Tunneling

The tunnel is the portion of the civil engineering , which underground with the preparation cavities ( tunnels , tunnels , shafts , caverns u. Ä.) Employed.

There are two basic types of construction. The open construction method can be used if there is little overlap . With a large overlap, the execution takes place in underground mining in a closed construction , partly on the operations of the mining is based. Today's modern forms of the closed tunnel are the shotcrete construction according NATM or the use of open or shield tunneling - tunnel boring machines . But there are also tunnels that are secured with stamps and shoring and then lumbered out / bricked up. Experience from the construction of barrel vaults is helpful here.

Main features

Tunnel construction is one of the most fascinating but also most difficult tasks in the construction sector. There are direct dependencies between the permanent tunnel structure, the excavation of the necessary tunnel cavity and the mountains to be crossed. The surrounding mountains are also used for the load-bearing effect, i.e. it becomes a building material. The excavation of the tunnel cavity usually takes place in mountain formations which, due to their formation, are layered differently, also folded and exposed in different ways to weathering and the ingress of water. With its material properties and their characteristic values, the building substrate shows large spreading widths, which the building processes and, above all, their safety measures must take into account.

“Tunnel construction unites theory and practice into an engineering art of its own. When weighting the many influences, depending on the level of one's own knowledge, the focus is either on practice or on theory. Engineering tunnel construction is now largely carried out by civil engineers, but everyone should be aware that knowledge of statics and solid construction alone is not enough. Geology, geomechanics, machine technology and, in particular, construction process engineering are equally important. "

requirement

Precondition for a tunnel construction project is the exact knowledge of the geological condition and strength of the mountain , the rock stratification and composition and its course as well as the water flow of the rock strata, the occurring pressures and the soil mechanical analysis. The delimitation of the clear space, thickness of the lining, sealing , water flow and ventilation are described in the "design cross-section".

In modern tunnel construction, fire protection issues in the form of escape routes , emergency exits , fire alarm and sprinkler systems are included in the planning at an early stage.

Definitions

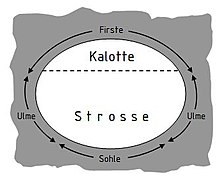

In tunnel construction, terms are used that come from mining and are therefore not generally understood. The graphic on the right shows the names for the tunnel cross-section.

- Dome - upper third of the tunnel cross-section

- Bench - lower two thirds of the tunnel cross section

- Roof ridge - ceiling of the tunnel

- Elm - side wall of the tunnel

- Sole - bottom of the tunnel

When excavating the tunnel cavity, i.e. the "shell of the tunnel", the following are common:

- Face - excavated cross section in the mountains

- Driving depth - possible excavation depth (in the longitudinal direction of the tunnel) without securing

The underground structures are divided into:

- Tunnels - elongated, horizontal or only slightly inclined underground cavities with more than 25 m² cross section, mainly as road or rail tunnels,

- Tunnels - elongated, horizontal or up to 20% inclined underground cavities with a cross section of less than 25 m², mainly used as water and air pipes, to accommodate pipes or as access to other underground structures,

- Shafts - elongated, sloping (more than 20% inclined) or vertical cavities for overcoming height differences, tasks similar to tunnels,

- Caverns - rock cavities with large cross-sections and a relatively short length, primarily as storage facilities, storage facilities or to accommodate machines, e.g. B. for hydropower plants.

Tunneling equipment

The following machines are used in tunnel construction:

- Equipment for dissolving the rock ( excavators , hammer drills, rotary percussion drilling , coal cutting machines , tunnel boring machines , shield driving machines ), disintegrants

- Devices for loading the rock (ballast belts, tunnel or shovel loaders , wheel loaders )

- Equipment for transportation of the rock ( Loren , railways , deep depression transporters , conveyor belts )

- Devices for concreting ( concrete pumps , concrete spraying machines , pneumatic concrete conveyors, formwork carriages )

Construction methods and driving

Basically, a distinction is made between the open construction method , also known as the cut and cover method, in which the tunnel is built from above, and closed or mining construction , in which the tunnel is driven from one or both end points.

