Polybutadiene

| Polymers from 1,3-butadiene (schematic presentation) |

| Section from a polymer chain of cis -1,4-polybutadiene. A C 4 unit is circled in blue . |

| Section from a polymer chain of trans -1,4-polybutadiene. A C 4 unit is circled in blue . |

| Section from a polymer chain of isotactic 1,2-polybutadiene. A C 4 unit is circled in blue . The vinyl groups can be seen in the side chains . |

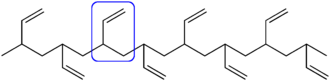

| Section from a polymer chain of syndio tactical 1,2-polybutadiene. A C 4 unit is circled in blue . The vinyl groups can be seen in the side chains . |

Polybutadiene is a collective name for homopolymers made from 1,3-butadiene . Polybutadiene one of the synthetic rubbers and also as a butadiene rubber ( abbreviated BR from English butadiene rubber referred to).

In terms of global consumption, polybutadiene is the second most important synthetic rubber, accounting for about a quarter of the market volume in 2012.

Manufacturing

Polybutadiene can be produced by means of anionic, coordinative or radical chain polymerizations . Depending on the type of polymerization, polybutadienes are formed with structural units that appear differently. The CC double bonds in the repeat units can occur as 1,4- cis , 1,4- trans or 1,2-units. A 1,2-unit corresponds to a vinyl group , the double bond is in the side chain.

Free radical chain polymerization : Emulsion polymerization leads to a random occurrence of the three sequences. At a low reaction temperature (5 ° C) the proportion of vinyl groups decreases. Initiation takes place with potassium peroxodisulfate and iron salts. With hydrogen peroxide as the initiator , short-chain macromolecules can be produced, which lead to terminal diols through initiation and termination reactions with OH radicals ( telechelic ). As diols , they are used for the synthesis of elastomeric polyurethanes .

Anionic chain polymerization : The chain polymerization is initiated with butyllithium . The polybutadiene obtained in this way contains about 40% 1,4- cis and 50% 1,4- trans units. In this way, however, butadiene is preferably converted to copolymers, such as styrene-butadiene rubbers , styrene-butadiene-styrene block copolymers or acrylonitrile-butadiene-styrene copolymers .

Coordinative chain polymerization : The stereospecific Ziegler-Natta catalysts lead to a polymer with a high proportion of 1,4- cis units. Vulcanizates of this polymer are used as elastomers .

Polymerization cis -1.4 units (%) trans -1.4 units (%) 1.2 units (%) Neodymium coordinative 98 1 1 Cobalt coordinative 97 1 2 nickel coordinative 97 2 1 titanium coordinative 93 3 4th Butyllithium anionic 36 to 38 52 to 53 10 to 12

Polybutadiene has a high elasticity and can be used in the temperature range from - 80 ° C to 90 ° C. Even without fillers, polybutadiene has good strength (similar to natural rubber) and excellent abrasion resistance, and when filled and vulcanized it also has a high resistance to cracking.

use

To improve the properties and processability, polybutadiene is mixed with natural rubber or styrene-butadiene rubber SBR. It is used in car tires and golf ball cores .

Individual evidence

- ^ MD Lechner, K. Gehrke, EH Nordmeier: Makromolekulare Chemie. 4th edition. Birkhäuser Verlag, 2010, ISBN 978-3-7643-8890-4 , p. 29.

- ↑ Arne Peters: Elastomer market with perspective. ( Memento of the original from July 14, 2014 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. In: K newspaper. June 24, 2013.

- ↑ Bernd Tieke: Macromolecular Chemistry. 3. Edition. Wiley-VCH, Weinheim, 2014, p. 93.

- ↑ Bernd Tieke: Macromolecular Chemistry. 3. Edition. Wiley-VCH, Weinheim, 2014, p. 114.

- ↑ Bernd Tieke: Macromolecular Chemistry. 3. Edition. Wiley-VCH, Weinheim, 2014, p. 149.

- ↑ Dirk Steinborn: Fundamentals of organometallic complex catalysis. Vieweg + Teubner, Wiesbaden 2010, p. 232. (Restricted preview)