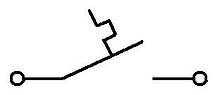

Temperature switch

A temperature switch or thermal switch is a switch whose switching status changes depending on the temperature . Components that are a temperature switch are often referred to as a thermostat .

Types, structure and function

Bimetal switch

Use as a temperature switch

The essential element of a temperature-controlled bimetal switch is a bimetal strip or plate (composite of two metals with different coefficients of thermal expansion , see bimetal ). The strip bends and actuates a snap switch , corresponding curved plates themselves have a jump behavior ( concave curvature suddenly becomes convex ), so that a subsequent snap switch can be omitted with these switches.

The switches cause the circuit to open or close , whereby a process (heating, cooling, pumping, etc.) can be started or stopped.

Small round bimetal switches with snap action are used to manufacture NC and NO contacts for various fixed nominal and switching temperatures in the range from 50 to 250 ° C. They often have flange mounting so that they can be mounted with good thermal contact on the surfaces to be monitored.

In kettles , for example, they trigger the automatic switch-off, namely when the boiling temperature is reached .

Use as an overcurrent sensor or switch

Bimetal switches in strip form are also manufactured with a heating wire wrapping; they then serve as a trigger in overcurrent switches by reacting to the heat of the load current flowing through them (for example in motor protection switches and automatic circuit breakers ). Such bimetallic switches can work very precisely because the resulting heat of the current increases with the square of the current flowing through it, i.e. very steeply.

Sometimes the load current also flows directly through the bimetal, which, depending on its shape, must then have a defined electrical resistance. However, it does not support the switching contact itself, since otherwise the non-constant contact resistance would have an influence on the switching threshold.

Designs with curved bimetallic disks with jump behavior are also manufactured, with these the heating wire is housed next to the disk in the form of a spiral (for example overload switches on compressors of refrigerating machines ).

Bimetal overcurrent switches and PTC fuse elements must always be supplemented with short-circuit protection (for example a fuse or the magnetic release in miniature circuit breakers ).

Strip-shaped bimetal switches that work with a high-resistance heating coil are called bimetal relays ; they are no longer in use today and were used for time-delayed switching.

Designed as a thermal fuse

Thermal fuses or short thermal fuses are self-resetting or irreversibly triggering safety elements for disconnection of circuits at high temperature. You work with bimetals , PTC thermistors or with a low-melting metal with a defined melting temperature ( Woodmetall ).

Temperature switch with liquid

Liquid-filled temperature switches use the thermal expansion or evaporation of a liquid. The liquid is in a hermetically sealed vessel, a pipe connected to it and a pressurized can. The pressure cell actuates the switching contact. The pipe connection can have a certain length (up to approx. 2 m) so that the switch can be located away from the measuring point. Such temperature switches are manufactured for temperatures from −20 to approx. +300 ° C.

A refrigerator thermostat works on this principle. A capillary tube contains an easily evaporable liquid which, depending on the temperature, acts on the switch via a membrane of a pressure cell . The sensitivity and thus the desired temperature range can be set using a rotary knob. This changes the distance between the membrane and the switch or the switching pressure. The actual temperature measurement takes place at the end of the capillary tube.

In principle, contact thermometers are also temperature switches, but they are not designated as such.

Other designs

I.a. In irons, stoves and electric boilers you will find temperature switches that use the different thermal expansion of different materials without forming a bimetal. Rod-shaped temperature switches in boilers use, for example, a glass rod located in a metal tube and its lower coefficient of thermal expansion than the tube.

The temperature monitoring of ceramic hobs also works according to this principle.

In newer irons , a slightly curved sheet metal strip attached on both sides above the cast aluminum base body, which expands rapidly with temperature, is used to determine the temperature, which actuates a snap switch for the heating.

use

Examples of the use of temperature switches are:

- Iron , oil radiator : if the set temperature is exceeded, the electrical heating is switched off, if the temperature falls below it, it is switched on again (adjustable bimetal switch)

- Kettle , toaster : If a temperature set, depending on the device, is exceeded, the electric heating is switched off permanently. Switching on again is only possible when the user actuates the switch again mechanically.

- Overtemperature protection: if a certain temperature is exceeded, a warning is triggered or cooling is switched on (fixed-value bimetal switch)

- Temperature controller in the oven or refrigerator: the heating is switched off or the cooling is switched on when a certain temperature is reached (adjustable liquid thermostat switch )

- by electricity heated bimetallic switches are in circuit breakers , overload switches and motor protection switches used.

literature

- Günter Boy, Horst Flachmann, Otto Mai: The master's examination in electrical machines and control technology. 4th edition, Vogel Buchverlag, Würzburg, 1983, ISBN 3-8023-0725-9

- Günter Springer: Expertise in electrical engineering. 18th edition, Verlag - Europa - Lehrmittel, Wuppertal, 1989, ISBN 3-8085-3018-9