Shoring

As shoring are structural measures and facilities for supporting and securing trench, pit, pit - and tunnel walls and tunnel walls and ceilings in the area of excavation, in gravure, called tunneling, water and mining. In Austria the term Pölzung is used for this , in Switzerland Spriessung .

task

The shoring secures a cavity against collapse, ground slipping, water penetrating or erosion and thus protecting traffic routes, pipelines, work space, equipment and people from danger and impairment. The execution and stability of shoring are the subject of the occupational health and safety regulations and are regulated by relevant standards.

The different cavities with their specific requirements lead to special techniques.

Mining (see pit construction ) has the longest experience and tradition in the execution of shoring, the major tunneling projects have contributed to the current advancement of technologies.

In the field of earthworks, structural and civil engineering and the laying of cables, the technologies used can be roughly differentiated according to two aspects: In trench shoring, the lateral safeguards support each other; in building pit shoring, the shoring is secured by back anchoring or clamping in the ground. A distinction is also made between the following types of shoring:

Types of installation

Girder pile wall

Berlin shoring

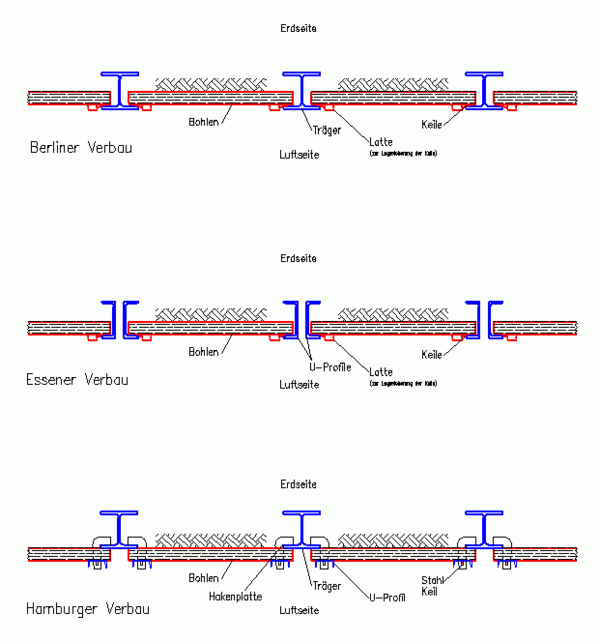

The classic Berlin shoring (see sketch above) is the most common variant. An IPB carrier , less often an IPE carrier, is used as the shoring carrier . The planks are arranged between the shoring girders, following the excavation, and are supported against the girder flanges. They are wedged between the beam and the floor. The planks are made of wood and, like the girders, can be reused during dismantling. In this case, there must be a working space between the structure and the pile wall. In rare cases and where space is limited, concrete planks can be installed instead of wooden planks. Then a work area can be dispensed with and only the shoring supports are drawn later. The concrete boards remain in the ground as they cannot rot. In the case of greater excavation depths, a horizontal bracing consisting of 2 adjacent U-profiles is arranged in front of the shoring beams, which are anchored back with grouted anchors or the like.

Essen shoring

The Essen shoring is similar to the Berlin shoring, only that the shoring supports consist of two adjacent U-profiles that are connected by brackets. In the case of greater excavation depths, an additional horizontal strap can then be dispensed with for back anchoring. The grouting anchors or similar can be arranged directly between the U-profiles.

Hamburg shoring

The Hamburg shoring differed from the Berlin shoring in that the planks were fastened. Here the planks are not arranged between, but in front of the shoring supports and anchored back to the shoring supports using slotted hook plates with short U-profiles or Schipplie iron. This type of construction is rarely used.

Shoring boxes

In the case of shoring boxes, two large-format steel shoring panels are placed as a complete unit in the trench that has already been dug and pressed against the trench end walls by spindles attached between them. In the case of soils that do not have sufficient stability even temporarily, the shoring boxes must be pressed into the soil as the trench excavation progresses.

Slide rail assembly units

Strut-supported slide rail pairs are set in the trench and then the shoring panels are inserted into the slide rails. This has the advantage that the installation depth can be adjusted during the construction work.

Bored pile wall

Depending on the type of pile wall, the boreholes are reinforced or unreinforced with in-situ concrete. This type of shoring particularly inhibits the earth's movement in the area. Back anchors are required from greater heights. A distinction is made between three construction methods (overlapping piles, tangent piles, detached wall with the possibility of escaping water).

Diaphragm wall (according to DIN 4126)

This type of shoring is a closed wall made of reinforced or fiber-reinforced concrete up to 100 m in height. Parallel to the excavation with a diaphragm wall grab , the open trench is filled with bentonite suspension. Then the reinforcement is lowered and the wall is concreted. The heavier concrete sinks to the ground, displacing the bentonite suspension, which is pumped out at the top.

Retaining wall

With this type of shoring, steel sheet piles are rammed or pressed into the ground next to one another. The edges of the planks are shaped so that they interlock. After driving, the construction pit can be dug. Depending on the depth, back anchors or stiffeners must be installed at certain intervals. Sheet piling can be made watertight.