Furthermore, in cyclical (NATM - New Austrian Tunneling Method and shotcrete method) and continuous driving with tunnel boring machines (possibly in the shield tunneling ) distinguished.

The breakthrough at which the two ends of the jacking meet is celebrated with a celebration.

Tunnel construction in solid rock

The eruption in cyclical tunneling is carried out by shooting (blasting), by dredging (excavating) or as a hybrid (mixed method of excavating and blasting); the loosened rock is then loaded onto conveyors with loading machines and transported away. The general excavation work includes drilling and blasting work, rock loading, removal of the spoil, the implementation of safety measures (tunnel or tunnel carpentry) and the lining .

Jacking is the designation for the construction method, but also the distance gained, which is specified in meters per day.

- In the traditional construction method , an alignment tunnel is driven into the mountains as a ridge or bottom tunnel . Then the rock is excavated in sections up to the extent of the entire cross-section. This is followed by securing against breaking and full expansion as further work steps. The traditional construction method requires a great deal of wood to secure it .

- In the modern full extension , exposed areas are secured by shotcrete , rock anchors , steel arches and other structural elements. The use of large, fully automated machines means that there is no need to fill the room. This method is also called the New Austrian Tunneling Method .

Tunnel construction in unstable rock

If the rock is not stable, the excavation is sometimes still carried out using the traditional but modified construction method. Almost without exception, the causes of unstable rock are so-called fault zones .

- Core construction

With the core construction method or German construction method , two lateral floor tunnels are first excavated as space for the abutments and a ridge tunnel, before one works one's way through the roof to the base tunnels. The solid core is only broken out after the tunnel wall has been completed.

- Belgian construction

In the case of underpinning or Belgian construction , you start with the expansion and support of the roof (= dome). This is followed by the execution of the abutment in sections by slitting the side from an alignment tunnel (= bench construction).

- Old Austrian construction

With the old Austrian construction method , a bottom tunnel is being driven forward and enlarged. This is followed by slitting up to the ridge. From there the full breakout takes place.

- Propulsion

In the case of tunneling or English construction , the full excavation takes place one after the other, which is followed immediately by the drawing in of the vault.

- Offset

In the case of the offset construction or Italian construction , one begins with the breakout of the lower third and the immediate pulling in of the lower abutment part and sole vault.

- Ring construction

One of the modern construction methods is ring construction , which begins with breaking out and clearing out the dome. This is followed by the laying of multi-part ring sleepers, the ring being formed by a base or ring sleeper, teaching arch, rider and breakout arch. After the sprayed concrete has been applied, the bench can be cleared out and the base vault produced.

- Knife construction

The knife construction uses steel, pointed canal boards that secure the roof and are driven at the edge of the vault as jacking knives while driving the tunnel face into the mountains at the same time . The vault is produced in sections.

- Shield drive

With the shield driving method , which is used in loose rock, a steel cylinder known as a cover shield is driven in the cross section of the later tunnel profile with hydraulic presses, which in turn are supported against the finished vault. In its protection, the tunnel tube can be cleared out using a rotating tiller in the driving process and secured with rock anchors and shotcrete. In the next work step , the vault is lined with concrete or steel tubbings after the presses have been pulled in . In the case of water-bearing rock layers, the work area can be closed off with a rear wall and placed under overpressure so that no water penetrates.

- Freezing process

In the freezing process , bores are made in a ring around the future tunnel, in which a coolant circulates and the surrounding rock freezes. The tunnel can then be driven without the surrounding mountains collapsing.

- Tube umbrellas

Tubular umbrella ceilings are used to pass under heavy structures, with thick steel pipes being driven under the foundations and filled with reinforced concrete. Occasionally water-saturated, floating concrete is frozen or petrified before the eruption.

Open design

The open construction method is used when there is little overlap. A typical area of application is under paving in densely built-up old towns. However, mining is increasingly being used there in order to avoid traffic obstructions and nuisance to residents and to save the relocation of supply lines.

