Red Tag Analysis

The red tag analysis is a sorting process of lean management .

definition

The red tag analysis enables us to separate useless from useful things and is often used to create order in the workplace. This method is simple, does not require large financial resources or training, only an appointment has to be made for everyone involved. By sorting out, waste can be identified and eliminated, and an after-sales area can be identified. In addition, additional space is gained for the important things. It becomes clear which items are worth keeping in stock at all times and which items make more sense to order as needed. This can avoid tying up capital .

Origin and history

This technique of recognizing and avoiding waste originally comes from Japan. At the end of the Second World War, there was a severe shortage of raw materials in Japan and other countries did not offer any support either. The Toyota owners saw themselves forced to develop a new concept that saved resources in the right places and made work more efficient. So they developed the Toyota production system , which has proven itself to this day. The red tag analysis is a step in the application of the 5S system , which makes up a large part of the Toyota production system. The Japanese divided this lean management method into the following 5 sub-points:

- Seiri

- Seiton

- Seiso

- Seiketsu

- Shitsuke

The first point, the Seiri, is the procedure to create order and thus to lay the foundation for all subsequent points. The Red Tag Analysis is a useful tool that can be used to bring a structure into the sorting out.

method

A red tag analysis is best performed during a kaizen event. Kaizen comes from Japanese and consists of two words. "Kai" stands for "good" and "Zen" for "change". Kaizen is part of the Six Sigma system and is mainly used to describe a method of quality management . In a company it often happens that a new team is formed for a project. The selected team members come from many different areas of work and everyone initially considers their own work items to be indispensable and useful. However, items are sure to accumulate that are not of much use for this particular project and will act more like a waste of space. So before something new can arise, old structures and habits have to be broken.

Red day

During the Red Tag Analysis, unnecessary elements are removed from a workspace. Teams are often created on an ad hoc basis , with the potential for accidentally removing items that are actually needed for production. The red tag analysis helps to avoid these sorting errors. The general procedure for a red tag analysis is as follows:

- An employee identifies an item as possible waste and questions it.

- He fills out the "Red Tag" and attaches it to the said element.

- The person is waiting. There are no exact waiting times, but a period of up to 30 days is recommended.

- If another employee is of the opinion during this time that the "red tag" is unjustified, the two of them discuss and make a decision as to whether the marking remains or not.

- If it is decided to keep the element after all, the “red tag” is removed again.

- If it is decided to keep the element marked, it will be transferred to the so-called "Red Tag Area". This location refers to an area that stores usable but currently unused items. Another team may need this very element.

- Elements that were not even discussed about their use or their maintenance are completely removed. This can be done by selling the devices, giving them away to employees, auctions or scrapping them.

If the “red tag” was removed from an element and it was decided to keep it, a new place should be made for it. It is brought to the place where it is needed and its use is marked. This prevents future teams from marking the item over and over and then keeping it.

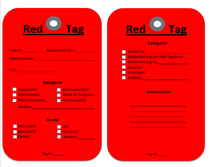

The so-called "red tags" can be bought ready-made, so no time has to be spent creating and printing them. Figure 1 shows an exemplary "Red Tag".

At the top of the front, the date on which the element was marked and next to it the name of the person who made the mark is entered. Then the name of the element and where it was found is given. In the categories you can tick which affiliation this element has. In addition, it must be ticked what reason the person sees to sort out this element, whether it is, for example, a defective element, whether it is simply not needed at the moment or whether it is simply out of date and no longer up-to-date.

After the waiting period has expired, a cross is made on the back to indicate what should ultimately happen to the element. Should it be returned to the workplace, be given a place in the red tag area or disposed of, etc. In addition, there is space on the back for comments and suggestions, if required.

Red tag area

A red tag area is simply a storage location for the items marked with the red labels. If this space is clear, it is also easier for employees to sort out items, as they know that they can still access them quickly if necessary. It also makes sense for the team leader to familiarize himself with the inventory of the red tag area at regular intervals in order to always have a rough overview and to be able to guide employees more quickly to the required target object. It is important that there should also be a time limit in the red tag area. A person who takes over the administration of this area regularly checks how long the objects have been in the red tag area. It determines their general usefulness, inherent value, and likelihood of future use. For example, a computer monitor should be kept until it is no longer up to date. A brand new LED sunpanel high performance LED blinder, on the other hand, should not even be included in the red tag area, as there is simply no likely use for it, even if it is an expensive item.

