Shield drive

The shield tunneling is a construction method of the tunnel , in which the tunnelvortreibenden workers and machines (z. B. excavators, mills, tunnel boring machines (one or mehrgliedrig)) through a plate to be protected. This mechanical process is primarily used in tunnel construction in unstable and weathered rock formations.

history

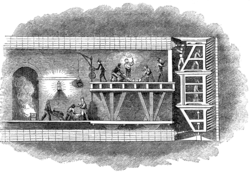

The shield tunneling was developed by Sir Marc Isambard Brunel , a French emigrant, and Thomas Cochrane for the construction of the 400 m long Thames Tunnel under the Thames in London (1825–1843). He was inspired by the shipworm ( Teredo navalis ), a clam that digs its way in front with the rasps - shells that have receded into teeth - and secures it behind with a tube of the body's own calcareous secretions. As a saltwater inhabitant, she bores her way through ship's wood, hence the name.

Based on this principle, the engineer developed a construction method - digging at the front and securing it at the back - which he patented in 1818. He was pursuing an ambitious project with her: in the middle of London, he began to build a 400-meter-long tunnel with two shields under the Thames. His method still used a rectangular box with open sides, in which workers worked side by side and on top of each other on the "jacking wall " ( face ) while the side walls were bricked up. The jacking box was always moved a little further.

A number of technical problems and water ingress led to considerable delays and ultimately made the project a financial disaster. Although the tunnel itself was completed in 1843 after almost 20 years of construction, there was not enough money for access roads and the construction of the route to bring the newly flourishing urban rail traffic. The East London Line , a line from London Overground , now crosses under the Thames in the renovated tunnel .

The method was further developed by Sir Peter W. Barlow , who was commissioned in 1869 with the construction of a Thames tunnel for the London Underground . Instead of a box, he used a round jacking plate, and the support was no longer provided by masonry, but by iron segments that are screwed together - these support segments are the forerunners of today's segments . His assistant James Henry Greathead continued to improve the technology ( Tower Subway ) and invented the Greathead Shield named after him, with hydraulic presses for propulsion and overpressure to prevent water ingress.

Procedure identifier

A tunnel boring machine for shield driving has the following assemblies, which are surrounded and thus protected by the shield, a steel tube-like construction:

- Dismantling sign with feed and tensioning devices

- Facilities for the installation of support and expansion measures

- Equipment for material removal (shear systems)

- Supply unit (electricity, compressed air, ventilation , water)

- Transport equipment for excavated material, proppants and finishing materials

The tunnel lining - mostly made of precast concrete parts ( tubbings ) - is installed under the protection of the rear shield jacket, the so-called shield tail.

Structure and types

According to the ÖVBB Shield Driving Directive from 2009, shield machines belong to the tunnel driving machines (TBM). These are classified as follows:

|

Work steps in shield driving

In shield driving, a distinction is made between partial and full-surface excavation. In the case of partial excavation, cutting arms are used, similar to those on partial headers . In the case of full-surface excavation, a rotating cutting wheel is used as with tunnel boring machines, see section "Work steps in tunneling" there

The work sequences are shown in the short film tunnel boring machine on the AlpTransit Gotthard AG website.

Manufacturing companies and machine development

Well-known projects

Selection, further examples see p. Main article tunnel boring machine

- City-Tunnel Leipzig (rail connection - S-Bahn and long-distance traffic)

- Finnetunnel (new line Erfurt - Halle / Leipzig) (Germany)

- TRUDE ( A7 motorway , fourth Elbe tunnel tube, Hamburg)

- Wienerwaldtunnel (railway connection, Austria)

Web links

- Herrenknecht - manufacturer of shield tunneling machines

- Shield driving as part of the local transport project of the Kölner Verkehrs-Betriebe AG

- Shield driving as part of the local transport project of the Düsseldorfer Rheinbahn AG

- Shield driving as part of the Leipzig City Tunnel

- Short film tunnel boring machine

Individual evidence

- ↑ Dietmar Adam: Tunnel construction in solid and loose rock , TU Wien, 2016, p. 132 ff.