Rowing machine (shipbuilding)

A rowing machine is a machine installed on board a ship that is used to increase the muscular strength exerted by the helmsman when adjusting the rudder angle (“lay the oar”) so that the counteracting mechanical and hydrodynamic forces are overcome.

The steering effect on the ship is achieved by putting the rudder in the propulsion current and in the propeller current . The control forces result from the pressure distribution around the rudder, which today are mainly designed as hydrofoils . Electrohydraulic plunger or rotary vane rudder machines are mainly used today. Two independent rowing machines are prescribed by the classifications.

Hydraulic rowing machines

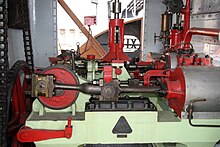

Plunger rowing machine

It consists of an electrically driven pressure oil pump ( hydraulic pump ) and the steering gear with two differential pistons or four plunger pistons . A stroke-adjustable axial piston pump is often used as the pressure oil pump . The piston rods of the plunger rowing machine act for straight guidance on movable sliding blocks that act on the tiller . The tiller handle is positively connected to the rudder shaft, so that a hydraulic volume flow can be set when the stroke of the axial piston pump is adjusted. This creates a path for the pistons, which in turn causes the rudder stock to rotate. There is a feedback on the rudder stock , except in the case of mechanical feedback, there is often a resolver that shows the actual value of the rudder angle in real time on the bridge on the rudder position indicator .

Rotary vane rowing machine

In the hydraulic rotary vane rowing machine, a stroke adjustment of the axial piston pump causes a rotary movement of the rudder stock. The pressure that builds up in the hydraulic spaces between the rotating vanes that can be moved with the rudder stock and the partition walls attached to the housing creates a force and, via the lever arm, a moment. On the suction side, the hydraulic oil flows back into the hydraulic system.

literature

- Ship operating technology manual . Seehafenverlag, Hamburg 2006.

- GL building regulations, chap. 2 (machine systems) . Germanischer Lloyd, Hamburg.