- With the conventional open construction method , the excavation remains open during the entire construction period. The lateral sheeting walls are driven down before or during the excavation.

- With the cover construction method, bored piles or diaphragm walls made of reinforced concrete are erected, between which the construction pit is excavated. As soon as the height is reached at which excavators and wheel loaders can work, the pit is covered to keep the traffic flowing over it. The cover construction is used in the construction of paving strips.

- The floating and lowering technique is rarely used in Germany to cross bodies of water . Here, prefabricated caissons (caisson method) or tunnel sections are floated in on land and sunk into the flushed river bed. Example: Warnow tunnel

Assessment of the rock for tunnel construction

The basis for the design and calculation of the tunnel structures, for the selection of the excavation method and for the selection of the temporary excavation protection during construction are:

| Mountain classes |

Standing time | Representative mountain species |

Standing time with unsecured span duration | length (m) |

Mountain behavior and security |

Shotcrete | |

|---|---|---|---|---|---|---|

| A. | Steadfast | 20 years |

4th | not required |

||

| B. | Resilient |

Quarzphyllite chlorite Kalkglimmer- slate |

0.5 years |

4th | Slight breakouts |

2 to 3 cm in the head area |

| C. | Easily used |

Dolomite in fault strips |

7 days |

3 | Initial stability, cracks after months |

3 to 5 cm in the head area |

| D. | Use |

Clay marl crumbly sandstones |

5 hours |

1.5 | Steady at breakout , later strong breakouts |

5 to 7 cm, in the head area with structural steel mesh |

| E. | Very usable |

Marly sandstones, clay mica schist, hard marl, limestone schist |

20 min. |

0.8 | At the outbreak of severe loosening, localized First breaks |

7 to 15 cm with structural steel mesh |

| F. | Powerful |

Shale shale marl mountain moist clay |

2 min. |

0.4 | Very tight and heavy securing required |

15 to 20 cm with structural steel mesh supplemented with steel arches |

| G | Very powerful |

Slate, crumbly marl |

10 sec. |

0.15 | Advance backup |

stiffened steel arches, subsequently shotcrete |

- The results of the preliminary explorations with exploratory drilling,

- The qualitative and quantitative description of the rock based on this with material parameters,

- Hazard pictures and risk analyzes.

Three classification systems are used to assess the rock , which achieve this assignment with the question of how, when and what :

- How the mountains react to the eruption is described by the behavior of the mountains with hazard profiles such as falling rocks, collapses, rock falls, bed elevation, narrowing of the cross-section and water or gas leakage.

- When the rock reacts with breaking rock (post-breakage), the standing time after the breakout of the cavity indicates.

- What to backup and expansion measures is required, the classification of the mountain range describes to take precautionary measures.

The first two groups assign the properties that occur and limit the measures that can be selected in the third group, as the overview table shows. See also

Execution of underground structures

Organizational forms

There are three types of organization in the construction industry that can be used to create underground structures:

- In the case of the organizational form of the individual service provider, the client searches for a suitable construction company within the framework of a tender with a detailed list of services and specification of the excavation and tunneling classes. This is the most frequently used form of organization in underground mining.

- The second form is the general contractor model, in which the overall performance in a functional tender with a performance program with general specifications and the like. a. for breakout classes and accounting systems.

- The third form consists of the assignment to a general contractor with a functional tender. The general contractor pulls together suitable construction companies for the construction task and is usually not involved in the construction, or only to a small extent. So far, this form has only been chosen in a few cases in underground mining.

Planning and execution phases

The services in a project implementation with a single service provider run in the planning and execution phases in the following way with clearly defined task assignments: In the concept phase , the client first creates preliminary studies, which are processed more precisely with the preliminary design and then in a concept and feasibility study The basis for decision-making for this planning phase. The next step is geological studies and a first compilation of the costs as a cost estimate with a customary accuracy range of ± 30 to 50%.

This is followed by the construction project phase, in which more extensive subsoil investigations are carried out, geological and ecological reports are drawn up and a rough division into excavation classes is carried out.

