calmly.

Swing over

If there is only one milking cluster per pair of stands on the opposite side, this is referred to as being equipped with an interchangeable cluster or swing-over milking parlor. The position of the cows can be different with this type of construction. A swing-over saves a little on investment costs, but it also reduces the number of cows milked per hour based on the number of stands. The milking clusters are attached to a movable arm and swivel to the other side of the pit at the push of a button. The milking line is laid above the milker. It is described as disadvantageous that it can take up to 3 minutes between the stimulation of the cows and the availability of a milking cluster. Thus the release of oxytocin decreases again. As with the pipe milking systems, there are also changed milk flow curves due to the high-altitude milking line. The highest milk flow (HMF), the highest minute milk (HMG) and the average minute main milk (DMHG) are significantly lower than in conventional milking parlors, as the main milking phase is extended.

Rotary milking parlor

In a rotary milking parlor, the animal enters a rotating platform on which the milking clusters are installed. After milking, the carousel has turned three quarters of a turn and can then be left again. A rotary milking parlor is only suitable for larger herds with more than 100 animals. You need a well-designed waiting room so that the animals can get to the milking stall with as little assistance as possible. The position of the animals on the site can be different. The milker can work inside or outside the carousel. Outside has the advantage that he is there quickly in the event of disturbances or if you have to drive animals to the milking parlor and you don't have to have an additional person on hand. However, with an indoor milker a better overview of the animals is guaranteed. The milker can deal with disturbances, e.g. B. take care of fallen milking clusters - he usually doesn't even notice this with the "outside milker".

automation

Milking parlors can be equipped with accessories to make work easier. The stimulation of the milk flow can be automated, as can the removal of the milking clusters and subsequent milking . The use of electronic identification systems ( transponders ) allows individual animal identification and extended data processing. By recognizing the animal, the milking results can be saved individually. In a herd management program , fluctuating milk constituents can then be observed, analyzed and evaluated on the PC. Additional information for the milking staff can also be displayed at the milking station. If so-called pedometers are used, the animals' movement activity can also be recorded and saved. This is used for oestrus observation . The recognition systems are built as continuous recognition or single-user recognition. In the case of passage detection, the sensor is mounted on an entrance gate. A detection for each milking stall increases the security during reading, but is considerably more expensive due to the increased effort.

See also

- Milk production , automatic milking system , milking machine , pipe milking system , bucket milking system

Web links

- LfL Bayern, comparison of milking parlors (PDF; 60 kB)

Individual evidence

- ^ Haus Düsse, waiting room

- ↑ Landwirt.com

- ↑ Polygon milking parlor

- ↑ Bachelor thesis on milking technology (PDF; 2.6 MB)

- ↑ De Laval on Side-by-Side milking parlor

- ↑ LfL Bayern, Martin Kühberger, Dr. Juliana Macuhova Analysis of swing milking parlors ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice. , pdf