Large and expanded companies often keep it that way, that they list the items of the red tag area in a catalog. This reduces the likelihood that employees will purchase one of these items when the company already owns it. It is important to always remember that if items have been moved to the red tag area, they can still be of potential use to another member of the company and the red tag area cannot be used as a convenient way to store useless items of no value to dispose of, should be understood.

application areas

The red tagging method can be used in many areas. It is important that the structure and system are always cleared out, otherwise it becomes confusing. Be it at your own workplace, starting at your own desk, through your personal clipboard, physically and electronically, through shared files and archives, which can include the data jungle, to shared rooms, for which hardly anyone feels responsible, like large meeting rooms and conference halls.

In general, this method is used in the direct working environment, i.e. at the workplace or within the department, since it is there that it brings the most benefits. However, if there are discrepancies in the communication between employees and interfaces, joint identification of waste is not recommended. First of all, it should be ensured that there is an impeccable flow of information and exchange and that the Lean approach is supported by all employees, otherwise the Red Tag analysis can also have a counterproductive effect on the planned project. The Lean advisors are still divided on the question of how often such sorting should take place. Some advise holding such a Red Tag event every quarter; others advise laying out the red tags openly so that every employee has the opportunity to mark an element at any time.

The method of red tagging is also used in the socio-political area as a labeling approach in order to be able to mark opponents in a publicly effective way and then to be able to (let them) be switched off. The expression is particularly common in relation to right-wing authoritarian regimes such as Latin American military dictatorships , where the symbol color red has a particularly obvious meaning because the opponents are often marked as “ communists ”; However, the method can also be used under populist conditions with other political implications. Opposition, disagreeable political actors or critics of the regime are publicly marked as “red” so that they can then be intimidated by established threat scenarios and followed up, which can lead to political murder . Strategies of political-social stigmatization interlock with mechanisms of impunity for regime-friendly activists. Today the fight against political opponents under the presidency of Rodrigo Duterte in the Philippines is perceived as “red tagging”.

literature

- Pascal Dennis: Lean Production Simplified, Third Edition: A Plain-Language Guide to the World's Most Powerful Production System. CRC Press, 2016, pp. 45-47.

- Thomas L. Jackson: 5S for Healthcare - Lean Tools for Healthcare Series. 1st edition. CRC Press, 2009, p. 43 ff.

- Werner Pepels: Handbook Customer Service Management: Basics of After Sales Marketing. Symposium Publishing, 2014, p. 207.

- Brice Alvord: Planning and Implementing 5S. Lulu.com, 2010, p. 59 ff.

- Uwe Dombrowski: Lean Development: Current status and future developments. Springer-Verlag, 2015.

Web links

- Velaction , accessed May 10, 2016

- IT Managers Inbox , accessed May 10, 2016

- 5S Supply , accessed May 11, 2016

- FIVE HILLS HEALTH REGION , accessed May 11, 2016

- asq-1302.org , accessed May 9, 2016

Individual evidence

- ↑ Werner Pepels: Handbook Customer Service Management: Basics of After Sales Marketing. Symposium Publishing, 2014, p. 207.

- ^ Taiichi Ohno: Toyota Production System - Beyond Large-Scale Production. Productivity Press, Cambridge Massachusetts 1988.

- ↑ itmanagersinbox.com/103/5s-system-step-1-the-sort-step/ IT Managers Inbox

- ↑ http://www.asq-1302.org/wp-content/uploads/2010/09/The-5Ss-of-Workplace-Organization.pdf ASQ Section 1302

- ↑ lean.org

- ↑ velaction.com

- ↑ velaction.com

- ↑ Red Tagging - You're It! ( Memento from June 7, 2016 in the Internet Archive ) 5S Supply

- ↑ asq-1302.org

- ↑ velaction.com

- ↑ Uwe Dombrowski: Lean Development: Current status and future developments. Springer, Heidelberg 2015.

- ^ Pascal Dennis: Lean Production Simplified, Third Edition: A Plain-Language Guide to the World's Most Powerful Production System. CRC Press, Boca Raton 2016, pp. 45-47.

- ↑ asq-1302.org

- ↑ Rappler Talk: Resisting red-tagging in universities. In: Rappler. October 26, 2018, accessed on July 23, 2019.

- ↑ “We'll Live!” A Filipino bishop speaks about neocolonial perseverance and anti-religious populism. In: taz , July 21, 2019, accessed on July 23, 2019.

- ^ CHR warns of grave implications of red-tagging groups. In: Philstar Global. April 17, 2019, accessed on July 23, 2019.