Girder pile wall

A girder pile wall (also known as a girder pile wall) is a construction pit sheeting that prevents the ground from sliding down into a construction pit . The term Rühlwand is common in Switzerland . In addition to the pile wall, other shoring techniques , such as diaphragm wall , bored pile wall or sheet pile wall , are also possible.

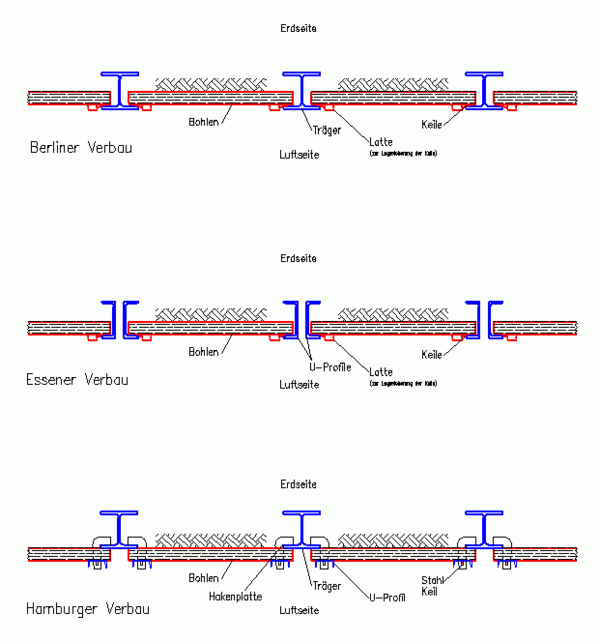

The pile pile wall is available in various design variants that differ in terms of their design, the material used and the type of installation. The best known is the so-called Berlin shoring. The name is derived from the first use in the 1930s for the construction of the Berlin subway . The term Berliner Verbau is often used as a synonym for “girder pile wall”. Design variants are the so-called Essen shoring and the Hamburg shoring .

production method

The construction of a pile wall is carried out in several steps:

First, vertical beams (approximately 1.5 to 2.5 meters) along the future excavation edge at regular intervals drilled . In the Berlin shoring, wide-flange girders of the type HEA or HEB are usually used , alternatively U-profiles connected via brackets . In the case of loose soils, the girders are usually shaken in (vibrated in) and then rammed in earlier. To reduce noise and vibrations, it is mostly common in urban areas to make cased holes into which the beams are placed. Concrete feet can also be used for the girders to increase the deformation rigidity. Concrete feet may also be required for anchored walls to derive the vertical component of the anchors.

Then the excavation begins, with stiff and cohesive soils down to a depth of approx. 1.25 meters. In the case of unfavorable soil conditions, it may be necessary in extreme cases that the advance excavation is only one screed width. Then squared timber or wooden planks are placed between the exposed flanges of the steel girders and pressed against the ground with wedges. As an alternative to using wood, the infill can also be carried out with shotcrete , reinforced concrete, reinforced concrete prefabricated parts or steel elements ( duct boards ). Basically, for the installation of the horizontal infill (wooden planks, shotcrete) it is necessary that the existing soil is temporarily stable until the exposed shoring area is built again. If the floor is to be installed in floors that are not temporarily stable, the floor must be strengthened or consolidated (for example with injections). Alternatively, vertical infills can be made in advance with duct boards or sheet piles.

Depending on the subsoil parameters and taking into account the traffic and structural loads, anchoring of the girder pile wall by means of grouting anchors or bracing to the opposite sheeting wall is usually necessary from a construction pit depth of 2 to 3 meters . In deep excavations, the pile wall is anchored or stiffened on several levels.

In many cases, the pile wall is dismantled after the construction work has been completed. The infills will be expanded step by step and the excavation will be filled. The carriers themselves can be drawn at the end. Re-use is possible. The anchoring remains in the subsoil. Often, however, the wood is left in the ground and rot. After approx. 20 - 25 years there is considerable subsidence in front of the building which has to be extensively renovated.

Areas of application

Girder pile walls are ideal for securing construction pits and for building canals of medium and greater depths, even with complicated floor plans. However, the prerequisite is that the bottom of the excavation pit is above the groundwater level . During the extensive use of the construction method in Berlin before the Second World War for underground and suburban railway construction, the groundwater level was lowered with powerful pumps, which, however, led to damage to the neighboring buildings, particularly those with wooden pile foundations. With the appropriate design, the pile wall can also be used as a permanent safeguard, although wood infills are not suitable for this use.

variants

There are different variants of the pile pile wall, which differ in design but are similar in principle.

- The classic Berlin shoring (see sketch above) is the most common variant. An IPB carrier , less often an IPE carrier, is used as the shoring carrier . The planks are arranged between the shoring girders, following the excavation, and are supported against the girder flanges. They are wedged between the beam and the floor. The planks are made of wood and, like the girders, can be reused during dismantling. In this case, there must be a working space between the structure and the pile wall. In rare cases and where space is limited, concrete planks can be installed instead of wooden planks. Then a work area can be dispensed with and only the shoring supports are drawn later. The concrete boards remain in the ground as they cannot rot. In the case of greater excavation depths, a horizontal bracing consisting of 2 adjacent U-profiles is arranged in front of the shoring beams, which are anchored back with grouted anchors or the like.

- The Essen shoring is similar to the Berlin shoring, only that the shoring supports consist of two adjacent U-profiles that are connected by brackets. In the case of greater excavation depths, an additional horizontal strap can then be dispensed with for back anchoring. The grouting anchors or similar can be arranged directly between the U-profiles.

- The Hamburg shoring differs from the Berlin shoring in the type of construction. Here, the planks are not arranged between, but in front of the shoring supports and anchored back to the shoring supports using slotted hook plates with short U-profiles or Schipplie iron. This type of construction is rarely used.

Advantages and disadvantages

Girder pile walls can be easily adapted to any floor plan. Recesses for built-in floors are relatively easy to make. Except for the ground anchors, the girder pile wall can be completely dismantled so that no construction aids remain in the ground. A pile wall is often the most cost-effective form of shoring.

If there is groundwater and it is not possible to lower the groundwater, pile pile walls can no longer be constructed. In contrast to diaphragm and bored pile walls, girder pile walls are counted among the "soft" construction pit structures. Due to the process, settlement is to be expected in the area of influence of this type of shoring, because the infill can hardly be installed over the entire surface and frictionally against the standing floor and the load-bearing steel girders deform. If buildings are in the area of influence of the shoring, the mutual influences must be statically examined in order to avoid damage.

literature

- Bernhard Wietek : Basic construction - introduction to theory and practice . MANZ Verlag Schulbuch GmbH, Vienna 2002, ISBN 3-7068-1206-1

Web links

- Paul Christiani: Definition of girder pile wall (PDF, 14 pages)

Individual evidence

- ↑ DIN 4124: Construction pits and trenches - embankments, shoring, working area widths