Jet grouting

The jet grouting method ( DSV ) is a form of soil injection for creating cement-soil mixture bodies in the ground. Here, the existing soil is mixed with a cement-containing binder suspension under high pressure. Other common, but non-normative, names are high-pressure soil mortaring (HDBV) , high-pressure injection processes (HDI processes) , jet grouting and company-specific names such as Soilcrete process or "RODINJET".

Procedure

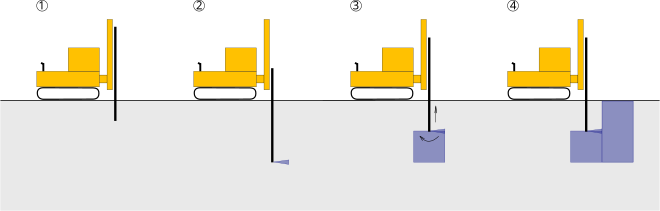

To produce a DSV body, an injection lance is first drilled into the ground. As a rule, a mud-assisted wet drilling process is used for this. After reaching the final depth, a mineral binding agent suspension is injected into the soil at the tip of the lance under high pressure (pressures up to 600 bar , exit speed> 100 m / s). The sharp beam cuts the pending soil material. The soil is eroded and mixed with the binding agent suspension, which then forms a concrete-like body with the natural soil as an aggregate .

As binder one will suspension on cement base used, yet the bentonite and, as required, various chemical additives may be added. Bentonite reduces the strength of the concrete, but has the effect that the fresh concrete is waterproof and the binding agent cannot be washed out, which is particularly important when the groundwater is flowing .

Depending on the method used, the suspension is injected through a single nozzle (simplex method) , a binding agent jet sheathed with compressed air is used (duplex method) or the soil is cut open with a water jet sheathed with compressed air and the ground is pre-eroded in this way Binder injected with a low pressure (triplex process) . The advantage of this third method is the lower pressure of the binding agent and the consequent lower wear on the device (especially the nozzle head).

After starting the injection, the lance is pulled slowly while turning continuously. The soil is cut open in a helical shape and a cylindrical concrete-like body is created. However, any desired shapes can also be produced by varying the device settings.

Column diameters of 3 m and more are possible, depending on the nature of the soil and the device used, or the energy introduced into the soil during the manufacturing process. DSV columns can be manufactured vertically, inclined or horizontally. By lining up standing or lying panes and walls as well as three-dimensional bodies (e.g. tunnel profiles) can be produced.

The achievable quality of the concrete-like solidified bodies depends on the grain distribution of the soil (the finer-grained, the more soil has to be discharged with the backflow in this process, which is comparable to flotation, and the lower the achievable strengths, usually significantly less 6 MPa). Incidentally, the DSV body - if produced in gravelly soils - can certainly correspond to C12 / 15 quality concrete.

application

The jet grouting process can be used for a variety of applications. Basically, the DSV bodies have both a static and a sealing effect. Some application examples are

- The undertaking of foundations for existing buildings.

- The creation of tight construction pit structures .

- The sealing of excavation bases.

- The stabilization of problematic soils in tunnel construction using a DSV screen.

- The erection of sealing screens for dams etc.

advantages

One advantage of the jet grouting method compared to conventional soil injections is that DSV bodies can be produced up to just below the edge of the terrain without the risk of elevation if the procedure is careful. In some applications, an elevation of the building by the DSV is also desirable.

Compared to other methods of securing construction pits or underpinning work, only comparatively small devices are required for the jet grouting method, which can also be used inside buildings if necessary.

literature

- DIN 18321: Jet grouting - September 2016 edition - Part of VOB / C

- DIN EN 12716: Execution of special geotechnical work (special civil engineering ) - jet grouting

- ÖNORM EN 12716: Execution of special geotechnical works (special civil engineering ) - jet grouting

Individual evidence

- ↑ Basement foundation

- ↑ Rodio

- ↑ Burke