This is followed by the approval procedure, usually as a plan approval procedure. The main approval requirements for further planning and execution are specified in the planning approval decision. This includes in particular the guarantee of environmental compatibility and the protection of the interests of third parties. The permit conditions supplement the description of services in the following tender.

In the construction project phase, the implementation planning is created and refined on the basis of the documents that have been working so far. In this phase, supplementary subsoil examinations are usually necessary in order to clarify open questions for drawing up the specifications. The jacking process and the associated securing as well as the division of the structure into excavation classes are specified in the specification of services. With this form of organization of the individual service provider, the builder largely specifies the construction process, the construction of the structure and the construction process. It grants a certain leeway for suggestions of alternative construction processes or expansion methods, which can be submitted by the providers as special suggestions as part of the offers.

After the tender, the associated price competition and the award of the contract, the building contractor carries out the individual construction phases. If special proposals have been commissioned, it may be necessary to adapt the existing approval with a plan change procedure. The building contractor is responsible for the correct choice of equipment and processes resulting from the specified construction methods and the correct treatment of the subsoil. The building contractor notifies the client of any changes in geological conditions, who then decides on changes to the excavation or security classes.

Advantages and disadvantages of executing with a single service provider

As an advantage of this form of organization, the client can individually influence planning and execution, especially quality and thus also the price. In the event of plan changes, the agreed specification of services provides a good basis for mutual processing. This is particularly important if the geology or the permit requirements result in imponderables. Another advantage of this method is that the tendering can be used to make use of price competition between the companies offering it.

As a disadvantage of the organizational form of the individual service provider, there is still the financial and scheduling risk for the client. The basic risk of the subsoil remains with the client, regardless of the organizational form, since he “makes the subsoil available” and is therefore responsible for the condition - principle: “Subsoil is the owner's risk”. This is particularly important in tunnel construction, as the surrounding mountains become part of the structure. If there are differences between the condition actually found and the agreed specification of services, the resulting expenses shall be borne by the client.

With this form of organization, the client is also responsible for coordinating the interfaces to the other service providers. The step-by-step processing of the planning phase before execution does not allow for an accelerated project execution, which usually results in a long project duration. Due to the specification of the tunnel construction methods, special knowledge and methods of the contractor can only be used to a limited extent within the framework of the special proposals mentioned, which do not allow any fundamental changes. Due to the pure price competition, the entrepreneur is usually interested in increasing his often narrow profit margin by requesting supplements and improving the economic viability of the project.

With the organizational form of the individual service provider, it is advantageous for the entrepreneur that he does not have to bear any risk from deviations in the service description and, in the case of a uniform price contract, receives remuneration for all services performed, including the aforementioned changed or additional services.

See also

- Tunnel stop

- Foundation

- Engineering geology

- Civil engineering (mining)

- Girder pile wall

- Reinforced earth

- List of the longest tunnels in Germany

- List of the longest tunnels on earth

- List of alpine tunnels

- List of tunnels in Germany

- List of Swiss tunnels

- List of tunnels in Austria

literature

- W. Schubert, A. Fasching, A. Gaich, R. Fuchs: New methods in data acquisition and display in tunnel construction . In: Unterirdisches Bauen 2000. Challenges and development potential . STUVA conference 1999. STUVA, Cologne 1999 ( 3-g.at [PDF; accessed on May 18, 2014] short version).

Web links

- Table of all German railway tunnels, sorted according to various criteria

- Historic train tunnel in the Alps

- It's dark in front of the hoe - article on innovations in tunnel construction on the geosciences portal planeterde

Individual evidence

- ^ A b c d Gerhard Grimscheid: Construction operation and construction methods in tunnel construction . 2nd Edition. Berlin 2008.

- ↑ Bernhard Maidl: Manual of tunnel and gallery construction, Volumes I and II . 3. Edition. Essen 2004.

- ^ German Society for Geotechnics eV: Recommendations of the working group "Tunneling" - ETB . Ernst & Son, Berlin 1995.